Concrete has the advantages of convenient construction, good integrity, and high compressive strength. It has been widely used in construction engineering, bridge engineering, and water-conservancy engineering; and it plays an important role in development of the national economy (Niu, 2003). However, the durability of concrete is a serious problem, one which can cause serious damage to concrete structures and lead to huge economic loss (Bassuoni and Nehdi, 2009; Du et al., 2014 ). In recent decades, the durability of concrete has become a hot topic in civil engineering research. Concrete durability is affected by being in a saturated state and experiencing freeze–thaw cycles (Hong et al., 2012 ). In China, freeze–thaw damage affects the durability of hydraulic structures, which has become one of the major engineering problems, especially in North China (Niu, 2003; Yan et al., 2014 ). Therefore, more attention should be paid to improving the durability of concrete.

Based on experimental results, it is known that after freeze–thaw cycles, concrete's uniaxial compressive strength and tensile strength are significantly decreased (Qin et al., 2005 ). For ordinary concrete, the dynamic modulus of elasticity is reduced to 60% and the weight loss up to 50%. When the freeze–thaw cycles increase, the strain value of ordinary concrete, which corresponds to the peak stress point, is significantly increased in the uniaxial compressive test; but the strain that corresponds to the peak stress decreases gradually in the uniaxial tensile test (Qin et al., 2005 ). With the increase of freeze–thaw cycles, the stress–strain curve of concrete becomes flattened; and the peak point is decreased and shifted to the right (Li et al., 2011 ). This response indicates that the compressive strength of concrete has been decreased, the strain at the peak point increases, and the deformation modulus decreases obviously. Not only the uniaxial stress state but also the multiaxial stress state of concrete have been studied (Qin et al., 2004 ).

The freeze–thaw cycle does not exist in isolation. It is always in the company of other factors, such as salt. Therefore, many scholars at home and abroad have done many works on the coupling of freeze–thaw with other factors (Sun et al., 1999

; Hartell et al., 2011

; Gao et al., 2013

; Ming et al., 2016

). Based on experimental results of the effect of solution concentration on concrete durability, MacInnis and Whiting (1979) and Marchand et al. (1999)

pointed out that the higher concentration of salt solution may not produce greater damage to concrete. For example, the freeze–thaw damage has the greatest effect when NaCl concentration is about 3%. Chatterji (1984) pointed out that after freeze–thaw cycles, the strength of concrete containing salt solution is less than that of concrete containing water; and the higher the concentration of the solution, the less the strength of the concrete. Unlike previous studies that used only one salt type, two different salt types were used in the laboratory test to investigate the frost-resistance of concrete (Mu et al., 2001

; Niu et al., 2013

). The results show that different salt solutions have different effects on the frost-resistance of concrete. For sodium sulfate solution, the relative dynamic elasticity modulus of concrete decreases rapidly after 300 freeze–thaw cycles. For the sodium chloride solution with a concentration of 3.5%, there is no aggravated damage, just serious spalling at the concrete surface (Mu et al., 2001

). Compared with other salts, the mass fraction of 5% MgSO

Previous studies indicated that the compressive strength of concrete decreases remarkably under freeze–thaw cycles; and the durability of concrete decreases obviously—most obviously in the salt environment (Liang and Yuan, 2005). However, there is little in the literature referring to the comparison result of the effect of different salt types and environmental factors on concrete durability. In this paper, the compressive strength of concrete under different environment conditions was obtained. On that basis, the comparison result of the effect of different salt types on concrete durability was obtained; and the key factor affecting the durability was determined.

2 Experimental designs 2.1 Characteristics of concrete mixturesThe cement is ordinary Portland cement (P·O 42.5) produced by Qilianshan Corporation in Gansu Province, China. The performance index of the cement used is shown in Table 1.

|

|

Table 1 P·O 42.5 Portland cement performance index |

The sand is well-graded, medium river sand with a fineness modulus of 2.7. The stone is a continuous grading gravel, 5~20 mm. Running water was used to mix these raw materials.

2.2 Sample preparationThe concrete proportioning was m (water): m (cement): m (sand): m (stone) = 0.420: 1.000: 1.152: 2.449; the details of the concrete mixture are listed in Table 2.

|

|

Table 2 Concrete mixture |

Specimens with 100mm×100mm×100mm cubes were prepared in the laboratory. Raw materials included Portland cement, silica sand, and stone. All the specimens were cured for one day in the natural condition before being demolded and then cured for another 27 days at 20±1 °C with a relative humidity at 95%±5%.

2.3 Test programTo determine the salt-erosion damage on concrete durability, NaCl, CaCl

(1) One group remained immersed, with the specimens put into the different salt solutions; the test time was 120 days.

(2) One group underwent the freeze–thaw cycles test. During the test, the freezing temperature was about −10 °C, lasting for 12 hours; the thawing temperature was 20 °C, lasting for 12 hours; the total test time was 120 days.

(3) One group underwent the wet–dry cycles test. One test cycle lasted for 48 hours, during which the sample was immersed in the saline solution for 24 hours and then removed from it for 24 hours; the test time was 120 days.

During the continuous immersion tests, the sulfate solution had to be changed once a month to ensure the mass fraction was unchanged. When the test time reached 30, 60, 90, and 120 days, the specimens were removed and underwent the compressive strength testing with a loading rate of 0.5 MPa/s. During the test events, when the two duplicate samples' tolerance bias was over 5 MPa, that result was rejected. The equipment used in the test is shown in Figure 1.

|

Figure 1 The equipment used in the test |

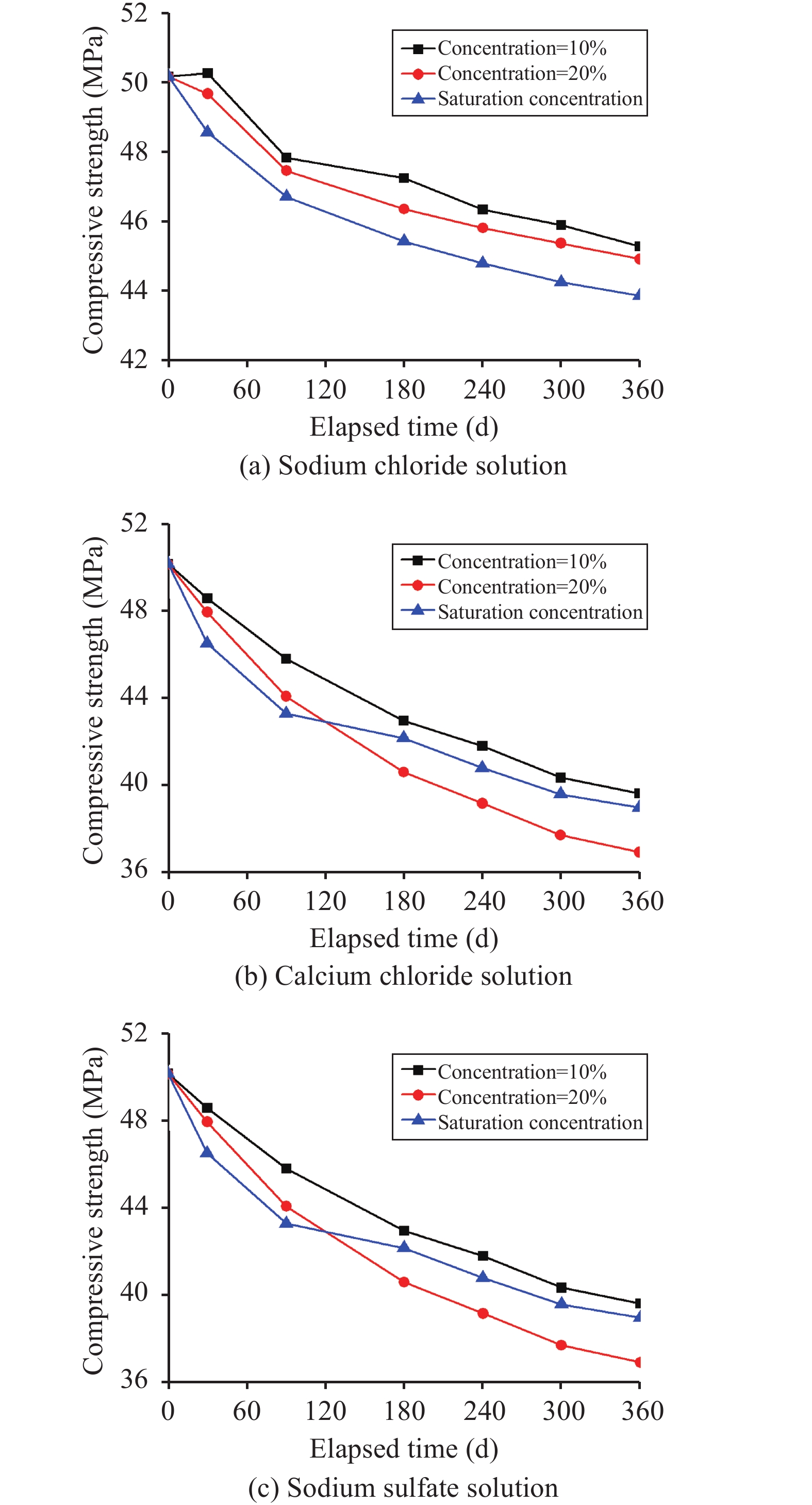

When immersed in the salt solution—whether in sodium chloride, calcium chloride, or sodium sulfate solution—the concrete was subjected to the corrosive action of the salt. From Figure 2, it can be seen that with the increasing immersion time, the degree of corrosion damage is increasing; and the compressive strength of the concrete decreased gradually. As a result, the loss rate of strength is increasing. However, there are some differences in loss rate of strength with different salt types. For example, when the solution concentration was 20%, the elapsed time from the beginning to 360 days, the changes of compressive strength and strength-loss rate, respectively, were as follows: sodium sulfate samples, 50.15 MPa to 36.89 MPa, 0% to 26.44%; calcium chloride samples, 50.15 MPa to 43.06 MPa, 0% to 14.14%; and sodium chloride samples, 50.15 MPa to 44.92 MPa, 0% to 10.43%. These findings indicate that the sodium sulfate solution had an important effect on the concrete strength.

|

Figure 2 Change law of compressive strength in different salt environments |

From the test results, it can be seen that for one kind of salt, with the same immersion time, the compressive strength of the concrete decreases with the increase in solution concentration, and the strength-loss rate increases with the increase in concentration. For example, when the calcium chloride samples are immersed for 180 days, the compressive strength for specimens under three different concentrations (10%, 20%, and saturation) is 47.1 MPa, 45.8 MPa, and 44.6 MPa, respectively; and the strength-loss rate is 6.22%, 8.71%, and 11.15%, respectively. As can be seen from Figure 2, the influence of the Na

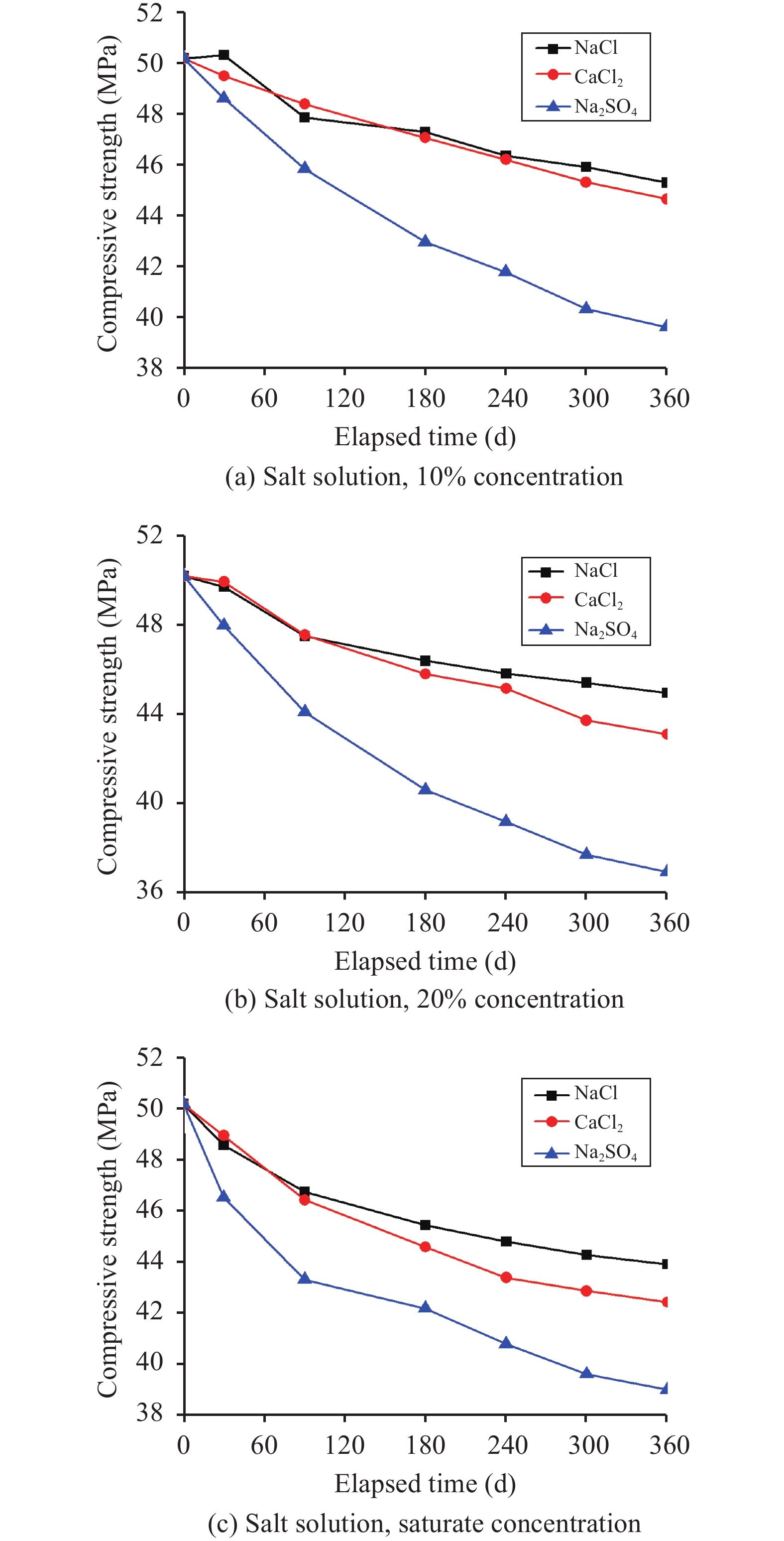

From Figure 3, it can be seen that due to the corrosive effect of salt, with the same concentration and same immersed time, the compressive strength of concrete immersed in the corrosive sodium sulfate solution is decreased the maximum; the middle is the calcium chloride solution; and the minimum is the sodium chloride solution. Taking the condition with the solution concentration of 10% and soaking time of 360 days, for example, the compressive strength of concrete immersed in the sodium sulfate, calcium chloride, and sodium chloride solutions is 39.59 MPa, 44.64 MPa, and 45.28 MPa, respectively; and the strength-loss rate in sodium sulfate, calcium chloride, and sodium chloride solutions is 21.11%, 11.00%, and 9.73%, respectively. From the results mentioned above, it can be concluded that under the same conditions, the sodium sulfate has the largest corrosive effect on concrete durability, compared with the calcium chloride and sodium chloride.

|

Figure 3 Change law of the compressive strength under different salt environments |

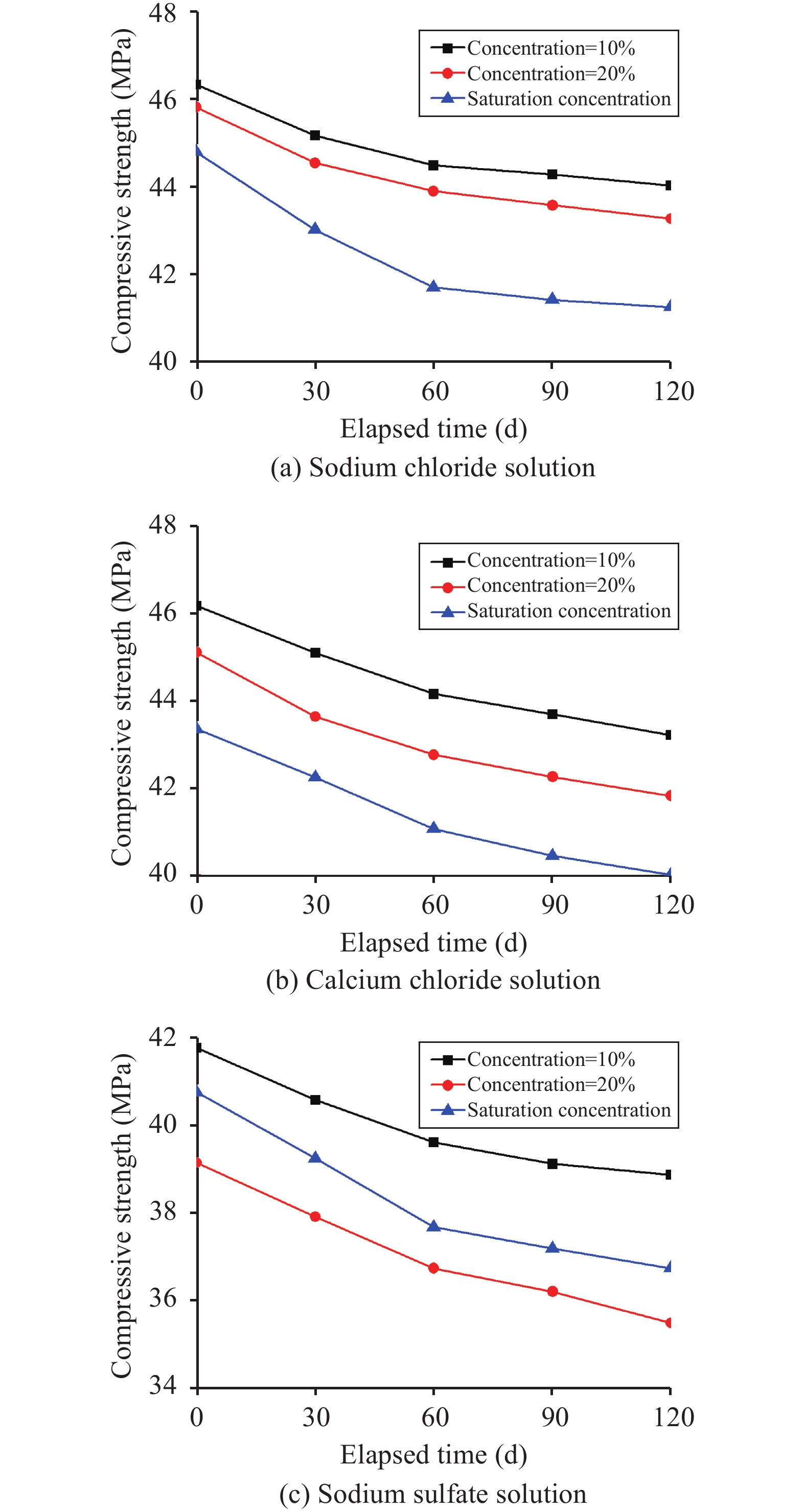

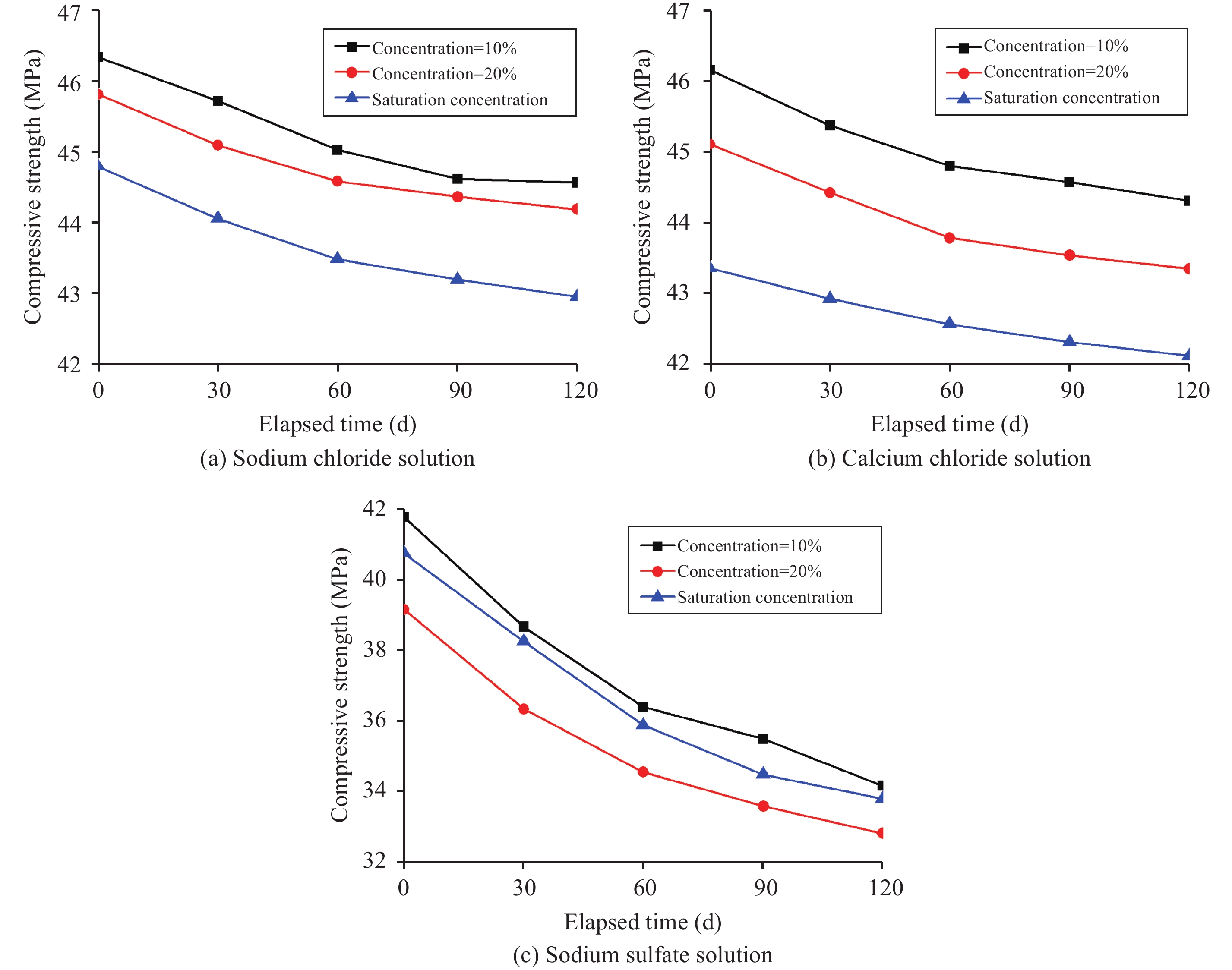

For constructions located in the semi-arid region, concrete often is subjected to the salt and freeze–thaw environment. As a result, the service time of constructions in these areas has been decreased (Li et al., 2011 ; Hong et al., 2012 ). To evaluate the durability of constructions placed in this work condition, a series of tests were done in the laboratory. From Figure 4, we can see that whether the concrete is immersed in the sodium chloride, calcium chloride, or sodium sulfate solution, with the increase of freezing and thawing cycles, the degree of damage to the concrete under the action of the freeze–thaw cycles is greater. This damage manifests as the compressive strength of the concrete decreases, and the strength-loss rate increases. Take the result of the 20% concentration, for example: after 120 days' freeze–thaw cycles, the compressive strength and its loss ratio are as follows. For the samples immersed in the sodium sulfate solution, the compressive strength drops from 39.20 MPa to 35.50 MPa, a loss ratio of 9.35%; for the samples immersed in the calcium chloride solution, the compressive strength drops from 45.11 MPa to 41.83 MPa, a loss ratio of 7.27%; and for the samples immersed in the sodium chloride solution, the compressive strength drops from 45.81 MPa to 43.25 MPa, a loss ratio of 5.60%. Under the same conditions, the sodium sulfate solution produces the strongest damage to the concrete strength.

|

Figure 4 Compressive strength of concrete immersed in different solutions after freeze–thaw cycles |

For each salt type, with the same freeze–thaw cycles, the compressive strength decreases with the increase in solution concentration; and the loss rate of strength increases with the increase in concentration. For example, the samples immersed in the calcium chloride solution: after 60 days' freeze–thaw cycles, the compressive strength under three different concentrations (10%, 20%, and saturation) was 44.22 MPa, 42.81 MPa, and 41.13 MPa, respectively; and the loss ratio of compressive strength was 4.41%, 5.24%, and 5.63%, respectively.

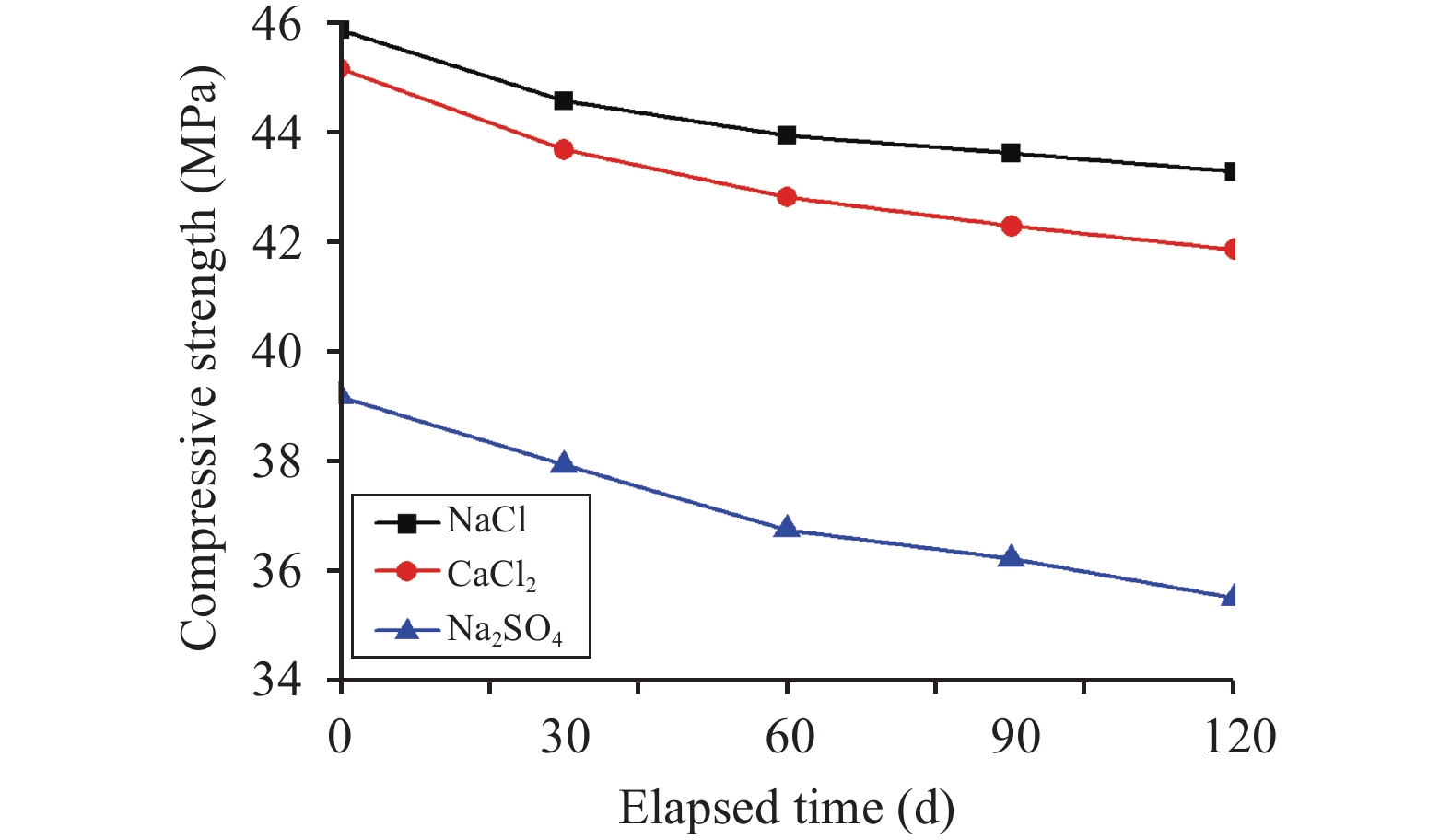

From Figure 5, it can be seen that with the same salt concentration, the compressive strength decreases with the increase of freeze–thaw cycles. There is little difference in the decreasing value. As shown in Figure 5, when the freeze–thaw cycle time reached 120 days, the compressive strength of the samples immersed in the sodium sulfate solution, calcium chloride solution, and sodium chloride solution was 35.49 MPa, 41.83 MPa, and 43.25 MPa, respectively. This means that the strength-loss rate caused by the sodium sulfate was the largest, followed by calcium chloride; and the corrosion caused by the sodium chloride was the minimum.

|

Figure 5 Variation of compressive strength with different freeze–thaw cycles, 20% concentration |

In the semi-arid region, concrete constructions often are exposed to the wet–dry conditions (Hartell et al., 2011 ). In this paper, a series of tests were carried out in the laboratory to simulate this work condition; and the test results are presented in Figure 6. It can be seen from Figure 6 that whether the concrete is immersed in the sodium chloride, calcium chloride, or sodium sulfate solution, as the wet–dry cycles increased, the degree of damage to the concrete became stronger; and the compressive strength was reduced gradually. When the wetting–drying cycles reached 120 days, consider the solution concentration of 20%, for example: the change of compressive strength and the strength-loss rate was as follows. The sample immersed in the sodium sulfate solution decreased from 39.15 MPa to 32.81 MPa, with a loss ratio of 16.2%; the sample immersed in the calcium chloride solution decreased from 45.11 MPa to 43.35 MPa, with a loss ratio of 3.90%; and the sample immersed in the sodium chloride solution decreased from 45.81 MPa to 44.18 MPa, with a loss ratio of 3.55%. Based on the results presented above, it can be concluded that the loss rate of compressive strength of the concrete immersed in the sodium sulfate solution is the largest; and the loss ratio is relatively small when the sample was immersed in the chloride solution.

|

Figure 6 Compressive strength of concrete immersed in different solutions after wet–dry cycles |

When the wet–dry cycles' time reached 120 days, the compressive strength of the concrete samples immersed in three different concentrations (10%, 20%, and saturation) is 44.32 MPa, 43.35 MPa, and 42.12 MPa, respectively; and the strength-loss rate is 2.91%, 3.94%, and 4.03%, respectively. Due to the effect of the salt corrosion, the compressive strength of the concrete decreased with the increase in concentration; and the strength-loss rate increased with increasing concentration. The compressive strength and strength-loss rate of the sample immersed in the sodium sulfate varied greatly, but the change of the sample immersed in the chlorine solution was relatively small.

3.5 Analysis of the factors affecting concrete durabilityAs shown in the previous section, no matter which environment (continuous immersing, freeze–thaw cycles, or wet–dry cycles), the compressive strength of concrete decreased with the increase of elapsed time. However, which condition was the key factor affecting the concrete durability was still unknown. In this section, according to the laboratory test results, we will analyze the change law of compressive strength under the three different environmental conditions.

To determine the key factor that affects the durability of concrete, we set three different environmental conditions. According to the test results, the compressive strength-loss ratio with 10% Na2SO4 concentration was obtained, as shown in Figure 7. From the results, it can be seen that the loss ratio increases with elapsed time. Compared with the other two factors, the wet–dry cycle is the key factor that affects the durability of concrete. This finding can be explained in that the early wet and dry cycles may slow the degradation process of concrete caused by the alkali–silica reaction (ASR). However, as the elapsed time increases, the alkali–silica reaction is exacerbated; when the swelling stress surpasses the tensile strength, a crack is formed. When the concrete is subjected to the wet and dry conditions, the water can easily migrate into the concrete and accelerate the alkali–silica reaction. In the dry environment, the drying shrinkage can advance the development of cracking. Both wetting and drying promote that development; as a result, the degree of damage to concrete in the wet–dry condition is larger than that in the freeze–thaw condition.

|

Figure 7 Compressive strength-loss ratio under 10% Na2SO4 concentration |

(1) With the increase of immersion time and salt concentration, the compressive strength of concrete decreased gradually, the strength-loss rate increased, and the damage degree increased. The compressive strength indicates that sodium sulfate has the strongest corrosive effect on the concrete durability, followed by calcium chloride; and sodium chloride has the weakest corrosion.

(2) Under the action of freeze–thaw cycles, as the freeze–thaw time and the number of cycles increased, the compressive strength of the concrete decreased gradually; the strength-loss rate increased. Due to the corrosion of the salt, the strength-loss rate of the concrete immersed in the sodium sulfate solution was the largest, followed by that in the calcium chloride; and the sodium chloride corrosion was the minimum.

(3) Under the action of the wet–dry cycles, the compressive strength was reduced gradually; and the degree of damage to the concrete increased with the increase of wet–dry cycles; also, the strength-loss rate increased. Concrete compressive strength decreases with the increase in concentration, and the strength-loss rate increases with the increase in concentration.

(4) No matter what the environmental conditions are, the compressive strength-loss ratio increases with elapsed time. Compared with the other two environmental factors, the wet–dry cycle is the key factor that affects the durability of concrete. As a result, in the practice of engineering, more measures should be applied to protect concrete, especially in the wet–dry conditions.

Acknowledgments:This work is supported by the Key Research Program of Frontier Sciences of the Chinese Academy of Sciences (QYZDYSSW-DQC015) and the funding of the State Key Laboratory of Frozen Soil Engineering (No. SKLFSE-ZT-17).

Bassuoni MT, Nehdi ML. 2009. Durability of self-consolidating concrete to different exposure regimes of sodium sulfate attack. Materials and Structures, 42(8): 1039-1057. DOI:10.1617/s11527-008-9442-2 |

Chatterji S. 1984. Freezing of aqueous solutions in a porous medium Part I. Freezing of air-entraining agent solutions. Cement and Concrete Research, 15(1): 13-20. DOI:10.1016/0008-8846(85)90003-1 |

Du P, Yao Y, Wang L, et al. 2014. Research progress on the prediction of concrete's service life based on freeze-thaw damage. Journal of Yangtze River Scientific Research Institute, 31(4): 77-84. DOI:10.3969/j.issn.1001-5485.2014.04.017 |

Gao RD, Li QB, Zhao SB. 2013. Concrete deterioration mechanisms under combined sulfate attack and flexural loading. Journal of Materials in Civil Engineering, 25(1): 39-44. DOI:10.1061/(ASCE)MT.1943-5533.0000538 |

Hartell JA, Boyd AJ, Ferraro CC. 2011. Sulfate attack on concrete: effect of partial immersion. Journal of Materials in Civil Engineering, 23(5): 572-579. DOI:10.1061/(ASCE)MT.1943-5533.0000208 |

Hong JX, Miao CW, Liu JP, et al. 2012. Degradation law of mechanical properties of concrete subjected to freeze-thaw cycles. Journal of Building Materials, 15(2): 173-178. DOI:10.3969/j.issn.1007-9629.2012.02.005 |

Li WT, Sun W, Jiang JY. 2011. Damage of concrete experiencing flexural fatigue load and closed freeze/thaw cycles simultaneously. Construction and Building Materials, 25(5): 2604-2610. DOI:10.1016/j.conbuildmat.2010.12.007 |

Liang YN, Yuan YS. 2005. Effects of environmental factors of sulfate attack on deterioration of concrete mechanical behavior. Journal of China University of Mining & Technology, 34(4): 452-457. DOI:10.3321/j.issn:1000-1964.2005.04.010 |

Liu WD, Su WT, Wang YM. 2008. Research on damage model of fiber concrete under action of freeze-thaw cycle. Journal of Building Structures, 29(1): 124-128. DOI:10.3321/j.issn:1000-6869.2008.01.018 |

MacInnis C, Whiting JD. 1979. The frost resistance of concrete subjected to a deicing agent. Cement and Concrete Research, 9(3): 325-336. DOI:10.1016/0008-8846(79)90125-X |

Marchand J, Pigeon M, Bager D, et al. 1999. Influence of chloride solution concentration on deicer salt scaling deterioration of concrete. ACI Materials Journal, 96(4): 429-435. DOI:10.14359/642 |

Ming F, Deng YS, Li DQ, 2016. Mechanical and durability evaluation of concrete with sulfate solution corrosion. Advances in Materials Science and Engineering, 2016: Article ID 6523878. DOI: 10.1155/2016/6523878.

|

Mu R, Miao CW, Liu JP, et al. 2001. Effect of NaCl and Na2SO4 solution on the frost resistance of concrete and its mechanism

. Journal of the Chinese Ceramic Society, 29(6): 523-529. DOI:10.3321/j.issn:0454-5648.2001.06.004 |

Niu DT, 2003. Durability and Life Forecast of Reinforced Concrete Structure. Beijing: Science Press,pp:35–38.

|

Niu DT, Jiang L, Fei QN. 2013. Deterioration mechanism of sulfate attack on concrete under freeze-thaw cycles. Journal of Wuhan University of Technology-Materials Science Edition, 28(6): 1172-1176. DOI:10.1007/s11595-013-0839-6 |

Qin LK, Song YP, Yu CJ, et al. 2004. Mechanical property and failure criterion for concrete under biaxial compressive stresses after cyclic freezing and thawing. Engineering Mechanics, 21(2): 188-195. DOI:10.3969/j.issn.1000-4750.2004.02.032 |

Qin LK, Song YP, Chen HR, et al. 2005. Influence of freezing and thawing cycle on mechanical properties of concrete. Chinese Journal of Rock Mechanics and Engineering, 24(S1): 5048-5053. |

Sun W, Zhang YM, Yan HD, et al. 1999. Damage and its restraint of concrete with different strength grades under double damage factors. Cement and Concrete Composites, 21(5–6): 439-442. DOI:10.1016/S0958-9465(99)00033-5 |

Yan WJ, Niu FJ, Zhang XJ, et al. 2014. Advances in studies on concrete durability and countermeasures against freezing-thawing effects. Sciences in Cold and Arid Regions, 6(4): 398-408. DOI:10.3724/SP.J.1226.2014.00398 |

Zhang YQ, Yu HF, Sun W, et al. 2011. Frost resistance of concrete under action of magnesium sulfate attack. Journal of Building Materials, 14(5): 698-702. DOI:10.3969/j.issn.1007-9629.2011.05.024 |

2017, Vol. 9

2017, Vol. 9