Article Information

- DaYan Wang, Wei Ma, LeLe Lei . 2017.

- Study on the freezing-thawing deformation of consolidated soils under high pressure

- Sciences in Cold and Arid Regions, 9(1): 29-37

- http://dx.doi.org/10.3724/SP.J.1226.2017.00029

Article History

- Received: June 13, 2016

- Accepted: October 21, 2016

With the world's growing demand for energy and living space, underground engineering constructions, such as underground mine, underground railway, underground power station, are becoming a developing tendency in engineering development. However, determining how to excavate the deeper underground space is challenging for the progress as well as the cost of such projects. Sometimes, it even determines the success or failure of an engineering construction. At present, of all the construction methods used for underground excavation, artificial ground-freezing technology is becoming an extensively used method, for its characteristics of adaptability, flexibility, strong controllability, impermeability, and environmental protection (Jessberger, 1980). Especially for deep mines, no better method has yet been established for sinking production shafts through deep, water-bearing ground (Harris, 1995; Cui, 1998; Andersland and Ladanyi, 2003). Here, the so-called artificial ground freezing is a method to convert the in situ pore-water into ice to form a bonding agent, fusing together adjacent particles of soil or blocks of rock to create a frozen soil mass with markedly improved compressive strength and impermeability. The frozen wall is also referred to as a temporary support, which will be removed by thawing after the construction work is completed (Andersland and Ladanyi, 2003).

In the application of artificial ground freezing technology, the frozen soil's physical-mechanical properties have to be considered seriously since these characteristic determine the frozen wall's design and strength, and the surrounding buildings' stability. For example, the frozen soil strength under different temperature determines the frozen wall's thickness; the soil's freezing-thawing process corresponds to the amount of freezing-thawing deformation, which has great influence on the surrounding buildings' stability. However, in the case of current engineering construction, the presented frozen soil physical-mechanical theory obtained from cold-regions engineering can be used for designing only a frozen wall located in a shallow stratum. If these theories are applied to designing a deeper frozen wall (in 50 m or much a deeper stratum), there will be some unintentional effects, such as excessive radial deformation or fracture in the frozen wall, the splitting of the freezing pipes, and so on (Ma et al., 1979; Yang et al., 1996; Yang et al., 1999). These had already been proved by some engineering accidents in regions of Huabei, Yanzhou, and Datong, where mineral resources lay under thick alluvium, and the artificial ground-freezing technology was applied to extract them (Huang et al., 1997; Lu et al., 1997; Ma and Wang, 2012).

Carefully analyzing the causes of these occurrences, researchers understand that for the soils lying in deep a stratum, the action of the ground pressure could not be neglected because it changes the mechanical properties of a frozen wall by changing the process by which the frozen wall forms, as well as the moisture distribution characteristics and the loading path. Available research results indicate that the initial freezing temperature of a deep stratum is usually lower than that of the shallow stratums, due to the high ground pressure (Chamberlain et al., 1972; Alkire et al., 1973). This finding means that, for soils under the same water content and temperature conditions, the unfrozen moisture content of a frozen wall in a deep stratum is higher than that in a shallow stratum. In addition, under high pressure, the distribution and immigration of the pore-moisture differs from that of the shallow stratum with low pressure or without pressure. Li et al. (1993) suggested that these abovementioned factors must give rise to changes of the frozen wall strength. Hence, since the early 1990s, some researchers have turned their attention to investigating the mechanical properties of deep, artificial frozen soils. Starting by developing laboratory testing systems, they have performed laboratory experiments to analyze deep, frozen soils' elastic deformation range and influencing factors, to determine the stress-strain behavior of deep, frozen soils and, further, to find a way for predicting shear strength (Ma et al., 1999, 2000; Ma and Chang, 2002; Wang et al., 2004, 2008). However, due to a poor understanding of the soil's freezing-thawing process under high pressure, the problems about how to predict the ground surface deformation in the process of freezing-thawing has not yet been resolved, which also limits us to further study the mechanical properties of the deep, frozen soils (Ma and Wang, 2012).

In view of this, a series of freezing-thawing process tests for sand and loess were undertaken to study the combined effect of high overburdening pressure, the frozen soils' temperature, and the soil type on the freezing-thawing deformation. To simulate in the laboratory the natural formation process of deep stratums, the sand or loess samples should be subjected to a K0-consolidation process before dropping their temperature to a desired negative temperature. The data are analyzed to provide a reference for precisely estimating the maximum deformation in the frozen-wall formation process. The aim is to prevent accidents and to avoid unnecessary conservatism in choosing artificial ground-freezing technology to reinforce soils in deep alluvium, and to result in substantial construction savings.

2 Materials and methods 2.1 Sample preparationThe soil used in this study was loess and sand obtained from Lanzhou, in Northwest China. Their main characteristics are presented in Table 1. Cylindrical samples nominally 61.8 mm in diameter and 125 mm in length were prepared by packing a split copper mold. The water content and the dry unit weight of the loess samples tested are 16.5% and 1.78 g/cm3, and that of the sand samples tested are 10.5% and 2.0 g/cm3, respectively.

| Soil type | Composition of grains (%) | Liquid limit (%) | Plastic limit (%) | Dry unit weight (g/cm3) | Moisture content (%) | |||

| Sands | >0.5 mm | 0.5~0.05 mm | 0.05~0.005 mm | <0.005 mm | ||||

| 25.6 | 54.23 | 8.04 | 12.13 | 2.0 | 10.5 | |||

| Loess | >0.1 mm | 0.1~0.05 mm | 0.05~0.005 mm | <0.005 mm | ||||

| 1.7 | 5.4 | 58.6 | 34.3 | 24.6 | 17.7 | 1.78 | 16.5 | |

The tests were carried out in a high-pressure-low-temperature (HPLT) K0 consolidation apparatus with microcomputer control and logging facilities, which was designed by State Key Laboratory of Frozen Soil Engineering of China (SKLFSEC) and further developed by Ma and Chang (2002). As the apparatus has both the function of conducting a conventional frozen-soil triaxial test and the soil K0 consolidation process, it is possible for us to simulate the process of forming deep, artificially frozen soil in the laboratory. In this experiment, the MTS-810 triaxial testing machine was still used as a loading system, as it has an ability to control the confining pressure and the axial pressure simultaneously. Generally, the maximum axial force is 20 t; and the maximum confining pressures is 40 MPa. During the experiments, the axial deformation was automatically measured by the axial pressure system, and the data were continuously collected by computer. The temperature control system was composed of the cell temperature transducers, the cold-bath circulation system, and the thermal insulation system. In this apparatus, to monitor the sample temperature variation more precisely, the temperature transducers were buried into the tested samples through a hole located in the loading pole, instead of putting the temperature sensor on the side wall of the sample. The cold-bath circulation system was used for adjusting the oil temperature in the cell to control the tested sample's temperature. The thermal insulation system mainly refers to the thermal insulation layer of polyurethane foam, whose role is to reduce the heat exchange between the interior cell and the external environment, and to keep the cell temperature consistent throughout testing process. According to the calibration results, temperature control precision is within 0.5 ℃.

This HPLT K0 consolidation cell has the ability to bear pressures up to 20 MPa and to drop the temperature to -60℃. In addition, a drainage system was designed at the bottom platen to drain the soil moisture in the consolidation process, and a pore-water-pressure transducer was set to monitor the pore-water-pressure dissipation process. By regulating stress and strain rates simultaneously, the HPLT K0 consolidation apparatus can simulate the incremental process of overburdening pressure, recreate the loading history, and restore the tested soils to the initial stress states found in the field. By regulating the temperature of the cold bath circulating around the sample cell, the sample temperature could be controlled and the freezing-thawing process experiment could also be conducted under a higher pressure.

The detailed experimental procedure basically consists of three parts:

1) K0 consolidation stage. This process restores the tested soil sample to its original state in the deep alluvium. To maintain the specimen without lateral deformation during its consolidating process, the static lateral pressure coefficient K0 of the tested soils should be firstly determined. Then, given the loading rate of the confining pressure σ3, the loading rate of axial pressure σ1 was determined by the formula σ1=σ3/K0. After that, the prepared sample was wrapped with a flexible latex membrane and placed on a pedestal within the HPLT K0 consolidation apparatus. Finally, the axial pressure and the confining pressure were loaded simultaneously. In the process of loading, to ensure σ1 and σ3 reached the desired confining stress at the same time, the consolidating pressures were controlled at a rate of calculated results, shown in Table 2. When the specified magnitude of confining stress σ3 was reached, the load was kept constant until the axial strain rate was less than 0.01% per hour; and then the drainage valves were closed. In this experiment, the desired confining pressure was 1, 2, 3, 4, and 5 MPa, respectively. The detailed contents of this experiment are shown in Table 3.

| Soil type | K0 coefficient | Axial loading rate (MPa/s) | Radial loading rate (MPa/s) |

| Sands | 0.32 | 10×10-5 | 3.2×10-5 |

| Loess | 0.34 | 10×10-5 | 3.4×10-5 |

| Soil type | Loess | Sands |

| Frozen soil temperature (℃) | -2, -5, -7, -10 | -7, -10 |

| The applied pressure (MPa) | 1, 2, 3, 4, 5 | 1, 2, 3, 4, 5 |

2) Freezing stage. The axial pressure and confining pressure were removed gradually, and then the K0-consolidated sample was taken out of the pressure cell and encased with a supporting copper jacket to prevent radial deformation during freezing. The K0 consolidated sample was returned to the pressure cell and load the axial stress to the value the K0 consolidation stage reached. Thus, we could assume that the sample had already been restored to the statue at the end of K0 consolidation stage. The minus temperature that the sample was expected to achieve was set, and then the cold bath started to work. When the pressure cell temperature went below 0 ℃, the sample volume began to change as the sample temperature decreased. Limited by the copper jacket, the radial deformation was observed as zero, and the variation of axial deformation was recorded to indicate the volume variation of the tested sample.

3) Thawing stage. The pressure cell's temperature was reset to 1 ℃ and maintained for the whole thawing stage. The soil sample's temperature began to increase by degrees as soon as the pressure cell's temperature increased. Because the highest temperature of the pressure cell was set to 1 ℃, the highest temperature of the tested samples could not exceed 1 ℃. In this way, the influence of the boundary temperature variation could be avoided.

3 Results and discussion 3.1 The characteristic of the freezing-thawing deformationSoil's freezing-thawing process is essentially a freezing-thawing process of the soil's pore-water. According to the research results at low pressures, when the soil temperature is lowered below freezing, the water contained in the soil void freezes into ice, accompanied by the ice's volume expansion of about 9%. This expansion brings about an increase in the intervals between soil particles and leads to an increase in soil volume. Conversely, when the temperature begins to rise, the pore-ice turns into pore-water, and the soil volume begins to reduce (Song et al., 2007). The change in soil volume causes some changes in the soil's physical properties, involving specific surface area, the soil-solution osmotic pressure, the pores' size distribution, particle-packing geometry, porosity, and particle size. All of these changes further govern the frozen soil's phase composition (Chamberlain and Gow, 1979; Graham and Au, 1985; Eigenbrod, 1996; Perkins and Sjuren, 2009). But for soil buried in deep alluvium, high pressure affects the phase-change temperature of the pore-water, which impacts the volume variation in freezing soil (Chamberlain, 1981). So the changes in physical properties have potential impacts on the mechanical properties of a frozen wall and the stability of surrounding buildings. Therefore, it is necessary to determine the freezing-thawing deformation for a soil subjected to high pressure for further interpreting its mechanical behavior.

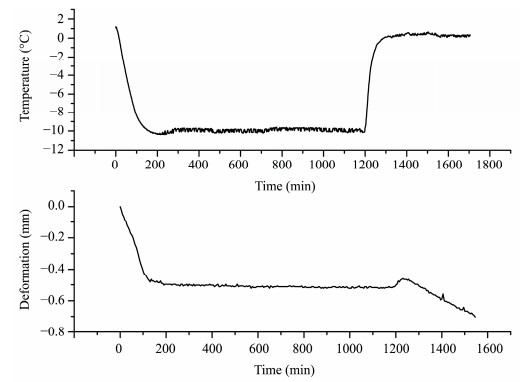

Figure 1 shows the results of a selection of freezing-thawing deformation (which is defined as the variation of sample height, namely the height obtained in the process of freezing-thawing minus the height after the sample consolidation was finished) plotted against time. As for the other samples tested, the freezing-thawing deformation had a trend similar to that shown in Figure 1. From Figure 1, we find that, for all the samples with various desired temperatures (from 0 ℃ to -10 ℃), their height decreased abruptly when the environmental temperature dropped to the desired temperature over a short time. After the environmental temperature reached the desired level and was kept constant, the height of the sample arrived at a stable state and would keep constant indefinitely. However, when the environmental temperature rose to 1 ℃ and remained relatively constant, the height of the sample had a tiny increment and then began to decrease. Limited by the capacity of the data-collection system, the thawing process of the tested samples lasted for only about 5~6 hours. Figure 1 shows that the sample height reduces during its thawing period. This finding differs from previous results, which were obtained from soils under low pressure or without added pressure, where the sample volume expanded in its freezing process and contracted in its thawing process.

|

| Figure 1 The freezing-thawing deformation process of a consolidated soil sample |

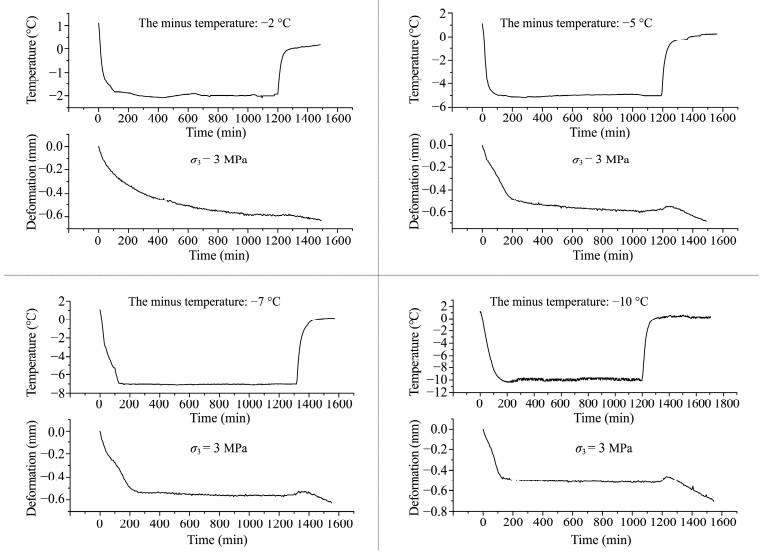

The environmental temperature versus time curves and the longitudinal deformation of the tested sample versus time curves are given in Figure 2. In this study, all of the samples tested are subjected to a pressure of 3 MPa when they are frozen or thawed to a desired temperature. Here, the desired negative temperature was that of the sample frozen (in this test, -2, -5, -7 and -10 et al, respectively), and the desired positive temperature was 1 ℃ for all the samples tested. To ensure the sample tested was frozen completely and its desired temperature attained, the sample was kept over 17 hours at its desired negative temperature status before the environmental temperature was adjusted to another status. Figure 2 indicates that the amount of the freezing-thawing deformation for a sample under high pressure depended on the temperature to which the sample was frozen. When the frozen soil's temperature was lowered below -5 ℃, the freezing deformation developing during the temperature-dropping process kept pace with the environmental temperature variation. That is to say, the height of the samples tested reduced abruptly with the dropping environment temperature, and reached its stable status when the environment temperature was lowed to its desired temperature. For the samples consolidated under the pressure of 3 MPa, the maximum freezing deformation of the tested sample was between 0.5 and 0.6 mm, as shown in Table 4. The maximum freezing deformation is independent of the temperature the sample arrived finally in frozen state. When the environmental temperature was gradually increased to 1 ℃ and the frozen soil began to thaw, the sample height had a slight increment of 0.04~0.05 mm before it began to reduce again. From Figure 2, it is observed that this slight increment would be independent of the frozen soil's temperature and the other conditions. But for the frozen soil with a temperature near -2 ℃, the height of the sample usually continued a reducing trend throughout the test period, even if the environmental temperature rose to 1 ℃. Figure 2 also indicates that the reducing trend of the sample height would not be changed in a short period.

|

| Figure 2 The environmental temperature versus time curves and the longitudinal deformation versus time curves for samples under the pressure of 3 MPa |

| Frozen soil temperature (℃) | -2 | -5 | -7 | -10 |

| Maximum freezing deformation (mm) | -- | 0.5930 | 0.5633 | 0.5180 |

For soils under the same pressure, apart from changing in temperature, the other external factors affecting volume changes in samples tested were invariable throughout the freezing-thawing process. For instance, the stress was kept constant and equal to that at the end of consolidation, the drainage valve was closed to stop the outside water inflow or the soil moisture outflow, and the copper jacket covered the sides of the tested sample to prevent radial deformation during the freezing-thawing process. So the deformation during the freezing-thawing process could only have been caused by the temperature changes. With the sample's temperature increasing and decreasing, a series of changes take place in the interior of the sample, such as the change in soil particles size, a realignment of the soil particles, a phase transfer, and a redistribution of the pore moisture. All of these changes cause a macro change in the tested sample, shown in this study by a reduction in sample height. As for the pore-moisture, when the soil temperature drops below the frozen temperature, some pore-moisture converts into ice and some moves about. As for the soil particles, according to the thermal expansion and contraction effects of some solid materials, the soil particle expands in size when heated and contracts when cooled. Given the thermal dilatation equal to the thermal contraction, the amount of thermal contraction of all the soil particles could be obtained by estimating the amount of thermal expansion during the thawing process.

Figure 2 shows the temperature and the deformation versus time curves for the soils subjected to 3 MPa pressure. From Figure 2, we find that for all the samples tested, when the desired temperature is lower than -5 ℃, the height of the soil sample has a slight increment, up to around 0.05 mm, at the beginning of the thawing stage. This increment is independent from the effects of the pressure applied and nearly equal for samples with different temperatures. So we can consider the contraction in the period of decreasing soil temperature is 0.04~0.05 mm, accounting for only 7%~9% of the total deformation. The rest of the deformation, accounting for more than 90% of all deformation, might be caused by the soil particles' realignment, the soil-water-ice transformation, and the pore-moisture redistribution.

The results obtained from the creep behavior of the fine-grained frozen soils indicated that when a sustained load was applied on a frozen soil, the creep deformation developed with time as a result of the contributions from the viscous flow of existing unfrozen water in the soil and a phase change in the ice matrix due to the pressure-melting of ice (Wijeweera and Joshi, 1991). That means the unfrozen water flowing and the ice-water phase transformation in frozen soils are the primary influential factors in producing creep deformation. For soils under higher pressure, their deformations occurring in the freezing-thawing process are closely identical with the creep deformation. So it is appropriate to considering the sample-height variation in the freezing-thawing process as a creep deformation led by temperature disturbance. As shown in Figure 2, for the soils under applied higher pressure, the creep developing with time during the freezing-thawing process depends on the temperature of the frozen soil. Based on the characteristics of different creep curves (Andersland and Ladanyi, 2003), it is observed from Figure 2 that when the frozen soil temperature is below -5 ℃, the soil deformation exhibits attenuation creep behaviors, whereas it presents a non-attenuation creep behavior when the frozen soil's temperature is between -2 and -5 ℃.

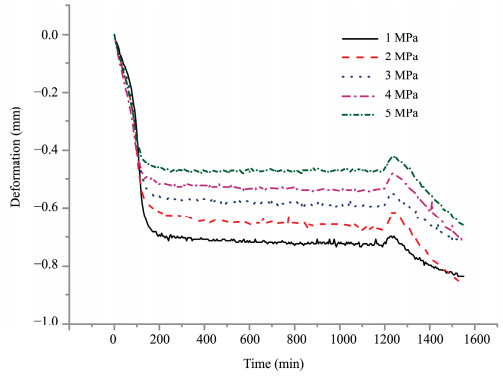

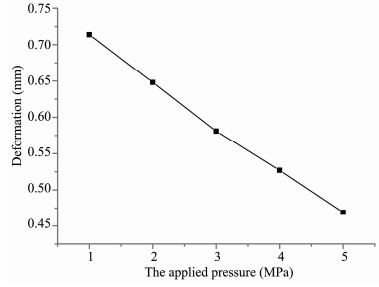

3.3 The effects of the applied pressureWhen considering the effect of the pressure on freezing-thawing deformation, a series of freezing-thawing tests has been conducted for loess samples under different applied pressures of 1, 2, 3, 4, and 5 MPa, respectively. The temperature of these tested sample was dropped to -10 ℃ when their deformations no longer increases under given constant pressure. The results for deformation versus time are shown in Figure 3. From Figure 3, it can be observed that the deformation for all the tested samples in their freezing stage has a similar trend. In other words, the heights of all the samples tested decreased abruptly with the decreasing sample temperature and became stable after the desired temperature for the sample was obtained and kept constant. As for the amount of the deformation, it strongly depended on the applied pressure. The amount of deformation decreased linearly with the increasing applied pressure, as shown in Figure 4. In the case of thawing deformation, considering the working time of the test machine, the experiment only lasted for a short time after the sample reached 1 ℃. So we can analyze the deformation that happened in the limited time span. As shown in Figure 3, each curve shows a slight increment of 0.04~0.05 mm after the thawing process has just began. This increment is independent of the applied pressure effects and nearly equal in all samples with a desired temperature of -10 ℃. Similar increments are also observed for the other experiments with different applied-pressure conditions. The average expansion for every test is given in Table 5.

|

| Figure 3 The effects of the applied pressure |

|

| Figure 4 The effects of the applied pressure on the maximum freezing deformation |

| Confining pressure (MPa) | 1 | 2 | 3 | 4 | 5 |

| Height increment (mm) | 0.04 | 0.05 | 0.04 | 0.05 | 0.05 |

It is widely accepted that soil type is one of the main factors governing the mechanical characteristics of frozen soils. As for the frozen sand and frozen loess experiencing K0 consolidation before the freezing stage began, Ma et al. (2002) conducted many experiments to study their respective strength and developed empirical constitutive models to predict the strength of different soil types as a function of temperature and confining pressure. Wang et al. (2007) investigated the influence of soil type on soil stiffness and concluded that even for the samples consolidated to the same confining pressure and frozen at the same negative temperature by the same method, soil type would not influence the value of yield strain; but it would have a significant effect on the magnitude of stiffness and the rate of stiffness degradation during shearing, thus changing a frozen soil's ability to resist deformation. Based on the above research, the authors infer that for the soils with high applied pressure, the soil type must have a significant influence on freezing-thawing deformation.

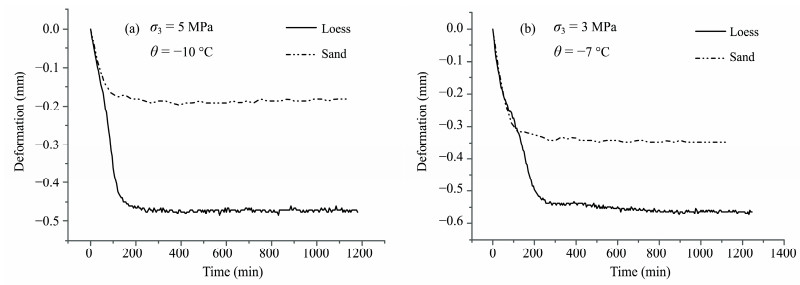

For sand and loess with a confining pressure of 5 MPa and a temperature of -10 ℃, the freezing deformation developments are shown in Figure 5a, along with the results of the same type of soils under 3 MPa pressure and -7 ℃ temperature (Figure 5b). From Figure 5, we find that, under the same pressure and the same environmental temperature, both sand and loess present an attenuation creep deformation in the freezing stage. But compared with the sand deformation in the freezing stage, the loess deformation is greater. The other test results for samples under various pressures are summarized in Table 6. The data for every experiment indicate that the difference among the freezing deformations are scattered within a narrow region, with a mean value around 0.35 mm.

|

| Figure 5 The effects of soil type on the freezing deformation |

| Pressure (MPa) | 1 | 2 | 3 | 4 | 5 | |||||||

| Deformation (mm) | Loess | 0.7214 | 0.5858 | 0.5364 | 0.6541 | 0.471 | ||||||

| Sand | 0.3209 | 0.2715 | 0.2445 | 0.2012 | 0.183 | |||||||

| Difference | 0.4005 | 0.3143 | 0.2919 | 0.4529 | 0.288 | |||||||

A series of freezing-thawing tests was performed on consolidated samples under high pressure to study the influence of the stratum depth, frozen soil temperature, and soil type on the freezing-thawing deformation when the artificial freezing method is applied to excavating deep alluvium. Here, the pressure from the stratum depth was represented by a pressure after consolidation. The main conclusions derived from this experimental study are as follows:

1) For the K0-consolidated soils under high pressure, when the environmental temperature is lower than 0 ℃ and the soils begin to be frozen, the soil sample height shows a decrease as temperature decreases; when the environmental temperature increases and the soil begins to thaw, the soil sample height shows a slight increase at the beginning of thawing and then starts to decrease for the rest of the test period.

2) The total deformation in soil particles caused by the freezing-thawing action is about 0.04~0.05 mm for the loess tested, accounting for only about 7%~9% of the total deformation. More than 90% of the deformation was caused by soil particles' realignment, water-ice phase transformation, and pore-moisture redistribution.

3) Based on the creep definition for frozen soils and its causes, we consider the freezing-thawing deformation under higher pressure to be creep deformation produced by temperature disturbance. Different temperatures have different forms of creep. For soils with a desired temperature between -2 ℃ and -5 ℃, a non-attenuation creep develops, while for soils with a desired temperature lower than -5 ℃, a full attenuation creep develops.

4) When the freezing deformation becomes stable, its maximum value depends on the applied pressure and the soil type. As the applied pressure increases, the maximum deformation decreases gradually. Under the same temperature and the same applied pressure, loess deformation is generally greater than that of sand.

Acknowledgments:This research was supported by a grant from the National Natural Science Foundation of China (No. 41671069, No. 41630636) and Foundation of the State Key Laboratory of Frozen Soil Engineering (SKLFSE-ZT-31).

| Alkire BD, Andersland OB, 1973. The effect of confining pressure on the mechanical properties of sand-ice materials. Journal of Glaciology, 12(66): 469–481. |

| Andersland OB, Ladanyi B, 2003. Frozen Ground Engineering. 2nd edition. John Wiley and Sons, Inc., New York. |

| Chamberlain EJ, 1981. Overconsolidation effects of ground freezing. Engineering Geology, 18(4): 97–110. |

| Chamberlain E, Groves C, Perham R, 1972. The mechanical be-havior of frozen earth materials under high pressure triaxial test conditions. Geotechnique, 22(3): 469–483. DOI: 10.1680/geot.1972.22.3.469 |

| Chamberlain EJ, Gow AJ, 1979. Effect of freezing and thawing on the permeability and structure of soils. Engineering Geology, 13: 73–92. DOI: 10.1016/0013-7952(79)90022-X |

| Cui G, 1998. Mechanics of frozen soil for deep alluviuma new field of frozen soil mechanics. Journal of Glaciology and Geocryology, 20(2): 97–100. |

| Eigenbrod KD, 1996. Effects of cyclic freezing and thawing on volume changes and permeabilities of soft fine-grained soils. Canadian Geotechnical Journal, 33: 529–537. DOI: 10.1139/t96-079-301 |

| Graham J, Au VCS, 1985. Effects of freeze-thaw and softening on a natural clay at low stresses. Canadian Geotechnical Journal, 22: 69–78. DOI: 10.1139/t85-007 |

| Harris JS, 1995. Ground Freezing in Practice. Published by Thomas Telford Service Ltd., Thomas Telford House, pp. 4-14. |

| Huang J, Yang W, Zhou G, 1997. Mechanism and prevention techniques of fracture shaft lining failure in the special stratum (Part three). Journal of China University of Mining and Tech-nology, 26(3): 10–13. |

| Jessberger HL, 1980. Theory and application of ground freezing in civil engineering. Cold Regions Science and Technology, 3(1): 3–27. DOI: 10.1016/0165-232X(80)90003-8 |

| Li K, Wang C, Chen X, 1993. Deep consolidation of frozen soils in triaxial tests. Journal of Glaciology and Geocryology, 15(2): 322–324. |

| Lu H, Yang W, Cheng X, 1997. Mechanism and prevention tech-niques of fracture shaft lining failure in the special stratum (Part two). Journal of China University of Mining and Technology, 26(2): 1–4. |

| Ma W, Chang X, 2002. Analyses of strength and deformation of an artificially frozen soil wall in underground engineering. Cold Regions Science and Technology, 34(1): 11–17. DOI: 10.1016/S0165-232X(01)00042-8 |

| Ma W, Wang D, 2012. Status quo and reflections of the deep frozen soil mechanics. Chinese Journal of Geotechnical Engineering, 34(6): 1123–1130. |

| Ma W, Wu Z, Chang X, 2000. Effects of consolidation process on stress-strain characters of frozen soils. Rock and Soil Me-chanics, 21(3): 198–200. |

| Ma W, Wu Z, Zhang L, et al, 1999. Analyses of process on the strength decrease in frozen soils under high confining pressure. Cold Regions Science and Technology, 29(1): 1–7. DOI: 10.1016/S0165-232X(98)00020-2 |

| Ma Y, 1979. Theory and practice of shaft subjected to ground pressure in deep alluvium. Journal of China University of Mining and Technology, 2: 45–69. |

| Perkins SW, Sjuren M, 2009. Effect of cold temperatures on properties of unfrozen Troll clay. Canadian Geotechnical Journal, 46: 1473–1481. DOI: 10.1139/T09-041 |

| Song W, 2007. Effective thermal expansion coefficient of frozen granite soil. Canadian Geotechnical Journal, 44(10): 1137–1147. DOI: 10.1139/T07-047 |

| Wang DY, Ma W, Wen Z, et al, 2007. Stiffness of frozen soils subjected to K0 consolidation before freezing. Soils and Foun-dations, 47(5): 991–997. DOI: 10.3208/sandf.47.991 |

| Wang D, Ma W, Chang X, 2004. Analyses of behavior of stress-strain of frozen Lanzhou loess subjected to K0 consolidation. Cold Regions Science and Technology, 40(1): 19–29. |

| Wang D, Ma W, Wen Z, et al, 2008. Study on strength of artificially frozen soils in deep alluvium. Tunnelling and Underground Space Technology, 23(4): 381–388. DOI: 10.1016/j.tust.2007.06.010 |

| Wijeweera H, Joshi RC, 1991. Creep behavior of fine-grained frozen soils. Canadian Geotechnical Journal, 28: 489–502. DOI: 10.1139/t91-066 |

| Yang W, Huang J, 1999. Theoretical analyses and experimental research on stress in freezing pipes. Journal of Glaciology and Geocryology, 24(1): 33–38. |

| Yang W, Lu H, 1996. Fracture mechanism and prevention of the shaft lining lying in thick overburden. Proceedings of the '96 International Symposium on Ming Science and Technology. Rotterdam, Netherlands:A.A. Balkema Publishers, pp. 345-348. |

2017, 9

2017, 9