Article Information

- QingZhi Wang, JianKun Liu, JianHong Fang, AnHua Xu . 2017.

- Direct shear tests of coarse-grained fillings from high-speed railway subgrade in cold regions

- Sciences in Cold and Arid Regions, 9(3): 236-242

- http://dx.doi.org/10.3724/SP.J.1226.2017.00236

Article History

- Received: November 21, 2016

- Accepted: December 21, 2016

2. Qinghai Research Institute of Transportation, Xining, Qinghai 810003, China

High-speed trains must meet stringent requirements with regard to speed, comfort, and safety, and therefore, in the design of high-speed railway subgrade, strength, stiffness and stability of fillings must be carefully considered. According to the 'Code for designs of the newly 200~250 km dedicated passenger railway line' in China, graded sand gravel and graded crushed rock were used as fillings in the surface layer of the subgrade; Group A, Group B or modified soils were used as fillings in the bottom surface layer of the subgrade. These fillings are considered coarse-grained soils, which have the advantages of low absorbance, low settlement deformation, low frost heave, high permeability, and high bearing capacity. The shear strength of these coarse-grained soils can be determined by a large-scale direct shear test or tri-axial shear test. The effects of particles, shape, density and moisture content on shear strength of coarse-grained soils have previously been studied in detail (Guo, 1998). Chen (1994) conducted tri-axial compression tests on coarse-grained soils and indicated that the failure surface was an irregular curve, not a plane, since the coarse particles in the shear surface blocked the shear process. The main strength source was the interlocking force, instead of the cohesion force, and thus the strength of the coarse-grained soil increased. Yang et al. (2010) studied the variation of shear strength indices of coarse-grained soils with different compactness and water-bearing states with direct shear and tri-axial compression tests. Their study reported that shear strength increased with increasing compactness and confining pressure, that the cohesion force significantly increased and that the inner friction angle did not significantly vary.

According to the China's Mid-to-Long Term Railway Network Plan (2008), a large number of High-speed Railways are currently being constructed in cold regions in China, and even more will be constructed in the future. The Harbin-Dalian HSR was constructed between August 2007 and December 2012 and is considered to be the first HSR that operates at high latitudes and low winter temperatures. The Shenyang-Dandong HSR, which began operation in September 2015, was also constructed for a region that has seasonally frozen soil. Thus, how freeze-thaw cycles and cold temperatures can impact the strength of coarse-grained fillings of HSR subgrade should be thoroughly investigated. However, there are few studies that report direct shear tests of coarse–grained fillings in cold regions. Ma and Wang (2014) confirmed that during the freezing of soil, in which pore water freezes due to cold temperatures and high pressures, the internal structure of soil, and thereby, its strength, changes. Accordingly, significant differences in strength were found between frozen and unfrozen soil, and the most important factors affecting the frozen soil strength were the pore ice characteristics and its bonding with soil particles. Wu et al. (1994) demonstrated that increasing the confining pressure significantly improved both plasticity and strain hardening properties of Lanzhou frozen sandy soil with tri-axial shear tests. Qi and Ma (2010) summarized the strength theories of frozen soil. Peng et al. (2007) studied the impacts of the degree of compaction and water content on the stress-strain curves, and on shear strength, cohesion force and internal friction angle of compacted silt from Beijing–Kowloon Railway subgrade. Liu et al. (2014) used silty clay taken from the Harbin–Dalian passenger line and conducted direct shear tests of frozen soil-concrete interface and proposed that the freezing strength of the soil was comprised of the freezing strength of ice-concrete and the cohesion among soil grains, unfrozen water and the concrete surface. Wen et al. (2013) performed direct shear tests of the interface between silt and fiberglass-reinforced plastic plates of frozen samples and reported that the interface strength drastically decreased when the load reached its critical strength and there was short or no significant strain hardening stage. Bu and Wang (2015) analyzed the influence of freeze-thaw cycles, fine particle content and confining pressure on the shear strength properties of coarse-grained soil. With increasing fine particle content, the stress-strain curve displayed a change from strain-softening before the freeze-thaw cycles to strain-hardening after freeze-thaw cycles.

These studies reflect that it is necessary to study the shear strength variation of coarse-grained fillings of HSR subgrade in cold regions under different conditions. In this study, large scale direct shear tests were conducted with Group A soil taken from a HSR subgrade bottom layer located in northeastern China. The shear behaviors of these fillings were analyzed at different water contents and temperatures. The shear strength, cohesion and interlocking force, internal friction angle and shear dilation characteristics were analyzed in detail.

2 Test apparatus and test methodThe large scale temperature-controlled direct shear test system (TZJ-150) in a frozen soil laboratory of Beijing Jiaotong University was used for these tests (Figure 1). The shear test system is a large scale computerized numerical controlled direct shear apparatus with a built-in cooling bath circulation device. Vertical and horizontal pressures were driven by two stepper servo motors with maximum outputs of 100 kN and 150 kN. With a feedback control module on each motor, displacement and pressure in both directions were precisely controlled. The box with a volume of 300mm×300mm×180mm had a steel structure inside and a space for cold liquid outside, covered with layers of insulation. A cooling bath circulator was connected to the shear box to control the cooling process. A constant vertical temperature gradient was kept near the shear interface.

The Shenyang–Dandong HSR, which was built for speeds of up to 250 km/h, connects to the Beijing–Shenyang HSR and the Harbin–Dalian HSR, both of which are located in northeastern China. According to observations, this area is characterized by a continental climate of a northern temperature zone and has annual mean temperature of 7.4 °C and annual precipitation of 821 mm. Winter in this region extends from November to March, and over the past 50 years, from 1960 to 2010, the average minimum winter temperature is −10.3 °C. The spring thaw period ranges from March to April and has a mean temperature of 8.1 °C.

|

| Figure 1 Structure of the large direct shear apparatus |

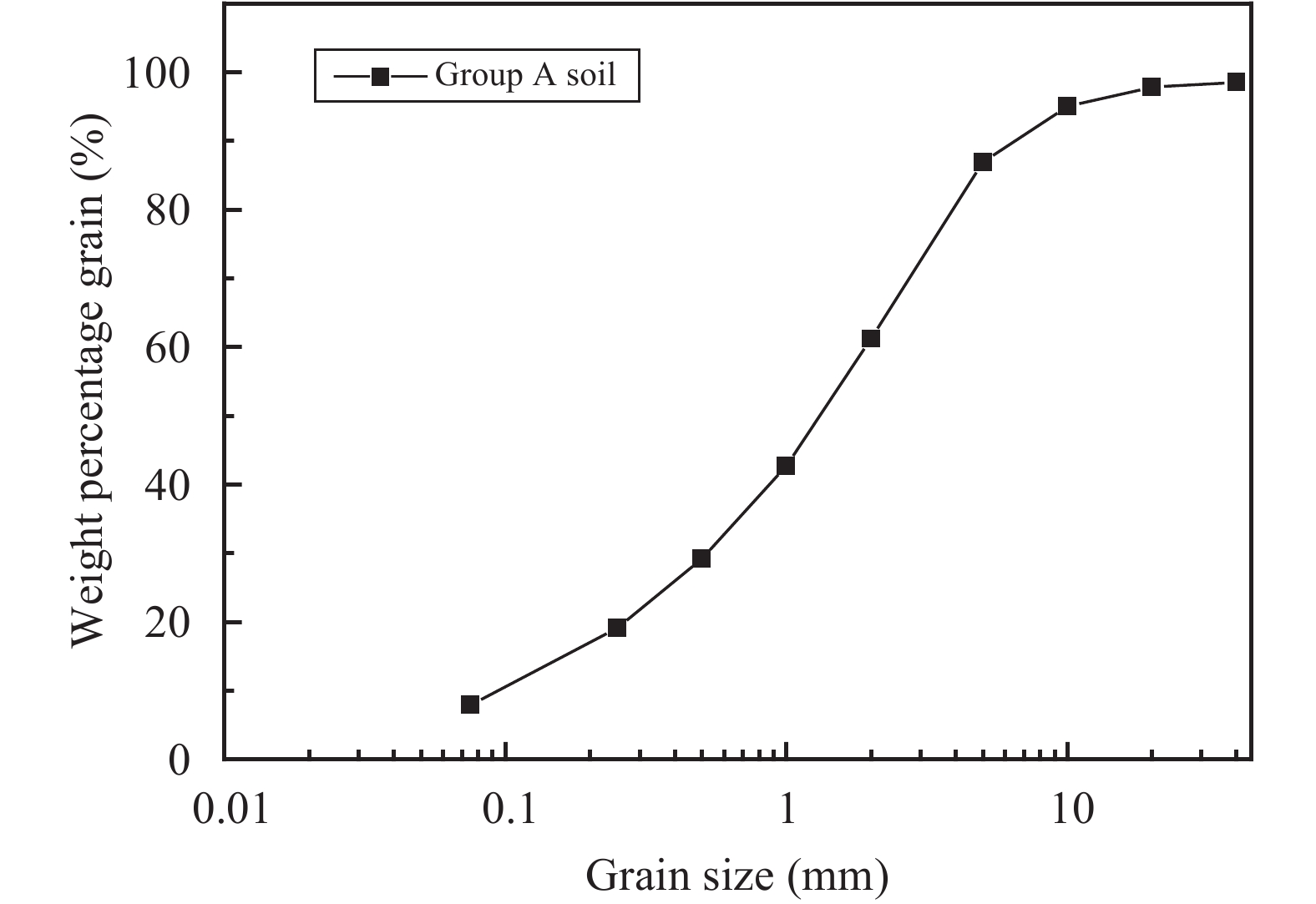

The coarse-grained fillings were taken from the Shenyang–Dandong HSR subgrade bottom layer, Group A soil, determined by the 'Code for Railway Subgrade Design' (TB10001-2005). This soil is fine gravel of round particles with little edges and corners. The grain size of coarse-grained fillings is presented in Figure 2. The optimal water content and maximum dry density of the coarse-grained fillings are 7%, and 2.2 g/cm3, respectively.

The sample in the shear test was compacted with three layers using the vertical loading module to achieve the desired compactness. The vertical loading module was used to provide a steady normal pressure, and the horizontal module was activated to push the shear box with a speed of approximately 10 mm/h. The data collector recorded the stresses and displacements in both directions with a sampling frequency of 50 Hz. During the whole shear process, feedback control helped achieve a constant normal pressure, with an error of 2 kPa.

|

| Figure 2 Grain size of coarse-grained filling |

When the test was conducted in freezing conditions, a series of temperature sensors were placed in the shear box, inside the soil and near the shear surface, and a DT 80 was used to monitor temperatures. Then, the cooling bath circulation was started to ensure that the temperatures in the soil and on the shear surface were equal, indicating that the sample reached a thermal balance and the temperature field was stable (usually took 18~24 hours). When the test was finished, the cooling bath was stopped and the sample was left to thaw, as presented in Figure 3. During the entire shear process in the frozen state, the cooling bath circulation automatically adjusted the temperature with variations less than 1.0 °C according to temperature sensors inside the sample. Samples near the shear surface were selected to determine the average water content after the freezing process. The water content variation of Group A soil was less than 1%. Therefore, the temperature and water content near the shear failure surface was assumed to be constant.

In order to study the shear behavior of coarse-grained fillings of HSR subgrade in cold regions under different conditions, large scale direct shear tests were conducted with Group A soil in frozen or unfrozen states, and thus different water contents, temperatures and normal pressures were evaluated, as presented in Table 1.

|

| Figure 3 The sample of the direct shear test |

| Soil | Compactness | NP | WC (%) | T (°C) |

| Group A soil | 0.95 | 50, 100, 150, 200, 300, 400 | 7 | 20 |

| −1 | ||||

| −3 | ||||

| −5 | ||||

| 9 | 20 | |||

| −1 | ||||

| −3 | ||||

| −5 | ||||

| 12 | 20 | |||

| −1 | ||||

| −3 | ||||

| −5 | ||||

| Note: NP refers to normal pressure (kPa), WC refers to water content (%), T refers to temperature (°C). | ||||

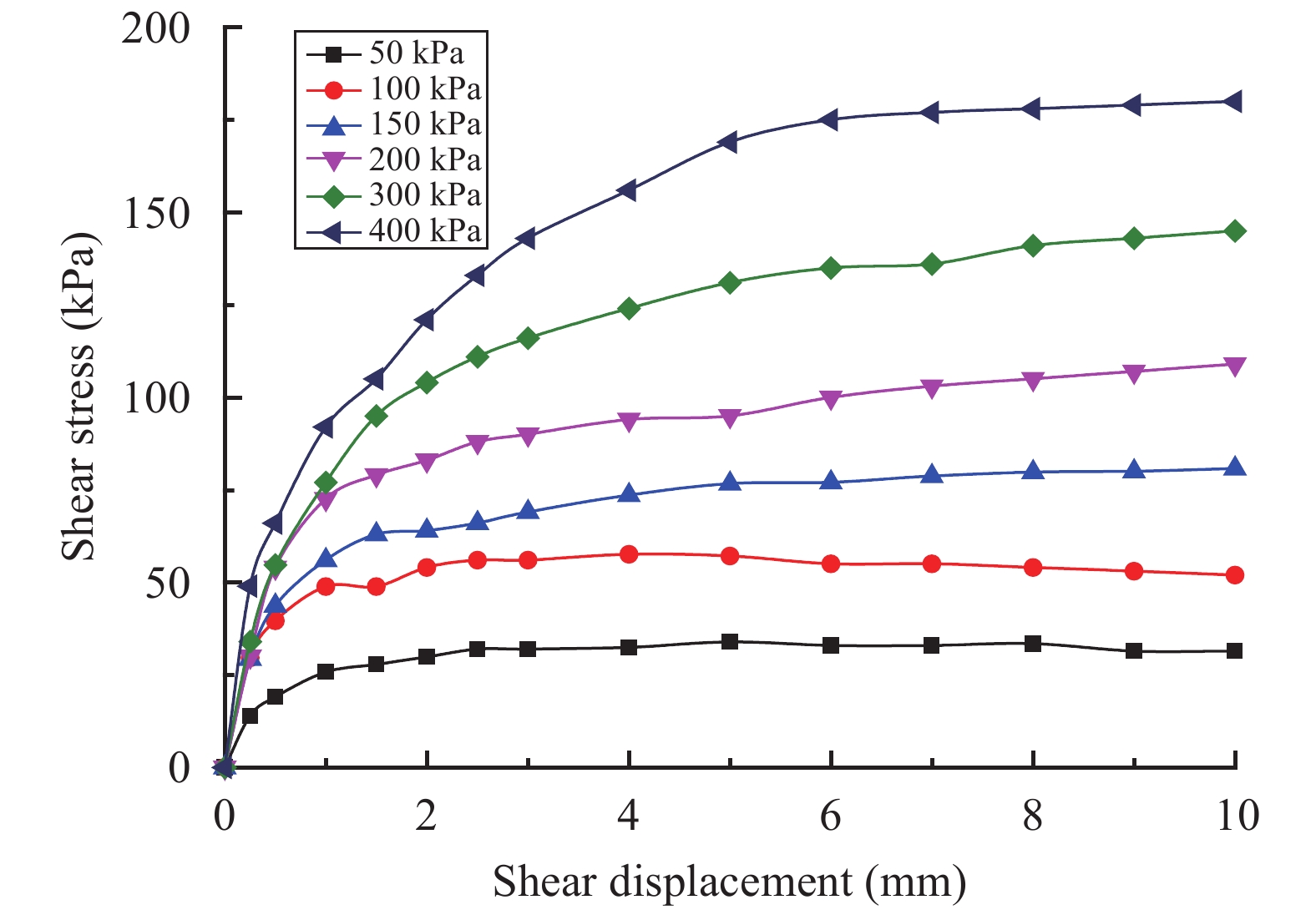

The shear displacement-shear stress curves of coarse fillings with different normal pressures at a temperature of 20 °C (unfrozen state) are presented in Figure 4. Group A soil had 0.95 compactness and 9% water content. The relationship between shear displacement and shear stress can be characterized by the following stages. During the initial stage of the shear process, shear stress linearly increased with increased displacement and was dominated by the elastic deformation of soil. When the shear displacement reached a certain value, shear stress increased nonlinearly and plastic deformation began. Then, there was a sudden decline in the average shear stress, cracking sounds appeared during the tests, and the sample began slide failure. Finally, the shear stress declined or was steady at a stable magnitude.

|

| Figure 4 Shear displacement-shear stress curves of unfrozen coarse fillings (temperature 20 °C, water content 9%) |

At different normal pressures, shear stress values were different when the shear displacement reached a certain value. Shear stress increased with increasing normal pressure. When the sample was undergoing slide failure, the shear displacement and shear stress also increased with increasing normal pressure. The stress-displacement curve, at first, displayed strain-softening behavior with an obvious peak in shear strength, but then displayed strain-hardening and did not have an obvious shear strength peak. This transition was mainly due to the structure properties and shear dilatation characteristics of the coarse-grained fillings. Coarse-grained fillings are composed of different sizes and granular structure properties, and when the sample is compacted, particles fill into the interspace. Unlike fine-grained soils, the shear strength of coarse-grained soil is mostly dependent on the force of friction and the interlocking force. When normal pressure was applied during the shear process, with high compaction, different size particles are squeezed more and more tightly. With large friction and interlocking forces, particles moved across the shear failure surface or shear failure zone, even passing over nearby particles, and the shear dilatation deformations appeared. The work increased due to overcoming the shear dilatation deformation and led to increasing shear stress. Shear stress increased until it reached a maximum, at which point the sample approached the stage of whole slide failure. After slide failure, due to shear dilatation deformation, the packing of the coarse-grained filling became loose and the interlocking force gradually decreased, eventually to zero. Therefore, the shear stress decreased and this is the reason why strain-softening was observed in the shear tests of Group A soil at lower normal pressures, though not very significantly. When the larger normal pressures were applied, there was a greater force of resistance that hindered particle movement, which then led to less shear dilatation deformation. In the relationship between shear displacement and shear stress, these larger normal pressures resulted in a transition from strain-softening to strain-hardening. It is also why that highly compacted coarse-grained fillings, in addition to overcoming the friction force, the work of overcoming the shear dilatation deformation was greater in the highly compacted sample during the shear process, had a greater strength than a less compacted one.

The transition from strain-softening to strain-hardening in the relationship between shear displacement and shear stress was verified experimentally. The shear displacement and normal displacement were recorded during the shear process of unfrozen Group A soil under different normal pressures. Due to the high degree of compaction, the sample displayed different degrees of shear dilatation deformation during the shear test. With lower normal pressures, a greater shear dilatation deformation appeared, and with increasing normal pressure, the dilatancy effect decreased. Shear contraction did not appear in shear tests of the coarse-grained fillings.

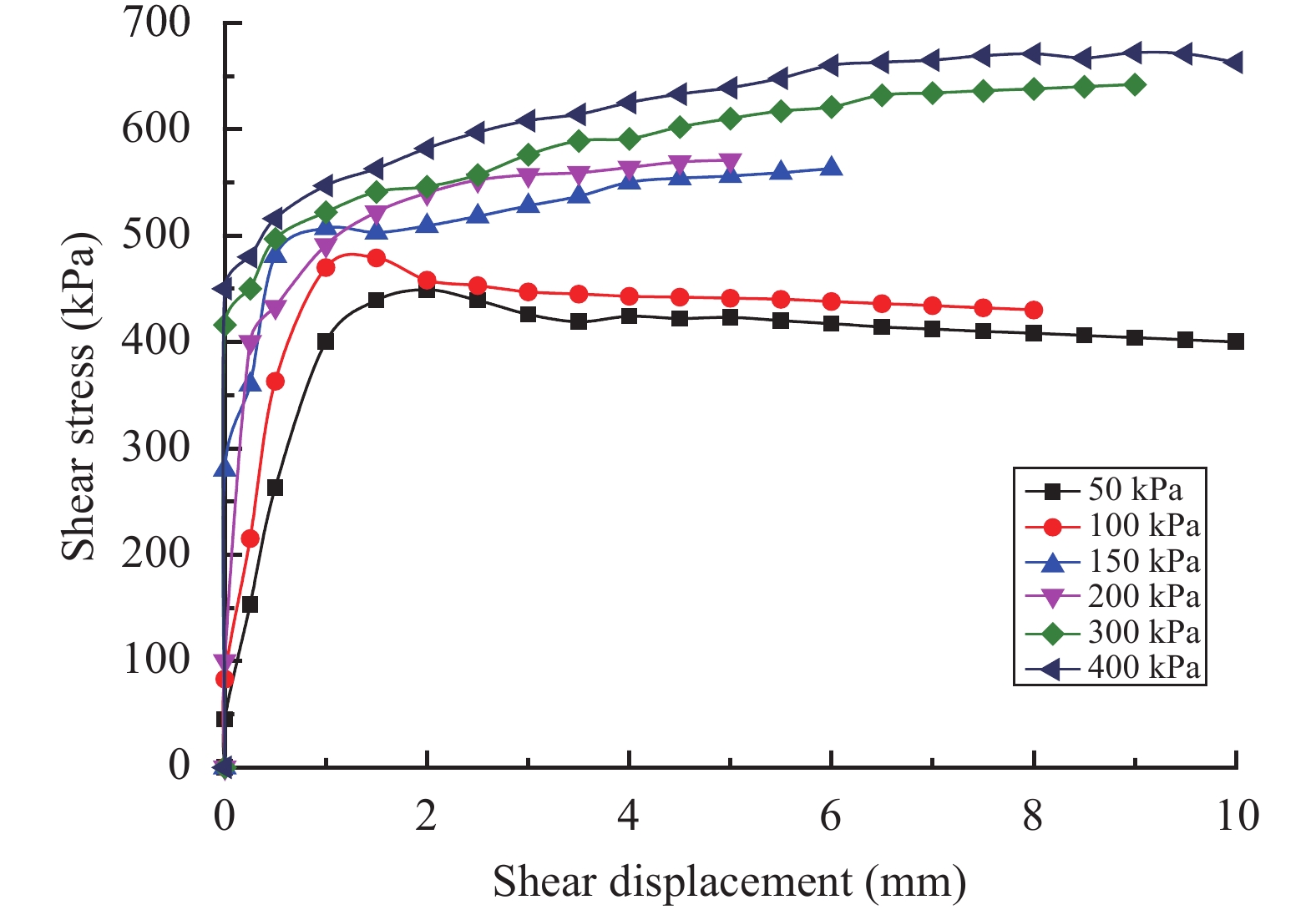

3.2 Shear displacement and shear stress characteristics of frozen coarse-grained fillingsThe shear displacement-shear stress curves of the coarse fillings under different normal pressures are presented in Figure 5. The frozen state temperatures were −3 °C for Group A soil that had 0.95 compactness and 9% water content. Unlike in the unfrozen state, the shear stress rapidly increased and there was not an increment in the shear displacement during the initial stage of the shear process. For example, the elastic deformation in the frozen state was not as obvious as in the unfrozen state. However, other stages of the shear displacement and shear stress relationship were similar to those in the unfrozen state. Similarly, as can be seen from Figure 5, the shear displacement and shear stress curve displayed strain-softening at lower normal pressures, not very significantly, but strain-hardening at higher normal pressures. With increasing normal pressure, the shear displacement and shear stress of Group A sample finally reached the stage of whole slide failure. However, compared to the unfrozen state, the shear displacement was smaller in the frozen state.

|

| Figure 5 Shear displacement-shear stress curves of frozen coarse fillings (temperature −3 °C, water content 9%) |

The shear strength of coarse-grained fillings was due to fine particles strength, coarse particles strength and the cohesion and interlocking force between fine and coarse particles. According to the definition by Guo (1998), the Coulomb equation was used to determine the shear strength characteristics of coarse-grained fillings.

Peak shear strength, the highest point before shear stress release in the shear displacement and shear stress curve, is the maximum shear stress experienced before the sample breaks. For example, in the strain-softening region for unfrozen Group A soil, the peak shear strength value was 33.84 kPa at 50 kPa normal pressure and 58.34 kPa at 100 kPa normal pressure. If there was not an obvious shear stress release, the shear strength could be determined from the strain-hardening region when the sample reached the stage of whole slide failure. For example, in the unfrozen state, the shear displacement range varied from 4 mm to 8 mm (strain of 1.33%~2.67% for scale of 300 mm transverse dimension) and the shear stress of an average displacement of 6 mm (strain of 2% for scale of 300 mm transverse dimension) was considered the peak shear strength (Figure 4). When shear displacement reached 3 mm (strain of 2% for scale of 300 mm transverse dimension) in the frozen state, the shear stress was considered the peak shear strength (Figure 5).

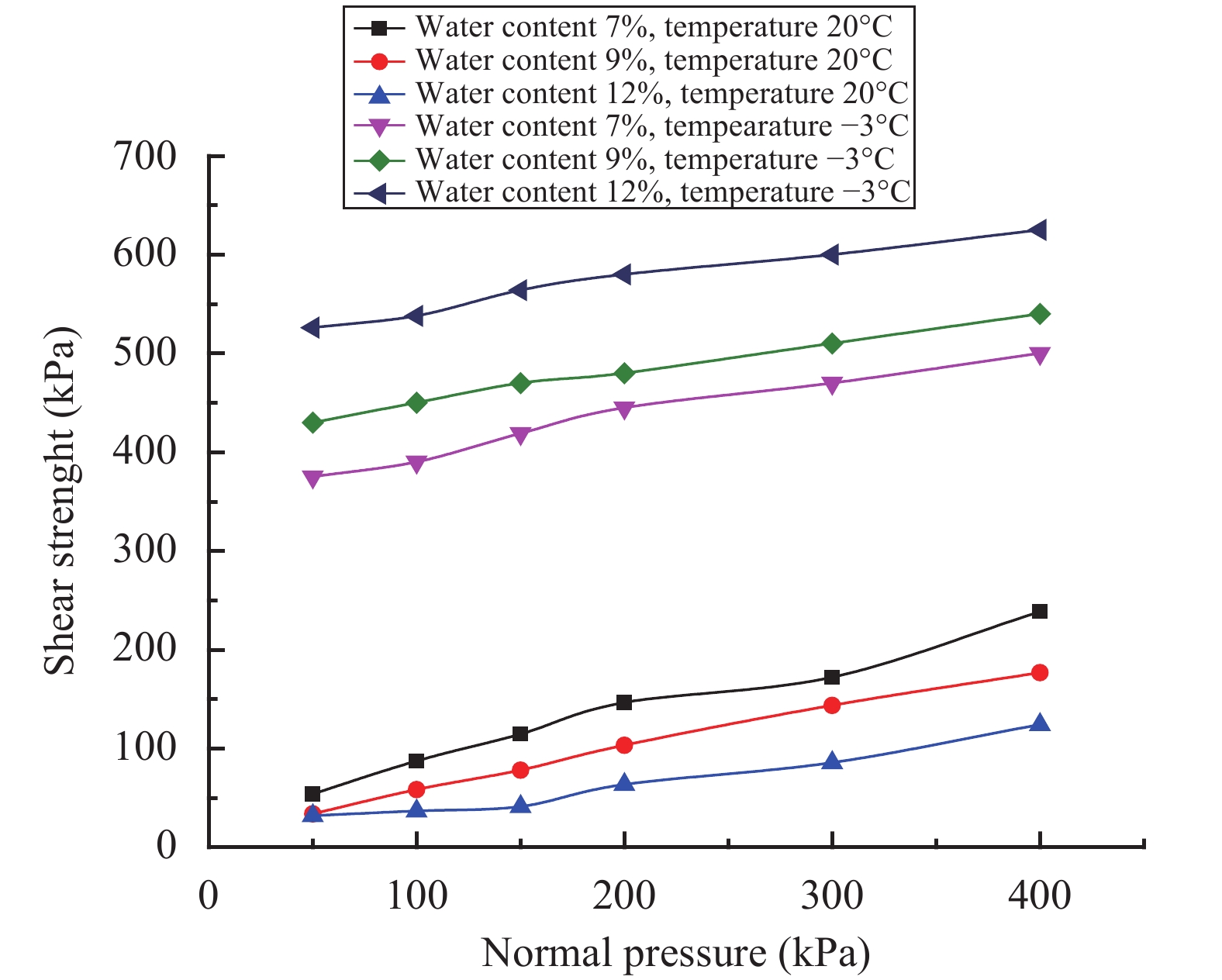

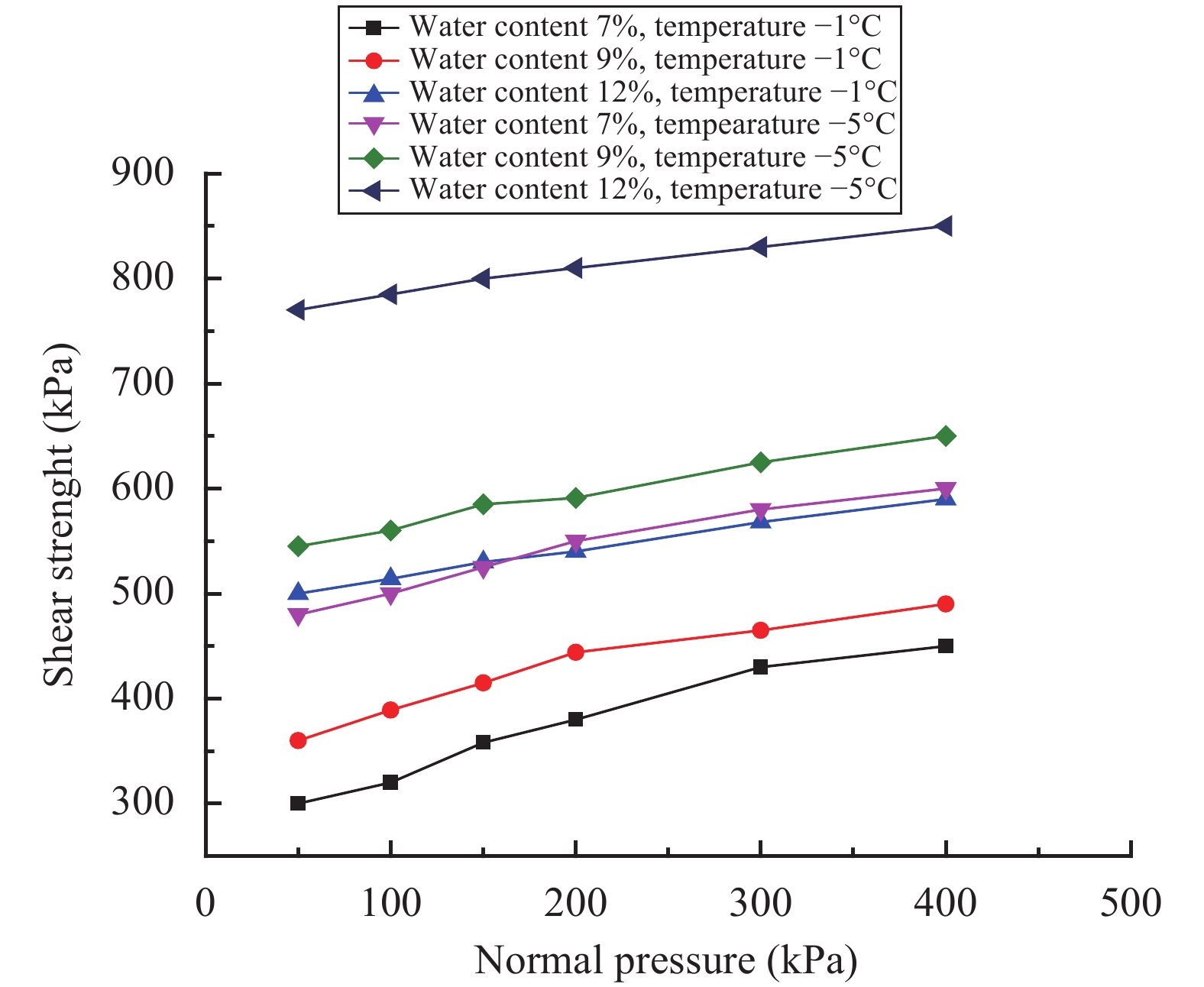

The variations of shear strength of coarse-grained fillings with different normal pressures in unfrozen and frozen states are presented in Figure 6. When the water content was constant and temperature was 20 °C, the shear strength of Group A soil increased with increasing normal pressure. This result indicated that different size particles filled into the interspace more and more closely and the interlocking force greatly increased. The work to overcome the force of friction between particles also greatly increased. At the same normal pressure, the shear strength decreased when the water content increased from 7% to 12%, for example, when the normal pressure was 400 kPa, the shear strength decreased from 238.38 kPa (water content 7%) to 172 kPa (water content 12%). The increase in water content softened the soil and enlarged the distance between particles, resulting in a decrease in the ability to resist shear stress and lower shear strength. When the water content was constant and temperature was −3 °C (frozen), the shear strength of Group A soil showed the same increasing trend as the unfrozen. When the same normal pressure was applied, shear strength increased with increasing water content as indicated by the increase in the ability to resist shear deformation. The increase in shear strength was mainly due to the increase in the water content. More water was frozen during freezing and therefore, there were stronger bonding forces between the ice and soil particles, resulting in greater shear strength. For example, the shear strength increased from 375 kPa to 535 kPa when the water content increased from 7% to 12% at a normal pressure of 50 kPa and temperature of −3 °C. As presented in Figure 7, when the water content and normal pressure were kept constant, shear strength increased when the temperature was decreased from −1 °C to −5 °C. With lower temperatures, less liquid water in the fillings meant that there was a higher ice strength and stronger interaction between the ice and particles, which led to greater shear strength. For example, the shear strength increased from 360 kPa to 545 kPa when the temperature decreased from −1 °C to −5 °C at a normal pressure of 50 kPa and water content of 9%.

|

| Figure 6 Comparison of shear strengths of coarse fillings in unfrozen and frozen states |

|

| Figure 7 Comparison of shear strengths of coarse fillings with different water content and temperature |

As presented in Figures 6 and 7, the difference between shear strength was smaller with different water contents at the same normal pressure and when the temperature was 20 °C. However, the difference increased when temperature was −3 °C since ice formed among the particles and could bear a certain stress, leading to higher shear strength.

4 ConclusionsThis study describes the shear behavior of coarse-grained fillings in unfrozen and frozen states with large scale direct shear tests. From the highly precise and continuous recording of displacement and stress data, many details of the whole shear process were observed. Shear stress-shear displacement curves and shear strength were analyzed with varying normal pressures, water contents and temperatures.

Through analyses of the relationship between shear displacement and shear stress, we found that curves of highly compacted coarse-grained fillings changed from strain-softening at lower normal pressures to strain-hardening at higher normal pressures, in both unfrozen and frozen states. This phenomenon was mainly due to the shear dilatation deformation effect. With lower normal pressures, there was greater shear dilatation deformation, and when the larger normal pressures were applied, there was a smaller shear dilatation deformation.

Apparently, the magnitude of the freezing strength of coarse-grained fillings was due to the freezing strength of pore ice, the strength of fine and coarse particles, the interlocking force between fine-grained and coarse-grained particles, and the cohesion force between the soil grains, liquid water and the failure surface. In both the unfrozen or frozen states at the same water contents, the shear strength increased with increasing normal pressure. The shear strength of the coarse-grained fillings slowly decreased with increasing water content for the unfrozen sample. The strength of the frozen sample increased with decreasing temperature and increasing water content. With decreasing temperature, there was less liquid water, higher ice strength and therefore, stronger interactions between the ice and particles led to an increase in shear strength.

Acknowledgments:This research is supported by the National Natural Science Foundation of China (No. 51378057).

| Bu JQ, Wang TL, 2015. Influences of freeze-thaw and fines content on mechanical properties of coarse-grained soil. Chinese Journal of Geotechnical Engineering, 37(4): 608–614. DOI: 10.11779/CJGE201504005 |

| Chen XZ, 1994. Research on the strength of the coarse grained soil and the interlocking force. Engineering Mechanics, 11(4): 56–63. |

| Guo QG, 1998. Engineering Properties and Application of Coarse-Grained Soils. Zhengzhou: The Yellow River Conservancy Press. |

| Liu JK, Lv P, Cui YH, et al, 2014. Experimental study on direct shear behavior of frozen soil-concrete interface. Cold Regions Science and Technology, 104–105: 1–6. DOI: 10.1016/j.coldregions.2014.04.007 |

| Ma W, Wang DY, 2014. Mechanical Properties of Frozen Soils. Beijing: Science Press. |

| Peng LY, Liu JK, Xiao JH, 2007. Mechanics properties of compacted silt on Beijing-Kowloon Railway. Journal of Beijing Jiaotong University, 31(4): 56–60. DOI: 10.3969/j.issn.1673-0291.2007.04.014 |

| Qi JL, Ma W, 2010. State-of-art of research on mechanical properties of frozen soils. Rock and Soil Mechanics, 31(1): 133–143. DOI: 10.3969/j.issn.1000-7598.2010.01.025 |

| Wen Z, Yu QH, Ma W, et al, 2013. Direct shear tests for mechanical characteristics of interface between Qinghai-Tibetan silt and fiberglass reinforced plastics. Rock and Soil Mechanics, 34(S2): 45–50. |

| Wu ZW, Ma W, Zhang CQ, et al, 1994. Strength characteristics of frozen sandy soil. Journal of Glaciology and Geocryology, 16(1): 15–20. |

| Yang Y, Luo Q, Chen Z, 2010. Experimental study on shear strength of graded gravel for passenger dedicated line. Subgrade Engineering, 4: 75–78. |

2017, 9

2017, 9