Article Information

- QiuBo Yan, Feng Zhang, KangWei Tang, ShuJuan Wang, Yan Liu . 2017.

- Experimental investigation on static and dynamic resilient moduli of compacted fine soil

- Sciences in Cold and Arid Regions, 9(3): 297-306

- http://dx.doi.org/10.3724/SP.J.1226.2017.00297

Article History

- Received: November 21, 2016

- Accepted: December 21, 2016

2. School of Transportation Science and Engineering, Harbin Institute of Technology, Heilongjiang, Harbin 150090, China

Static resilient modulus is a crucial parameter during designation of a road foundation, and is used to evaluate subgrade strength and stability. The importance of subgrade strength and stability is reflected in the numerous studies that investigated the static resilient modulus of soils (Broms, 1964; Graham and Au, 1985; Cole et al., 1986 ; Simonsen and Janoo, 2002).

Recently, researchers have found that the dynamic effects such as the impact of wheels play a significant role on subgrade soil behavior, such as strength and deformation. These dynamic effects may cause pavement defects, the weakness of using function, and under traffic load, eventually leading to road breakage. Therefore, to improve the designation and construction process, it is necessary to investigate the dynamic modulus of subgrade soil, and the relationships between static and dynamic modules.

The dynamic resilient modulus concept was first introduced by Seed et al. (1962) . This concept was eventually accepted by scientists studying road, and became one of the main parameters of subgrade soil. Chen et al. (2006) determined the loading sequence of an indoor triaxial repeated loading test of subgrade. Ling et al. (2007) investigated the resilient modulus of subgrade soil with different properties and found that partial stress and lateral stress both have significant effects on resilient modulus of subgrade soil, so does the water content, and the degree of compaction. Zhang SZ (2008) analyzed the influence of water content, lateral stress, cyclic stress on dynamic resilient modulus with UTM-100, provided reference for test method and the standard value of dynamic resilient modulus of subgrade soil. Mao et al. (2009) studied the resilient modulus of subgrade soil in different water content, compaction, and freeze-thaw cycles. Ling et al. (2010) studied the influencing factors and regularity of dynamic resilient modulus of subgrade soil, which solved the parameter problem. Liu et al. (2013) studied the dynamic resilient modulus of cohesive subgrade soil under different water content. The relationship between dynamic resilient modulus of the subgrade and the matrix suction was also discussed. Wang et al. (2016) studied the impact of plastic index, freeze-thaw cycles and confining pressure on dynamical resilient modulus and established the static and dynamic resilient modulus parameter transformation theory.

In cold regions, the freezing and thawing of the soil can lead to a significant change in soil engineering properties. Johnson et al. (1979) conducted silt and clay soil subgrade tests in field and laboratory, established the mechanical model of the pavement design after freezing thawing cycle, and provided the function expression of resilient modulus and Poisson's ratio with stress state, water content and dry density. Simonsen and Isacsson (2001) investigated three kinds of soil subjected to freeze-thaw cycles by three triaxial tests and analyzed the influence of freeze-thaw cycles on the resilient modulus. The research results of Hicks and Monismith (1971), Muhanna et al. (1999) , Brown and Hyde (1975) and Raad and Zeid (1990) all revealed that resilient modulus of subgrade soil is influenced by stress, physical condition (water content and compaction) and material properties. George (2004) and Han (2005) both built a predictive model of resilient modulus by stress condition and physical properties of subgrade soil. Andrei et al. (2004) compared 13 models with measured data, concluding that the SUPERPAVE Model is most accurate. Yau and Quintus (2004) also agreed with Andrei et al. (2004) and improved the SUPERPAVE Model.

In this paper, we investigated the static and dynamic resilient modulus of fine soil, adapted to the new design code and maintenance system of highway subgrade in China. A series of static and dynamic resilient modulus tests were carried out according to the standard laboratory test methods (JTG E40-2007 and JTG D30-2015, respectively). The effects of initial water content, compactness and freeze-thaw cycles on the static and dynamic resilient moduli of fine soil were investigated and analyzed. Finally, an empirical mathematical relationship between static and dynamic resilient moduli was proposed.

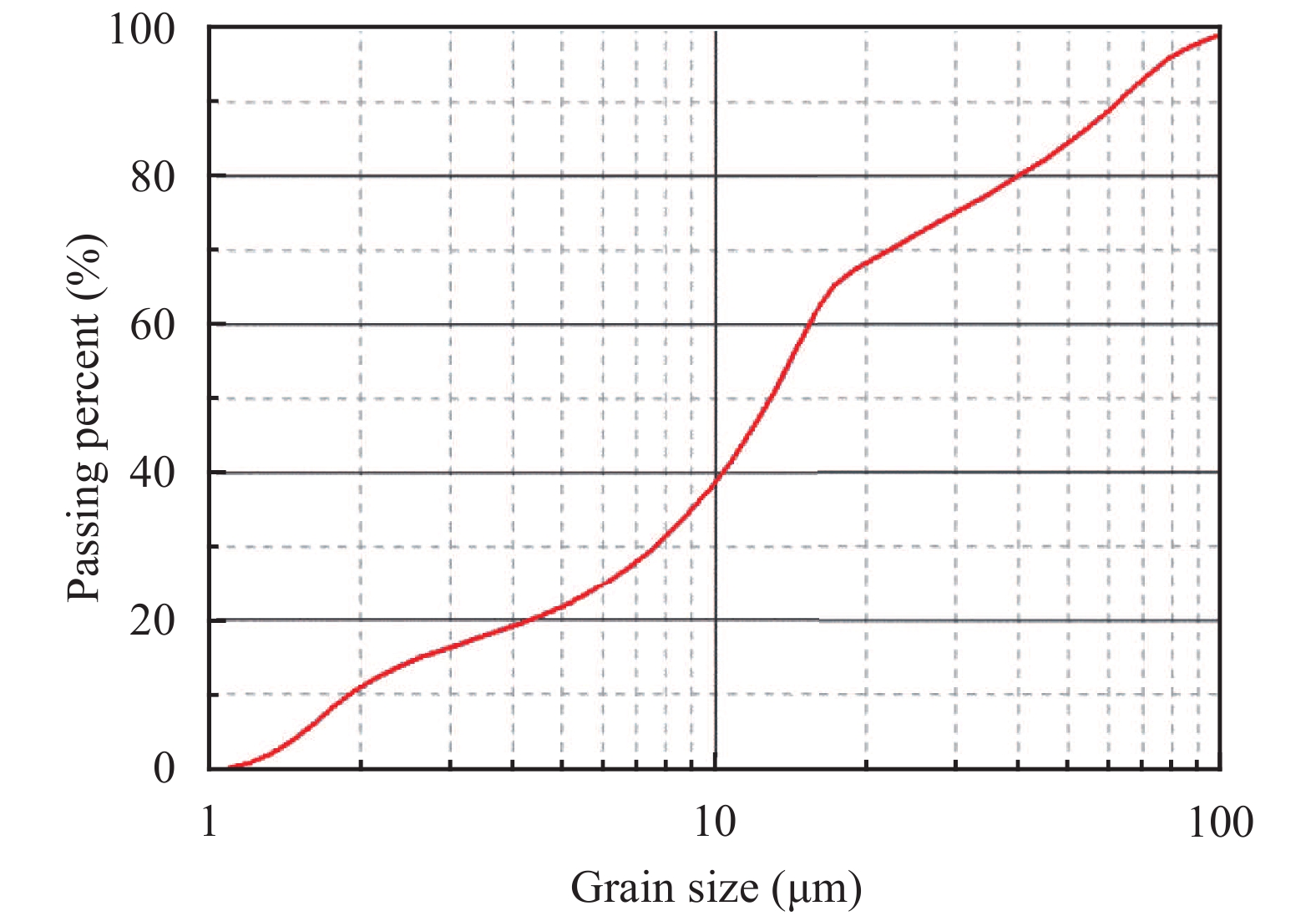

2 Laboratory experiments 2.1 MaterialsThe fine soil used in the present study was taken from Harbin in Heilongjiang Province, a widely used subgrade material in northeastern China. According to the Test Methods of Soils for Highway Engineering (JTG E40-2007) issued by the Ministry of Transport, China, we conducted a series of tests to figure out its physical properties: its specific gravity is 2.75, liquid limit is 36.08%, and plastic limit is 25.19%. The maximum dry-unit weight of soil sample was determined to be 1,730 kg/m3 at the optimum water content of 16.5%. Figure 1 shows the distribution curves of particle size.

|

| Figure 1 Distribution curves of particle size |

The soil specimen preparation, freeze-thaw test, static resilient modulus tests and dynamic resilient modulus tests were carried out in the Key Laboratory of Highway Construction and Maintenance Technology in seasonal frozen soil regions (Changchun), China.

The procedure of preparing soil samples was performed according to the Tests Methods of Soils for Highway Engineering (JTGE40-2007) issued by the Ministry of Transport, China. The air-dried soil sample was passed through a sieve with mesh opening of 0.5 mm, then separated into three parts, and mixed thoroughly with the appropriate amount of distilled water to achieve the initial water content of 16.5%, 19.8%, and 23.1%, respectively. Then soil samples were stored in three closed containers for 12 hours to ensure uniform moisture distribution in the samples.

For the static modulus tests, in the first step, all soils prepared before should be put into a steel mold with a diameter of 150 mm and height of 170 mm, we made them three different dry densities of 1.70 g/cm3, 1.63 g/cm3, 1.56 g/cm3 by put different qualities soils respectively, next all soil samples were reconstituted and compacted into cylindrical specimens in a press machine in which a steel pad helped keep their height at 12 mm. The specimens were then covered with preservative film, and sealed to prevent water evaporation. Figure 2 shows the apparatus for the static moduli test.

|

| Figure 2 Apparatus for static moduli test. 1: Copper molds; 2: Pad; 3: Covered specimen; 4: Press machine; 5: Low temperature freezer; 6: Carrier board; 7: California bearing ratio machine |

For the dynamic modulus tests, all soil samples with a diameter of 100 mm and height of 200 mm were reconstituted and compacted into cylindrical specimens using a steel mold in five layers, we also made them three different dry densities of 1.70 g/cm3, 1.63 g/cm3, 1.56 g/cm3 by put different qualities soils respectively. The specimens were then covered with preservative film to prevent water evaporation.

2.3 Freeze-thaw cycleThe covered specimens were quickly placed into a low temperature freezer (Figure 2) with a temperature of −20 °C. During the freeze-thaw cycle, specimens were placed in the freezer at a temperature of −20 °C for 12 hours to experience one freezing process. The specimens were then placed into a room with a temperature of about 20 °C for 12 hours to experience one thawing process. This freezing and thawing procedure was repeated until the designed number of freeze-thaw cycles was reached.

To compare the influence of freeze-thaw cycle, a control group of compacted soil specimens with the initial water content of 16.5%, 19.8%, and 23.1%, that did not experience the freeze-thaw cycles, were quickly placed into the curing box.

2.4 Apparatus and testing procedure 2.4.1 Static resilient modulus testIn this study, a CBR machine (California bearing ratio machine, Figure 2) was employed to conduct the static modulus test program. The specimen was placed on the platform of the CBR machine, and a carrier board (Figure 2) with a diameter of 50 mm and height of 80 mm connected the penetration rod and the top of the specimen to transfer the force between them. The dial indicator of the CBR machine monitored pressure, and two digital indicators located at symmetrical positions on the loading broad monitored displacement. A pre-loaded pressure of about 153 kPa was placed on the specimen before formal loading for 1 min. After pre-loading, the load was removed so the dial indicated zero, and then the formal test was carried out with loading and removing a progressive pressure (increasing 35.7 kPa each time, nine times in total) from 0 kPa to 321.3 kPa. Data was recorded by three indicators 1 minute after loading, and then renewed 1 minute after removing pressure.

Table 1 shows the test conditions for each group of specimens in the study of static modulus. Note that the specimens were tested at initial water content of 16.5%, 19.8%, and 23.1%, dry density of 1.70 g/cm3, 1.63 g/cm3, and 1.56 g/cm3, with the number of freeze-thaw cycles of 0, 1, 3, 5, 7, and 10.

| Group number | Water content (%) | Dry density (g/cm3) | Freeze-thaw (times) |

| 1 | 16.5 | 1.70 | 0 |

| 2 | 19.8 | 1.63 | 0 |

| 3 | 23.1 | 1.63 | 0 |

| 4 | 16.5 | 1.70 | 3 |

| 5 | 19.8 | 1.63 | 3 |

| 6 | 23.1 | 1.63 | 3 |

| 7 | 16.5 | 1.63 | 0 |

| 8 | 16.5 | 1.56 | 0 |

| 9 | 16.5 | 1.63 | 3 |

| 10 | 16.5 | 1.56 | 3 |

| 11 | 16.5 | 1.70 | 1 |

| 12 | 16.5 | 1.70 | 5 |

| 13 | 16.5 | 1.70 | 7 |

| 14 | 16.5 | 1.70 | 10 |

In this study, a UTM-100 (Figure 3) was employed to conduct the dynamic modulus test. As presented in Figure 3, the apparatus is capable of carrying out a stress-controlled cyclic dynamic loading test. According to the method of Ling et al. (2010) , 16 loading sequences made up of four confining pressures including 15, 30, 45, and 60 kPa and four different cyclic stresses including 30, 55, 75, and 105 kPa were applied.

|

| Figure 3 Apparatus for static moduli test. 1,2: Copper molds; 3,4: Specimen; 5: Low temperature freezer; 6: Curing box; 7: UTM-100 |

Table 2 shows the different test conditions for each group of specimens in the study of dynamic modulus. Note that the specimens were tested at an initial water content of 16.5%, 19.8%, and 23.1%, dry density of 1.70 g/cm3, 1.63 g/cm3, and 1.56 g/cm3, and number of freeze-thaw cycle of 0, 1, 3, 5, 7, and 10.

| Group number | Water content (%) | Dry density (g/cm3) | Freeze-thaw (times) |

| 1 | 16.5 | 1.70 | 0 |

| 2 | 19.8 | 1.63 | 0 |

| 3 | 23.1 | 1.63 | 0 |

| 4 | 16.5 | 1.70 | 3 |

| 5 | 19.8 | 1.63 | 3 |

| 6 | 23.1 | 1.63 | 3 |

| 7 | 16.5 | 1.63 | 0 |

| 8 | 16.5 | 1.56 | 0 |

| 9 | 16.5 | 1.63 | 3 |

| 10 | 16.5 | 1.56 | 3 |

| 11 | 16.5 | 1.63 | 1 |

| 12 | 16.5 | 1.63 | 5 |

| 13 | 16.5 | 1.63 | 7 |

| 14 | 16.5 | 1.63 | 10 |

Table 3 shows the test conditions for each soil specimen in the study of dynamic modulus. Note that the specimens were test at loading frequency of 10 Hz, confining pressure of 15, 30, 45, and 60 kPa, and cyclic bias stress of 30, 55, 75, and 105 kPa.

| Loading sequence | Confining stress (kPa) | Cyclic stress (kPa) | Loading frequency (Hz) | Axial stress (kPa) | Loading times (times) |

| 0 | 30 | 50 | 10 | 80 | 1,000 |

| 1 | 60 | 30 | 10 | 90 | 100 |

| 2 | 45 | 30 | 10 | 75 | 100 |

| 3 | 30 | 30 | 10 | 60 | 100 |

| 4 | 15 | 30 | 10 | 45 | 100 |

| 5 | 60 | 55 | 10 | 155 | 100 |

| 6 | 45 | 55 | 10 | 100 | 100 |

| 7 | 30 | 55 | 10 | 85 | 100 |

| 8 | 15 | 55 | 10 | 70 | 100 |

| 9 | 60 | 75 | 10 | 135 | 100 |

| 10 | 45 | 75 | 10 | 120 | 100 |

| 11 | 30 | 75 | 10 | 105 | 100 |

| 12 | 15 | 75 | 10 | 90 | 100 |

| 13 | 60 | 105 | 10 | 165 | 100 |

| 14 | 45 | 105 | 10 | 150 | 100 |

| 15 | 30 | 105 | 10 | 135 | 100 |

| 16 | 15 | 105 | 10 | 120 | 100 |

The specimens were placed into the pressure chamber. After the confining pressure achieved stability, the specimens experienced a 1,000 times pre-loading under a confining pressure of 30 kPa and a cyclic bias stress of 50 kPa, and then a series of cyclic triaxial tests were performed. Each loading sequence was conducted 100 times, regarding the average modulus of the last five times loading as the dynamic modulus under that loading sequence. The axial cyclic stress and displacement of specimen were recorded by the automatic data acquisition system.

3 Determination of resilient modulusAccording to the Test Methods of Soils for Highway Engineering (JTG E40-2007), the resilient deformation can be calculated by the following equation:

| $l = {l_0} - {l_1}$ | (1) |

where, l is the axial resilient deformation, l0 is the axial deformation after loading pressure, and l1 is the axial deformation after removing pressure.

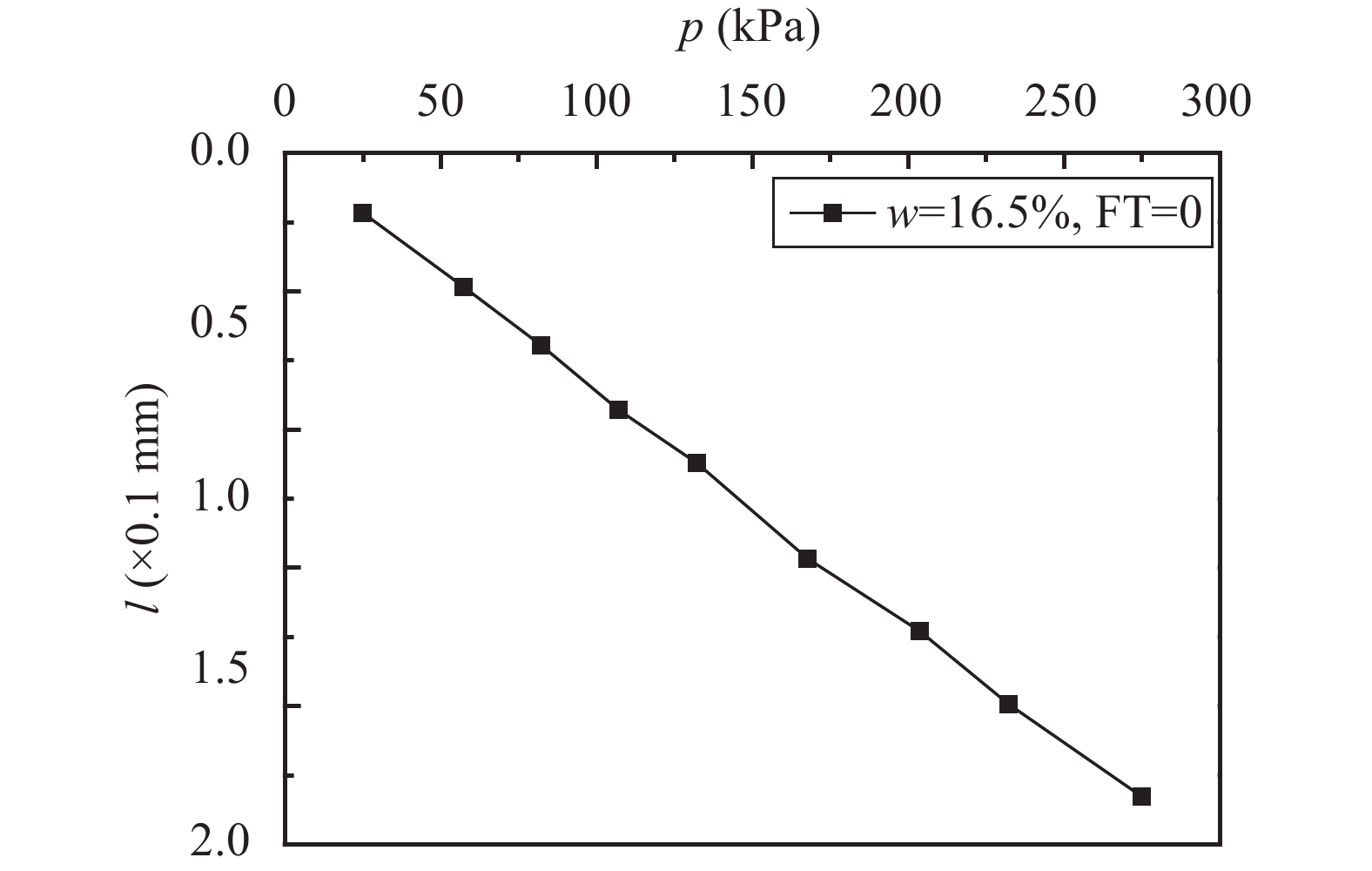

Then, a p-l liner fit curve can be drawn to show the relation between pressure and axial deformation (Figure 4).

|

| Figure 4 The relation curve between pressure and axial resilient deformation (p-l) |

The static resilient modulus is determined by Equation (2).

| ${E_s} = \frac{{{\rm{\uppi }}pD}}{{4l}}(1 - {\mu ^2})$ | (2) |

where, Es is static resilient modulus, p is pressure of the carrier board, D is diameter of the carrier board, equals to 5 cm, l is axial deformation under the pressure, and u is Poisson's ratio of the fine soil, equals to 0.35.

According to the triaxial test, the axial cyclic stress σd and axial cyclic strain εd were obtained from collected data. The dynamic resilient modulus can be calculated from the following equation:

| ${E_d}{\rm{ = }}\frac{{{\sigma _d}}}{{{\varepsilon _R}}}$ | (3) |

where, σd is cyclic stress, σd=σ1−σ3, σ1 is axial stress, σ3 is confining pressure, and εR is the axial displacement. UTM-100 outputs dynamic modulus directly.

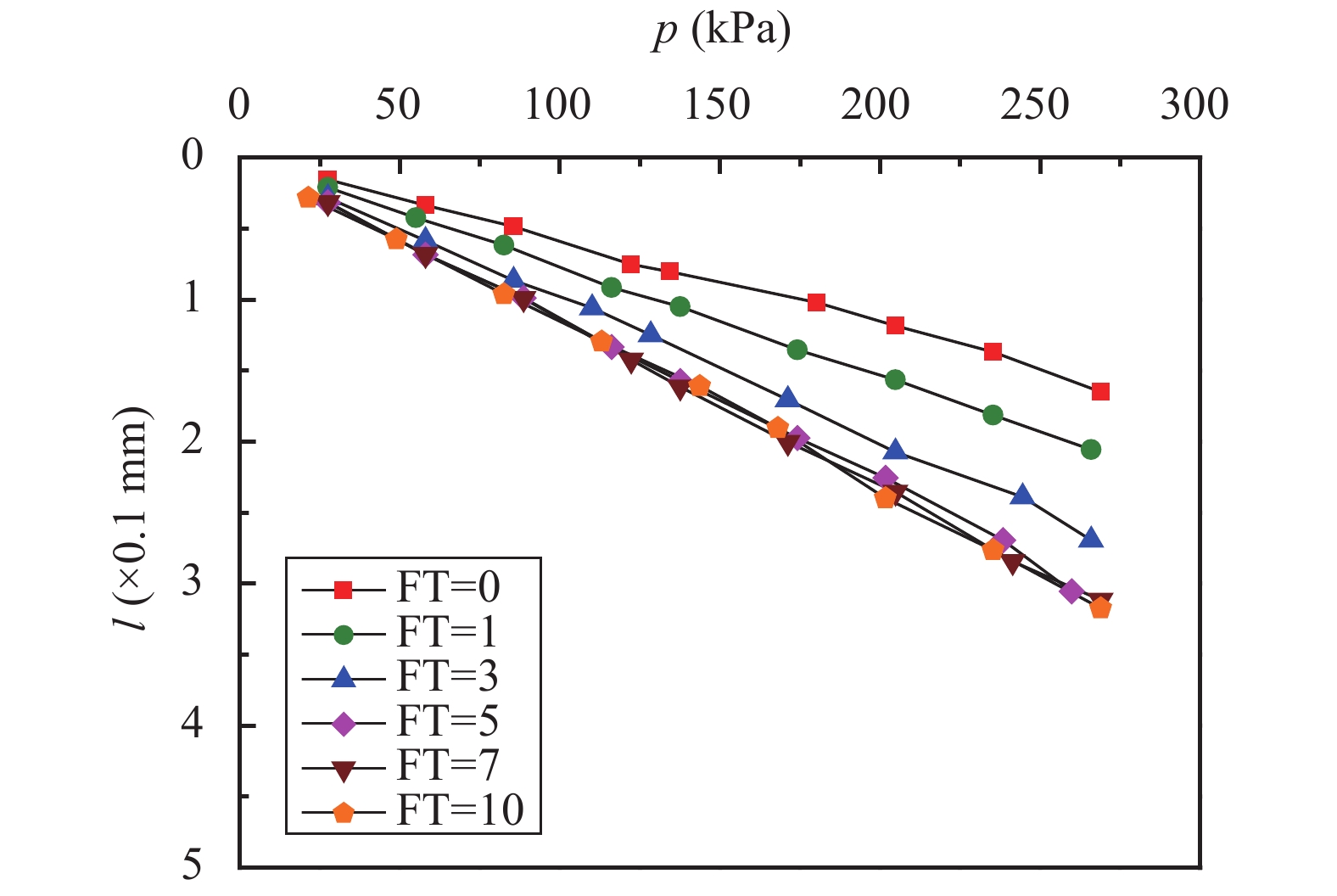

4 Results and analysis 4.1 Static resilient modulus 4.1.1 Effect of freeze-thawThe p-l curves of fine soil at the number of freeze-thaw cycle of 0, 1, 3, 5, 7, and 10 is presented in Figure 5. Note that with increasing number of freeze-thaw, the axial deformation of the specimen in the same axial pressure increases, which shows a decrease in static modulus.

|

| Figure 5 The p-l curves of specimens at number of freeze-thaw of 0, 1, 3, 5, 7, and 10 |

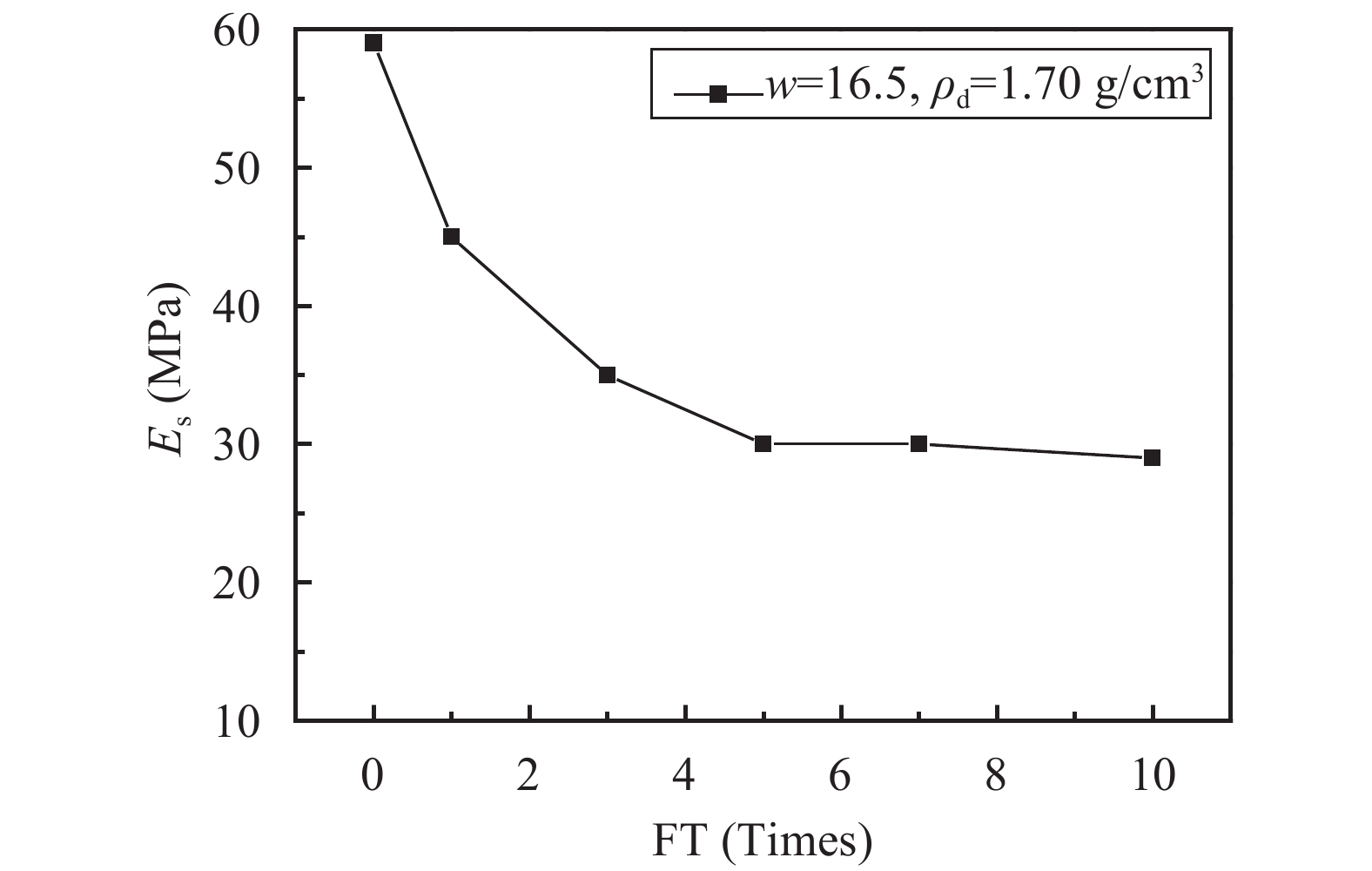

Figure 6 shows the static modulus of specimens with the same water content, dry density and different freeze-thaw times. As presented in Figure 6, when water content is 16.5%, and dry density is 1.70 g/cm3, the static resilient moduli decreases about 24.0%, 41.5%, 48.9%, 49.6%, and 50.3% with number of freeze-thaw increasing from 0 to 1, 3, 5, 7, and 10. The specimens' static modulus became steady after seven times freeze-thaw cycle.

|

| Figure 6 Static resilient modulus at different number of freeze-thaw cycles |

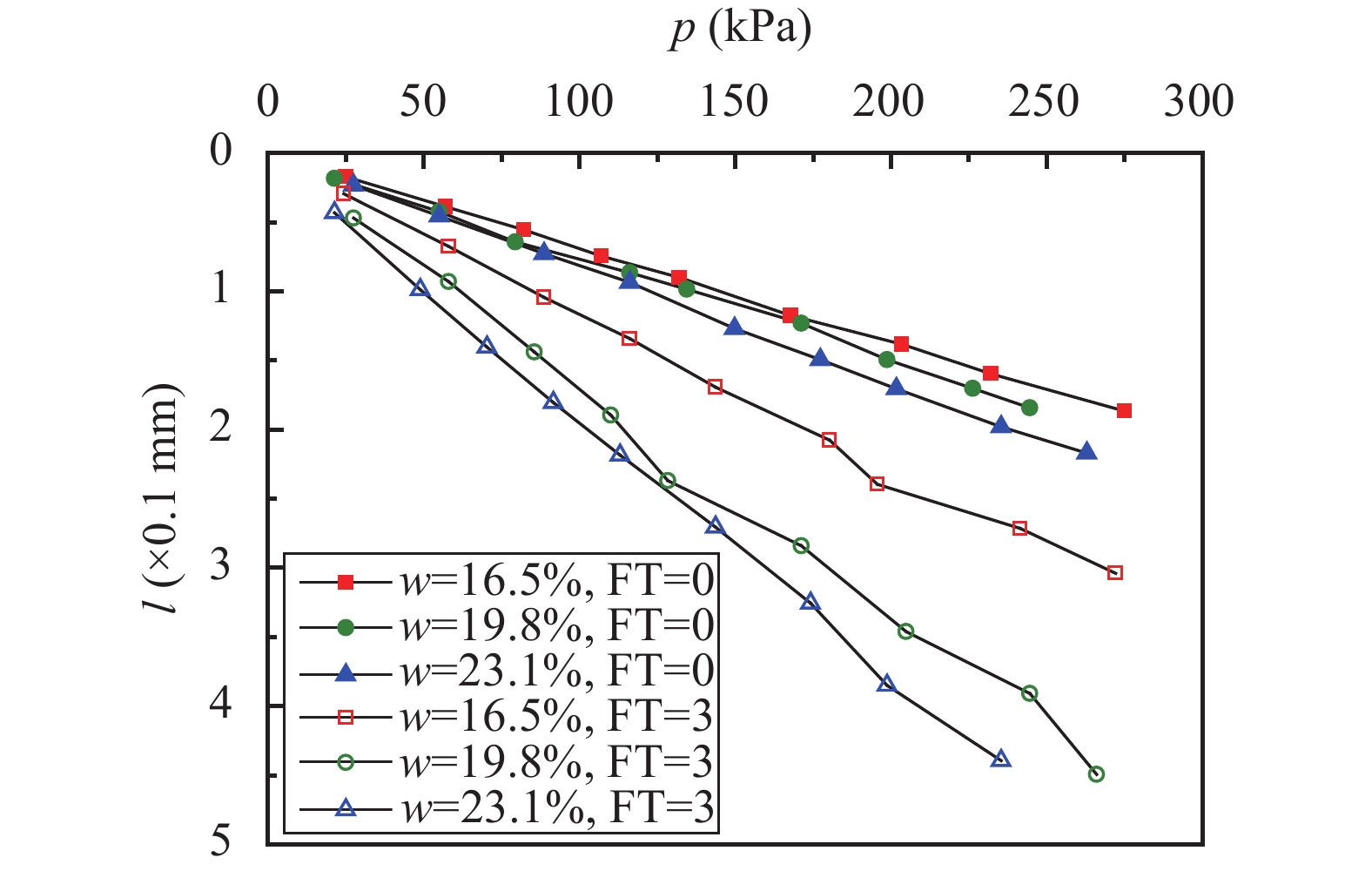

The p-l curves of fine soil at initial water content of 16.5%, 19.8%, and 23.1% is presented in Figure 7. Note that with increasing water content, the axial deformation of the specimen in the same axial pressure increases, which shows a decrease in static modulus.

|

| Figure 7 The p-l curves of specimens at initial water content of 16.5%, 19.8% and 23.1% |

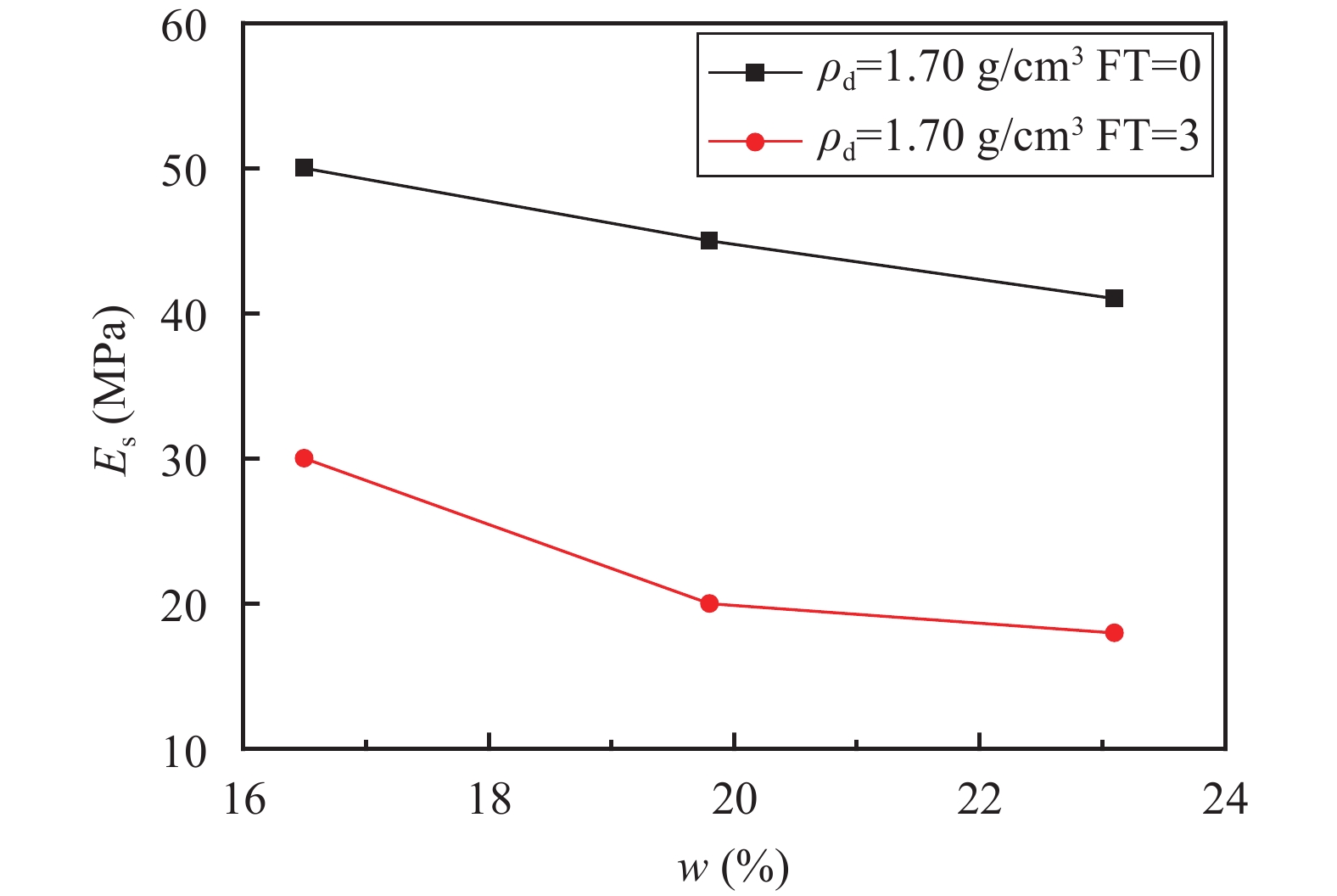

Figure 8 shows the static modulus of specimens with the same dry density, freeze-thaw times and different water content. As presented in Figure 8, when dry density is 1.63 g/cm3, and no freeze-thaw cycle, the static resilient modulus decreases about 10.2% and 17.7% with water content increasing from 16.5% to 19.8%, and 23.1%. While the static resilient modulus decreases about 30.8% and 40.0% with water content increasing from 16.5% to 19.8% and 23.1%, when dry density is 1.63 g/cm3, freeze-thaw cycles is three.

|

| Figure 8 The static resilient modulus at different water content |

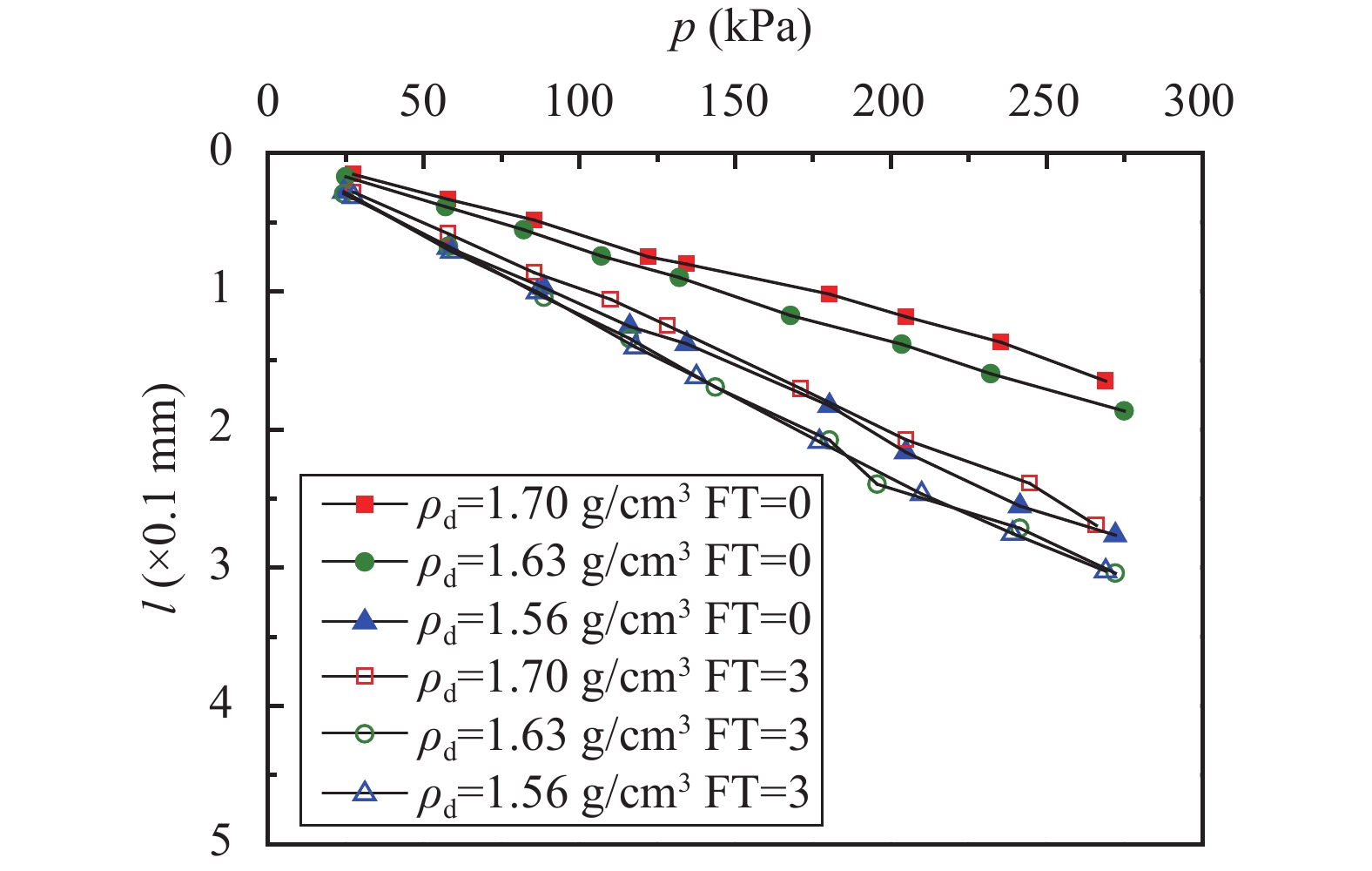

The p-l curves of fine-fine soil at dry density of 1.70 g/cm3, 1.63 g/cm3, and 1.56 g/cm3 are presented in Figure 9. Note that with decreasing dry density, the axial deformation of the specimen in the same axial pressure increases, which shows a decrease in static modulus.

|

| Figure 9 The p-l curves of specimens at different dry density of 1.70 g/cm3, 1.63 g/cm3 and 1.56 g/cm3 |

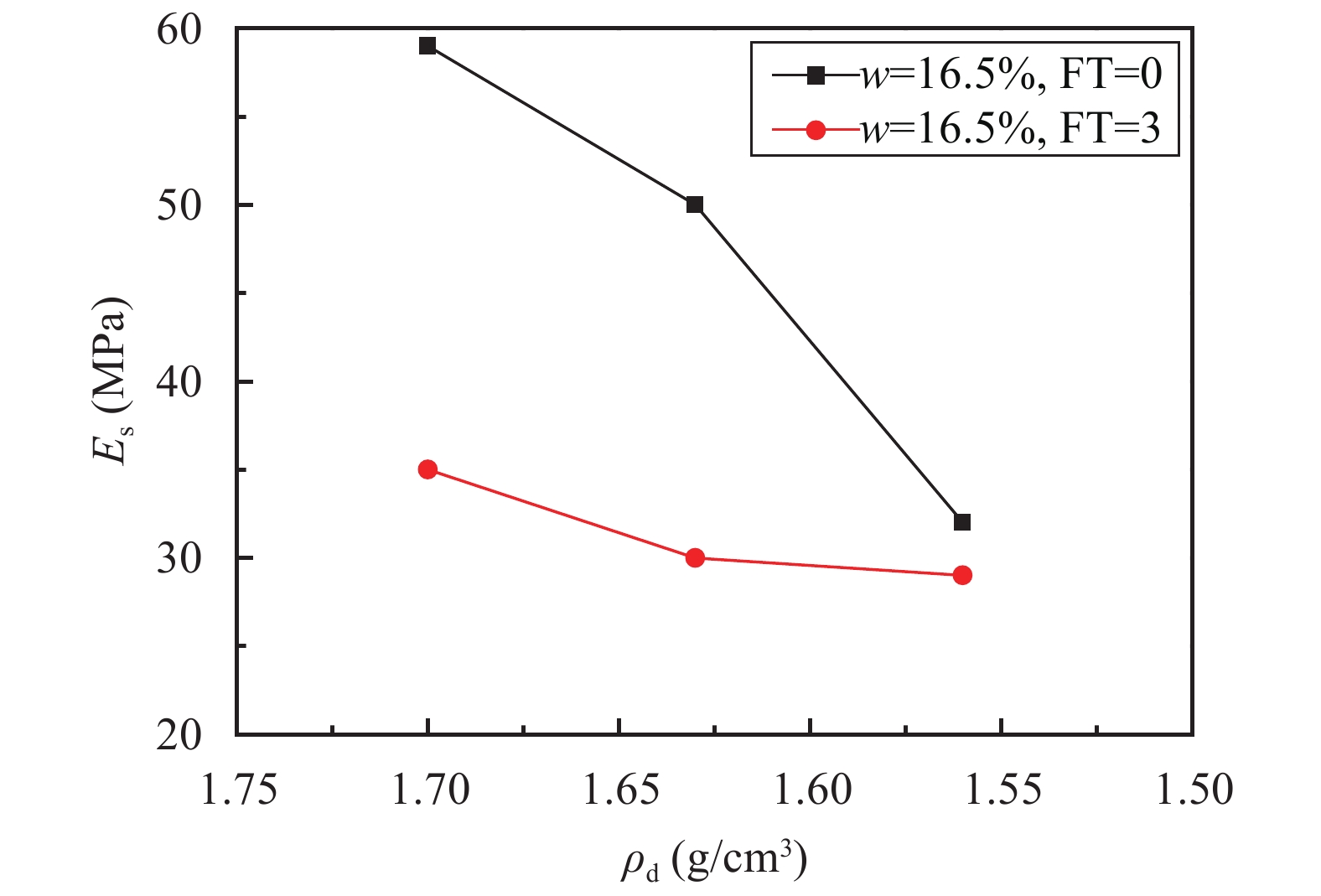

Figure 10 shows the static modulus of specimens with the same water content, freeze-thaw times and different dry density. As presented in Figure 10, when water content is 16.5%, and no freeze-thaw cycle the static resilient modulus decreases about 14.9% and 45.5% with dry density decreasing from 1.70 g/cm3 to 1.63 g/cm3, and 1.56 g/cm3. While the static resilient modulus decreases about 14.4% and 15.0%, with dry density decreasing from 1.70 g/cm3 to 1.63 g/cm3, and 1.56 g/cm3, when water content is 16.5%, freeze-thaw cycles is three.

|

| Figure 10 The static resilient modulus at different dry density |

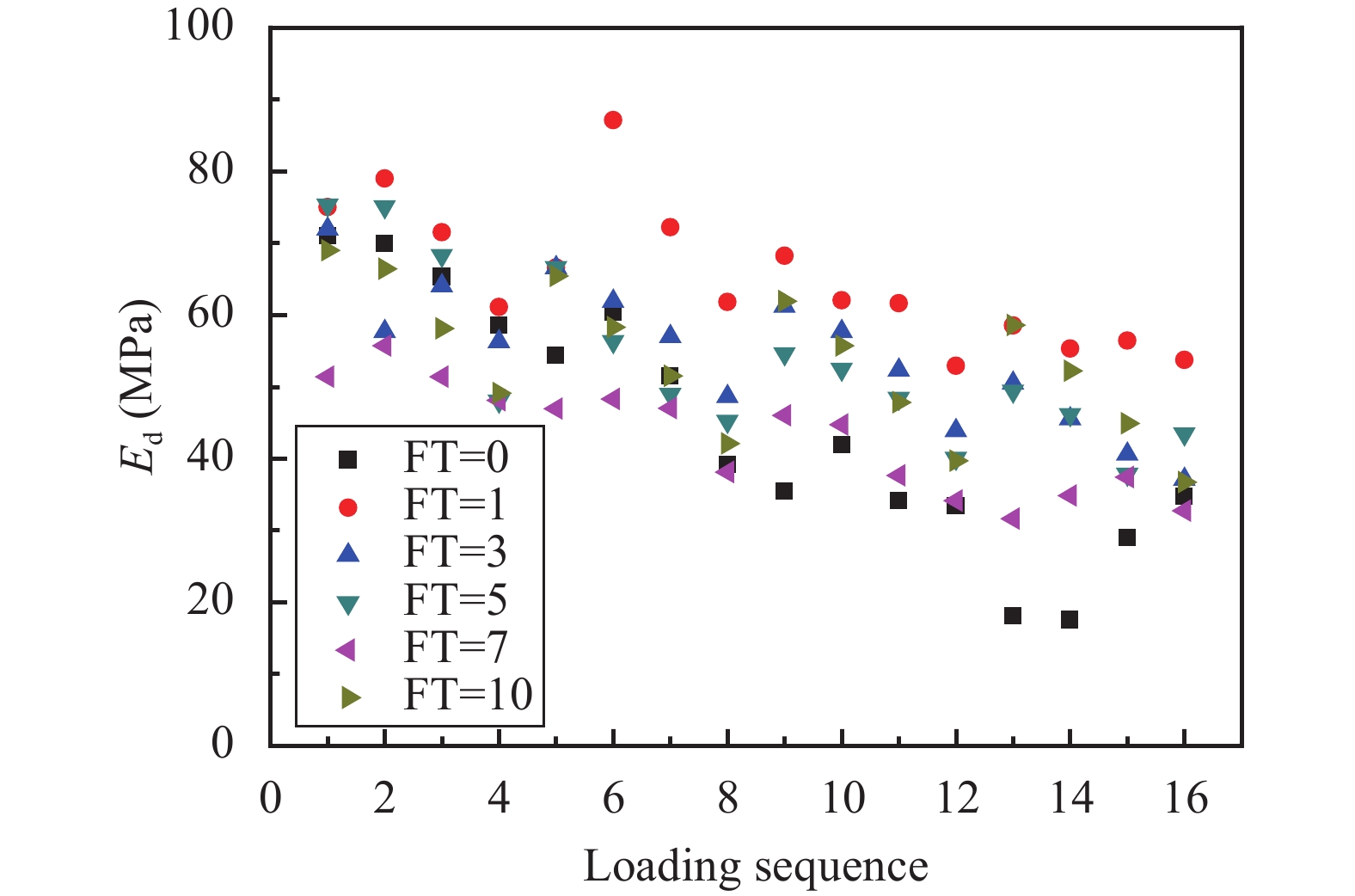

Figure 11 shows the dynamic resilient modulus of fine soil at the number of freeze-thaw cycle of 0, 1, 3, 5, 7, and 10. As presented in Figure 11, the dynamic resilient modulus has no clear damping tendency but still decreases in different levels in most loading sequences. The dynamic resilient moduli decreases 0.0%~30.0%, 0.0%~35.4% and 21.2%~46.0% after experienced 3, 5, and 7 freeze-thaw cycles, respectively.

|

| Figure 11 The dynamic resilient modulus at different number of freeze-thaw cycles |

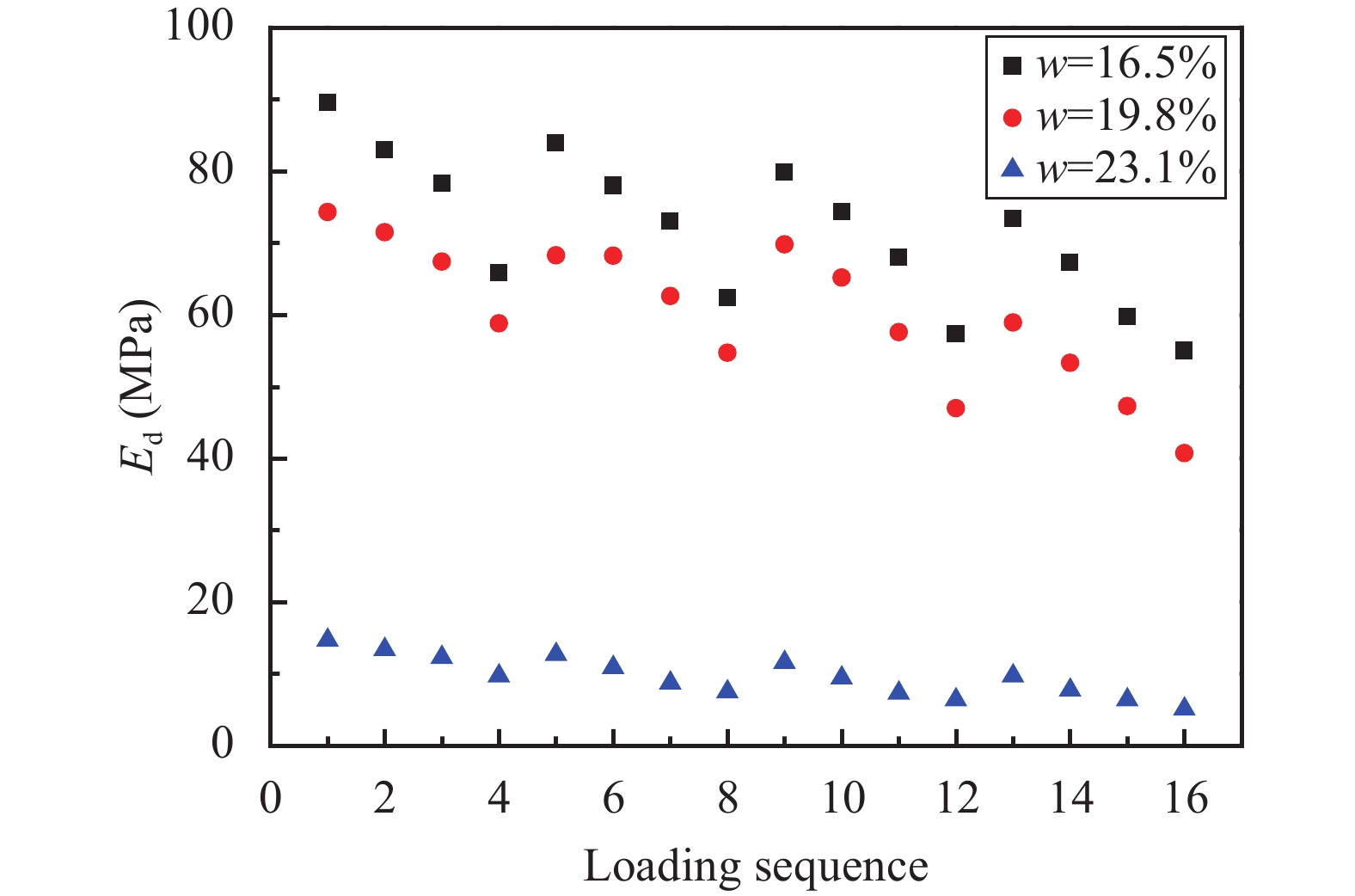

Figure 12 shows the dynamic resilient modulus curves of fine soil at the water content of 16.5%, 19.8%, and 23.1%. As presented in Figure 12, the dynamic resilient modulus in every loading sequence decreases with water content increasing. The maximum dynamic resilient modulus decrease 10.9%~55.7% with water content increasing from 16.5% to 19.8%, while 83.6%~90.8% from 16.5% to 23.1%, and the maximum damp respectively occur in the 1st and 16th loading sequence.

|

| Figure 12 Dynamic resilient modulus of all loading sequences at different water content |

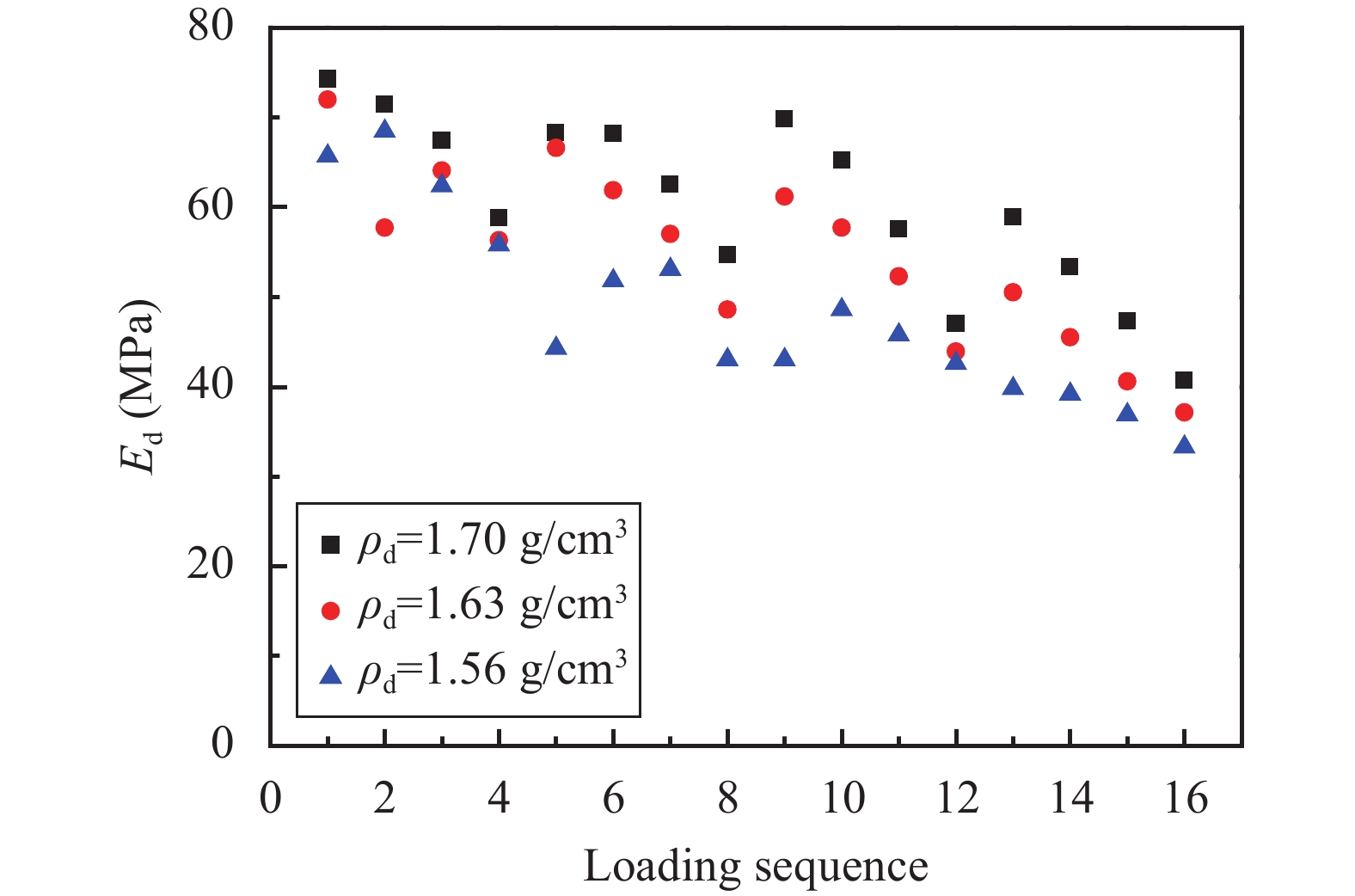

Figure 13 shows the dynamic resilient modulus curves of fine soil at dry density of 1.70 g/cm3, 1.63 g/cm3, and 1.56 g/cm3. As presented in Figure 13, the dynamic resilient modulus in every loading sequence decreases with dry density decreasing. The dynamic resilient modulus decreases 2.5%~14.6% when the dry density decrease from 1.70 g/cm3 to 1.63 g/cm3, 5.2%~38.4% from 1.63 g/cm3 to 1.56 g/cm3, the maximum damping respectively occur in the 14th and 9th loading sequence.

|

| Figure 13 Dynamic resilient modulus of all loading sequences at different dry density |

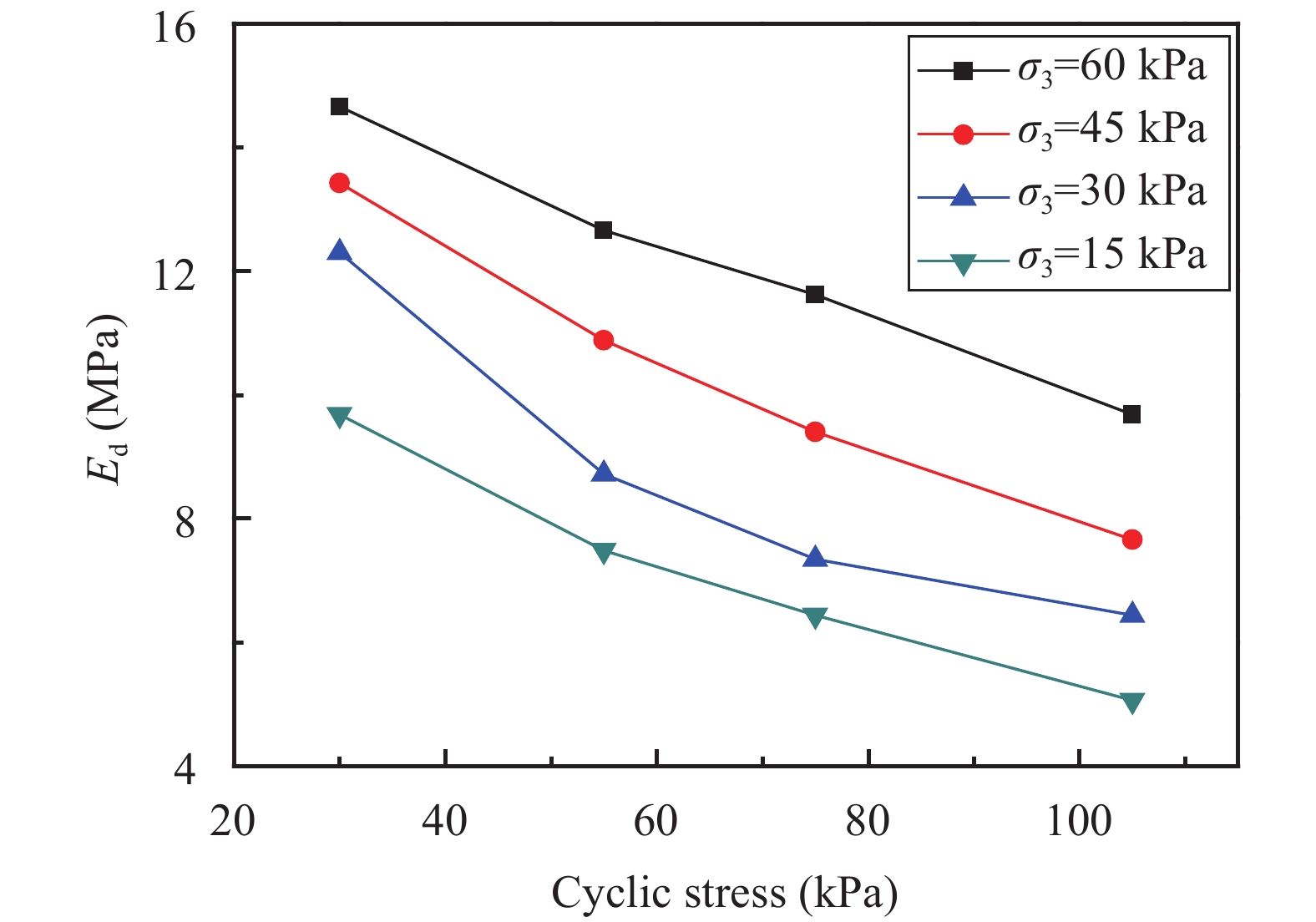

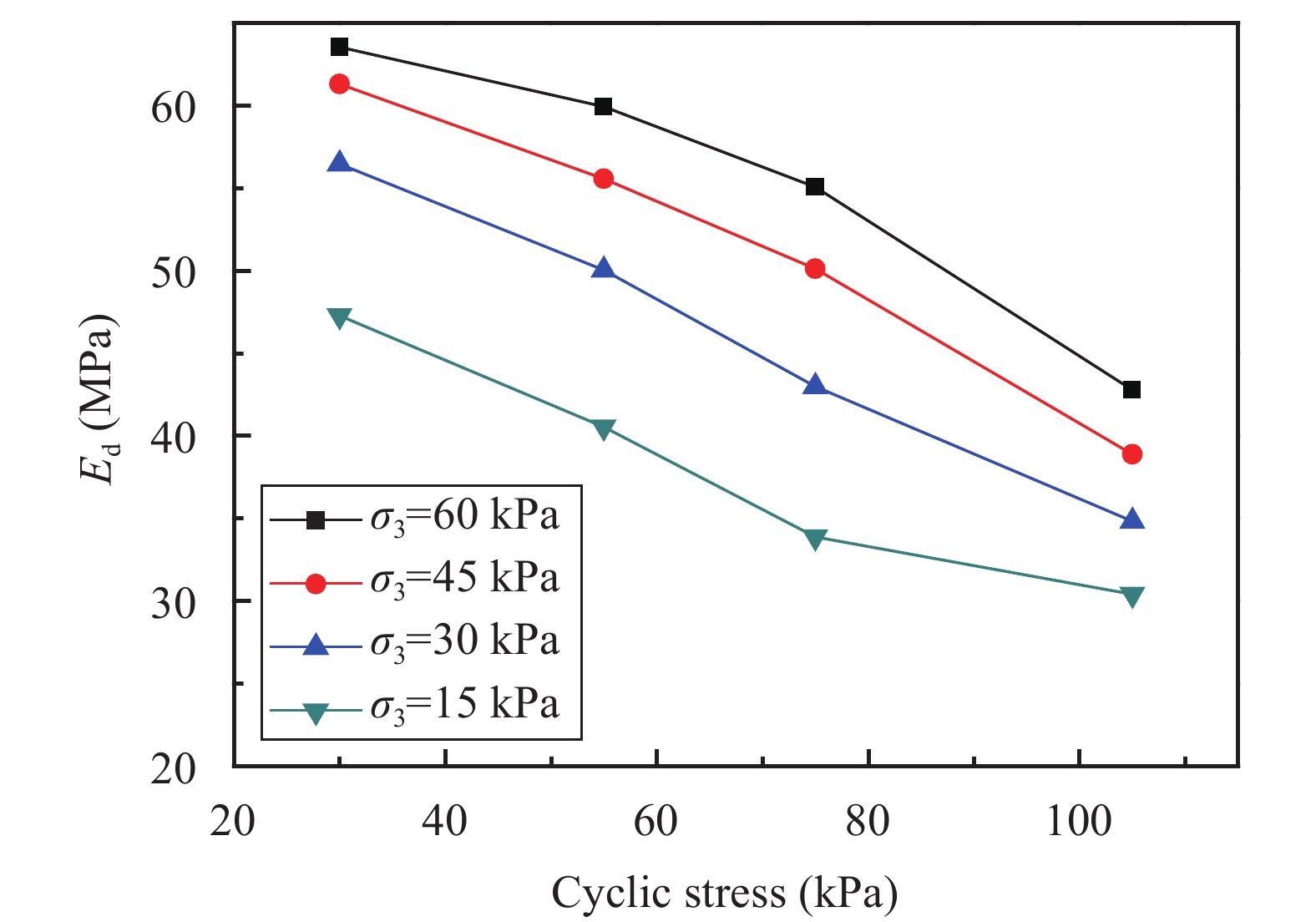

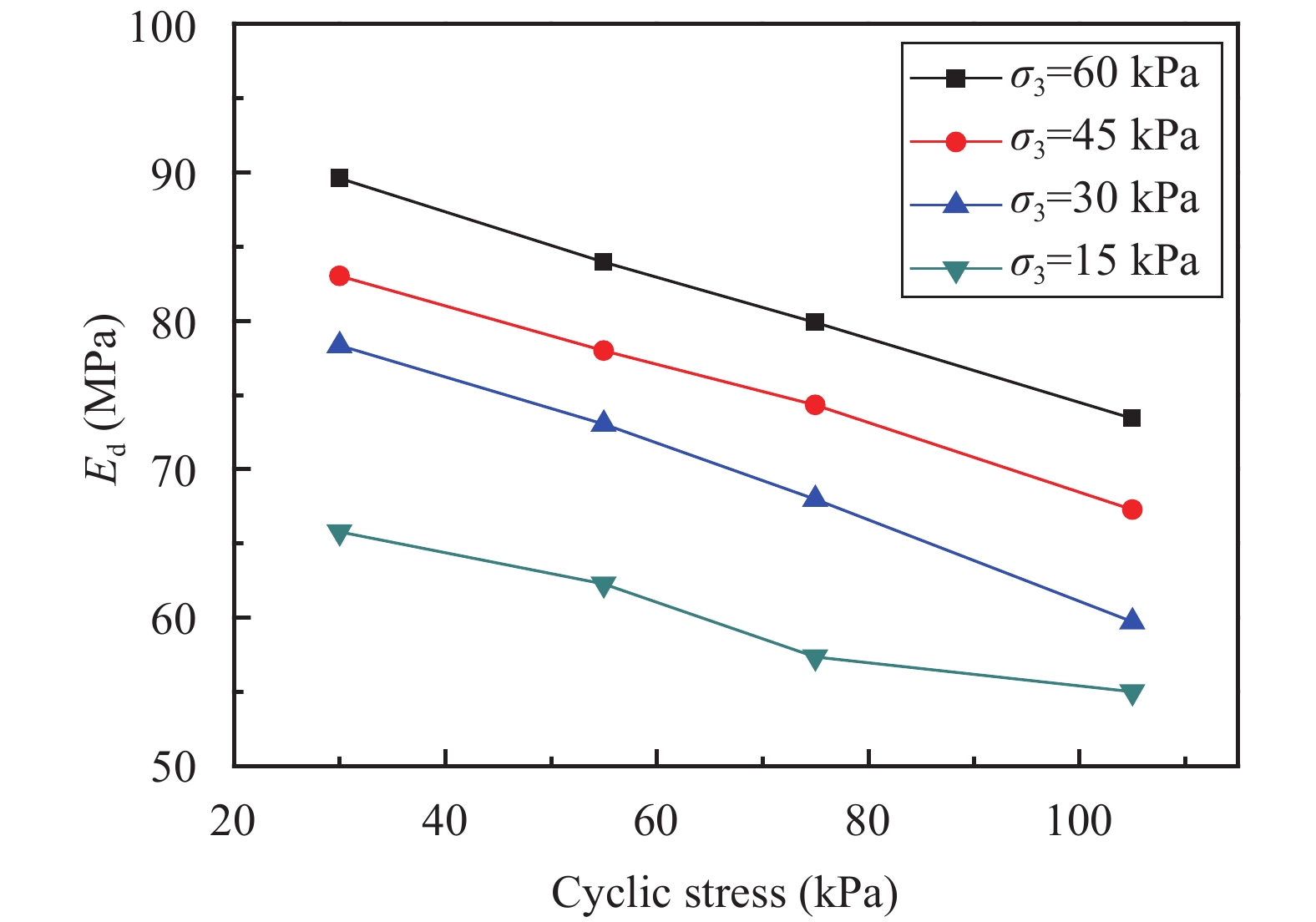

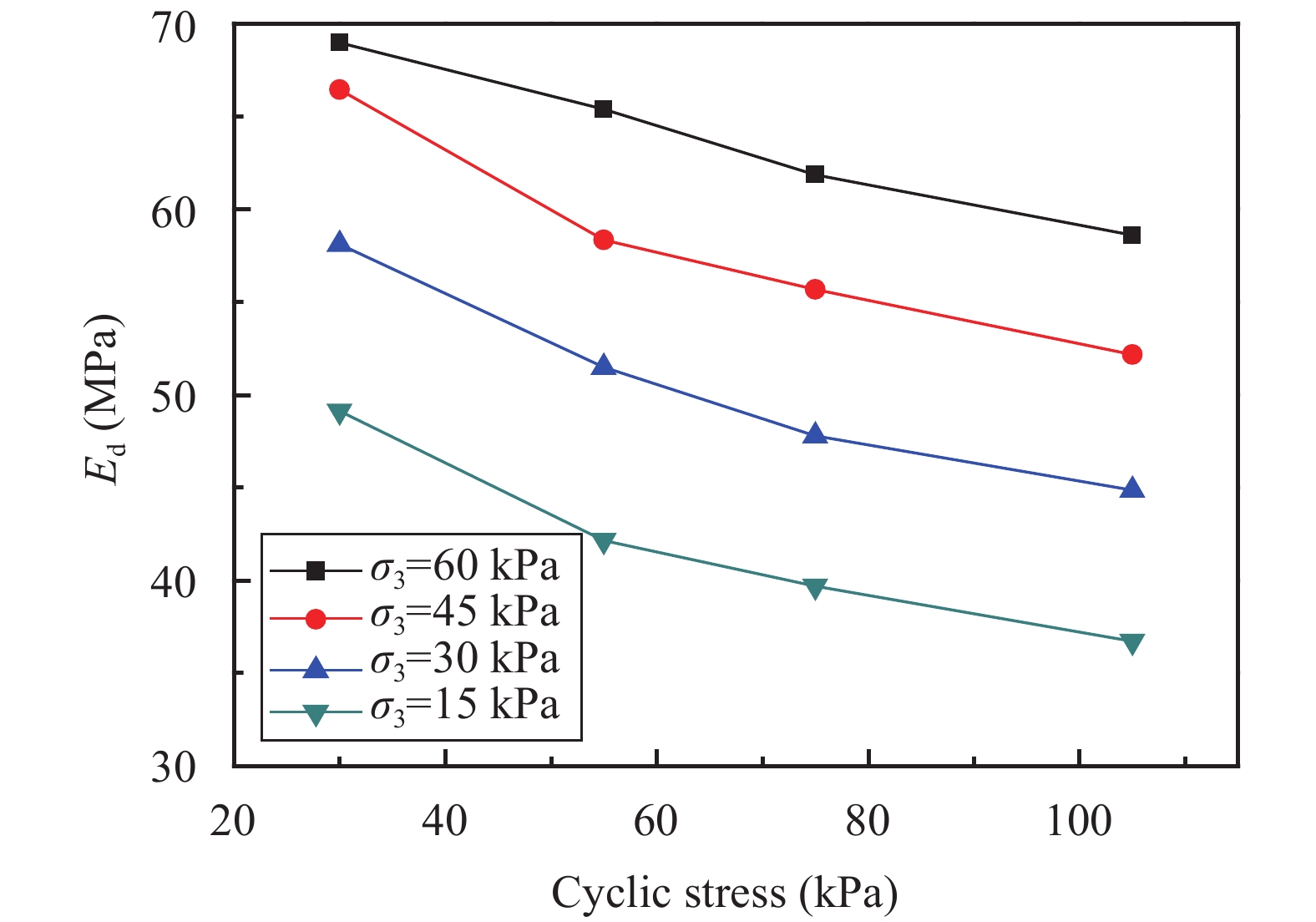

Figures 14~17 show the relation between dynamic resilient modulus and stress condition. As presented in Figures 14~17, the dynamic resilient modulus decreases with decreasing confining pressure. The dynamic resilient modulus decreases 0.2%~20.9%, 8.4%~36.8% and 20.0%~44.7% with the same cyclic stress and confining pressure decreasing from 60 to 45, 30, and 15 kPa.

|

| Figure 14 Dynamic resilient modulus at different confining pressure (Group 6) |

|

| Figure 15 The dynamic resilient modulus at different confining pressure (Group 8) |

|

| Figure 16 Dynamic resilient modulus at different confining pressure (Group 9) |

|

| Figure 17 Dynamic resilient modulus at different confining pressure (Group 14) |

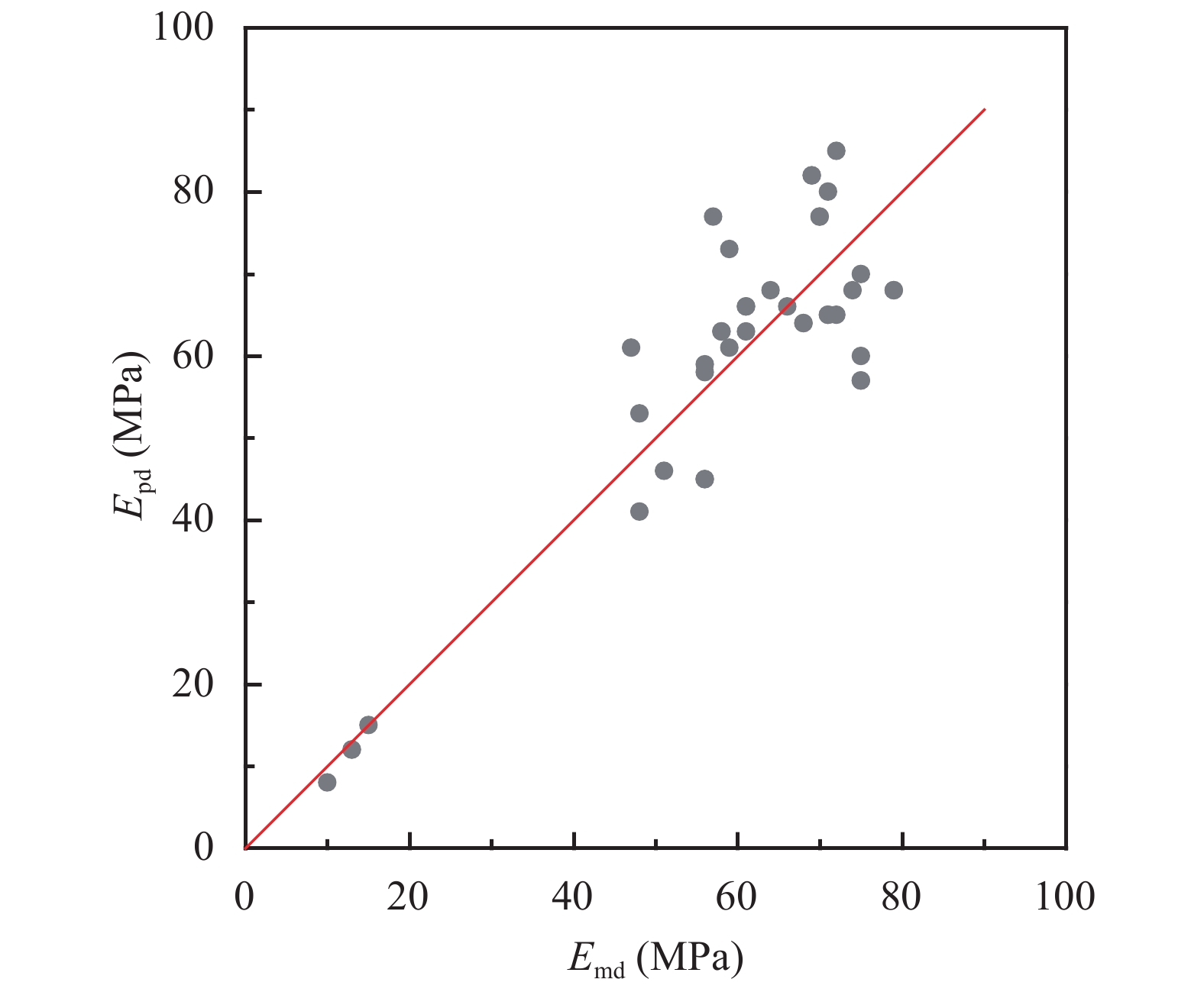

An empirical relationship between static and dynamic moduli was established under different water content, dry density and freeze-thaw cycles. The dynamic modulus of fine gained soil can be determined by static modulus from the following equation:

| $\begin{array}{l}{E_{\mathop{\rm d}\nolimits} } = {c_1}{E_s} + {c_2}{{\rm e}^{{k_1}}} + {c_3}{k_2} + {c_4}{k_3} + {c_5}\\[8pt]{k_1} = 0.00305\sigma - 0.016{{\rm e}^{\left( {T - 4} \right)}}\\[8pt]{k_2} = \displaystyle{\left( {\frac{w}{{{w_{best}}}}} \right)^4}\\[12pt]{k_3} = \displaystyle{{\rm e}^{\left( {\frac{\rho }{{{\rho _{\max }}}} - 0.36} \right)}}\end{array}$ | (4) |

where, Ed is the dynamic resilient modulus, Es is static resilient moduli, parameter c1=0.677, c2=30, c3=−15, c4=−14, c5=30. k1, k2, k3 are regression constants, which are related to the physical properties and status of the sample. The calculation method are as above, where σ is confining pressure, T is number of freeze-thaw cycles, w is water content, wbest is the optimal water content ratio, ρ is dry density, and ρmax is the maximum dry density,

5.2 Validation of the empirical modelIn order to verify the correctness of the model prediction, the results are compared with results presented in Figure 18. In this figure, Emd is measured dynamic moduli, and Epd is predicted dynamic moduli.

|

| Figure 18 Predicted versus measured dynamic resilient modulus |

As presented in Figure 18, the predicted results show a better agreement with experimental results. In most situations, the predicted dynamic resilient modulus is close to the measured dynamic resilient modulus, most errors are less than 15%. With the decreasing of confining pressure, the errors increase. When the confining pressure is 15 kPa, there is an error that more than 30%. Thus, Equation (4) can be used to estimate and predict the dynamic resilient modulus of fine soil considering water content, dry density, freeze-thaw cycle, and confining pressure (no less than 30 kPa) by its static resilient modulus. For a situation where confining pressure is less than 30 kPa, we would require further experiments to revise the equation.

6 ConclusionsIn the present study, a series of static and dynamic resilient tests were conducted subjected to different initial water content, dry density and closed-system freeze-thaw cycles. The static and dynamic resilient modulus versus different confining pressure and cyclic stress under different water content, dry density, number of freeze-thaw cycles were analyzed. The main conclusions can be drawn as follows:

(1) The static resilient modulus decreases 10.2%~40.0%, 14.4%~45.5%, and 24.0%~50.3% respectively with water content increasing from 16.5% to 23.1%, dry density decreasing from 1.70 g/cm3 to 1.56 g/cm3, and number of freeze-thaw increasing from 0 to 1, 3, 5, 7, and 10. The static resilient modulus becomes steady after seven freeze-thaw cycles, so the static resilient modulus after seven freeze-thaw cycles should be considered as the real static resilient modulus during the subgrade design.

(2) The dynamic resilient modulus decreases 10.9%~90.8%, 2.5%~38.4%, and 0.0~46.0% respectively with water content increasing from 16.5% to 23.1%, dry density decreasing from 1.70 g/cm3 to 1.56 g/cm3, and number of freeze-thaw increasing from 1 to 3, 5, and 7. The confining pressure plays a significant effect on dynamic resilient moduli. The dynamic moduli decrease about 0.2%~44.7% with confining pressure decreasing from 60 to 15 kPa.

(3) Considering the four presented factors, an empirical expression was formulated to estimate dynamic resilient modulus of fine soil based on the static resilient modulus. The empirical model can be used to predict the dynamic resilient modulus of fine soil subjected to water content, dry density, and freeze-thaw cycle.

Acknowledgments:We are thankful to personnel at the Key Laboratory of Highway Construction and Maintenance Technology, in seasonal frozen soil regions (Changchun), China. This research is supported by the National Key Basic Research Development Plan (2012CB026104), the National Natural Science Foundation of China (51408163, 51578200 and 41430634).

| Andrei D, Witczak MW, Schwartz CW, et al., 2004. Harmonized resilient modulus test method for unbound pavement materials. The 83rd Annual Meeting of Transportation Research Board, Washington D.C. DOI: 10.3141/1874-04. |

| Broms BB, 1964. Lateral resistance of piles in cohesive soils. Journal of the Soil Mechanics and Foundation Division, ASCE, 90(3): 123–156. |

| Brown SF, Hyde AFL, 1975. A significance of cyclic confining pressure in repeated-load triaxial testing of granular material. Transportation Research Record. Washington DC: TRB, pp. 49–58. |

| Chen SK, Ling JM, Zhang SZ, et al, 2006. Determination of loading sequence of subgrade dynamic resilient modulus indoor test. Highway, 11: 153–157. |

| Cole D, Bentley D, Durell G, et al., 1986. Resilient modulus of freeze-thaw affected granular soils for pavement design and evaluation, Part 1 Laboratory tests on soils from Winchendon, Massachusetts, test sections CRREL Report 86–4. |

| George KP, 2004. Prediction of resilient modulus from soil index properties. Mississippi: The University of Mississippi. |

| Graham J, Au VCS, 1985. Effects of freeze-thaw and softening on a natural clay at low stresses. Canadian Geotechnical Journal, 22(1): 69–78. DOI: 10.1139/t85-007 |

| Han YP, 2005. Resilient modulus estimation system. Ph.D. Dissertation, Missouri: University of Missouri-Rolla, 2005. |

| Hicks RG, Monismith CL, 1971. Factors influencing the resilient properties of granular material. Transportation Research Record. Washington DC: TRB, pp. 15–31. |

| Johnson TC, Cole DM, Chamberlain EJ, et al., 1979. Effect of freeze-thaw cycles on resilient properties of fine-grained soils. Engineering Geology, 13(1–4): 247–276. DOI: 10.1016/0013-7952(79) 90036-X. |

| Ling JM, Chen SK, Cao CW, et al, 2007. Analysis of influencing factors of resilient modulus of subgrade soil. Journal of Building Materials, 10(4): 446–451. |

| Ling JM, Su HC, Xie HC, et al, 2010. Experimental study on dynamic resilient modulus of subgrade soil. Chinese Journal of Underground Space and Engineering, 6(5): 919–925. |

| Liu WM, Li ZY, Dong C, et al, 2013. Study on prediction model of dynamic resilient modulus of cohesive subgrade soils considering under different moisture. Highway Engineering, 6: 6–9. |

| Mao XS, Wang WN, Hou ZJ, et al, 2009. Experimental research on resilient modulus of remolded soil based on water content and freeze-thaw cycles. Chinese Journal of Rock Machines and Engineering, 28: 3585–3590. |

| Muhanna AS, Rahman MS, Lambe PC, et al., 1999. Resilient modulus measurement of fine-grained subgrade soils. Transportation Research Record. Washington DC: TRB, pp. 3–12. DOI: 10.3141/1687-01. |

| Raad L, Zeid BA, 1990. Repeated load model for subgrade soils: model applications. Transportation Research Record. Washington DC: TRB, pp. 83–90. |

| Seed HB, Chan CK, Lee CE, et al., 1962. Resilient characteristics of subgrade soils and their relationship to fatigue failures in asphalt pavements. Proceeding International Conference on Structural Design of Asphalt Pavement. University of Michigan, pp. 611–636. |

| Simonsen E, Isacsson U, 2001. Soil behavior during freezing and thawing using variable and constant confining pressure triaxial tests. Canadian Geotechnical Journal, 38(4): 863–875. DOI: 10.1139/cgj-38-4-863 |

| Simonsen E, Janoo V, 2002. Resilient properties of unbound road materials during seasonal frost conditions. Journal of Cold Regions Engineering, 16: 28–50. DOI: 10.1061/(ASCE)0887-381X(2002)16:1(28) |

| Wang J, Lv X, Zhang YL, et al, 2016. Study on static and dynamic modulus relationship of subgrade soil in seasonal frost regions. Journal of Highway and Transportation Research and Development, 33(9): 25–30. |

| Yau A, Quintus HV, 2004. Predicting elastic response characteristic of unbound materials and soils. The 83rd Annual Meeting of Transportation Research Board, Washington D.C. DOI: 10.3141/1874-06. |

| Zhang SZ, 2008. Experimental study on dynamic modulus of subgrade soil. Northern Communications, 6: 18–21. |

2017, 9

2017, 9