Article Information

- HongYe Yan, GuoTang Zhao, DeGou Cai, QianLi Zhang, JianPing Yao, AiJun Cheng. 2015.

- Investigation of insulation layer dynamic characteristics for high-speed railway

- Sciences in Cold and Arid Regions, 7(4): 430-437

- http://dx.doi.org/10.3724/SP.J.1226.2015.00430

Article History

- Received: March 21, 2015

- Accepted: May 19, 2015

2. China Railway Corporation, Beijing 100844, China

1 Introduction

To tie in with national and international strategic planning, the construction of high-speed railways has been significantly extended in both the northeastern and northwestern areas of China. By the end of March 2015, a total length of 7, 000 km high-speed railway lines are in operation under construction. In addition, with the introduction of the "One Belt and One Road" plan, representing a total length of more than 7, 000 km of high-speed railway, lines called the "Eurasian high-speed transport corridor" will be constructed. These high-speed railway lines are located across frozen soil, so problems due to the seasonal frost soil or permafrost subgrade must be carefully considered.

A reasonable anti-frost structure is the key to prevent frost heave in the high-speed railway subgrade. At present, an anti-frost structure in the severe cold region of China is designed based on frost resistant filler combined with waterproof and drainage principles(Ye et al., 2007). The anti-frost filler will be used to fill the subgrade in the range of frost depth, and waterproof sealing measures will be used in the subgrade surface. Qi et al.(2013)verified the rationality of the anti-frost structure design. Zhao et al.(2011)explained the anti-frost treatment measures of the Passenger Dedicated Line subgrade in a seasonal frozen soil region. Wang et al.(2014)integrated and analyzed the monitoring results of high-speed railway subgrade frost heave; then summarized the reasons causing the frost heave. Yan et al.(2015)proposed the required thermal insulation material and its thickness to eliminate frost injury, and then formed the construction technology process of the thermal insulation board. From the current situation of frost heave research, some positive effects have been obtained. However, due to the unknown frost heave mechanism of weak frost heave filler and lack of construction quality control, the surface sealing measures became ineffective in some sections. Therefore, limited frost heave has occurred in these sections, which affects track irregularity.

Moreover, Sheng et al.(2003), Su and Gao(2003), Wen et al.(2005a, b; 2006), Lv et al.(2007), Su et al.(2007), Liu(2010), Xin(2012), Wang and Liu(2014)have also researched the insulation layer material, but tests have not been validated in field.

Installing insulation material under the high-speed railway subgrade to prevent frost heave is an effective and economic technical measure; this method has been successfully applied in some existing ballasted railways. The thermal insulation performance of this approach has been verified, but at present has not been introduced into the design of anti-frost structures for high-speed railway subgrades with ballast-less track. This paper systemically describes the elastic and accumulated deformation behavior of insulation material under different train loads by using indoor dynamic load testing and in-situ structure dynamic load testing. This information could provide a test reference for the design of anti-frost structure using insulation material for high-speed railway subgrades in severely cold regions.

2 Insulation material thermal performance testCommon XPS thermal insulation board was used as test material in the thermal performance test. Table 1 shows test results based on the "thermal insulation extruded polystyrene foam(XPS)" from the National construction material quality supervision and inspection center. As presented in Table 1, heat resistance was greater than 0.89(m2∙K)/W and thermal conductivity coefficient was less than 0.028 W/(m∙K)when the temperature was between 10 °C and 25 °C. This indicates that the XPS is an excellent heat insulating material; the compressive strength could achieve 150 kPa, satisfying the control requirements of high-speed railway subgrade.

| No. | Test item | St and ard requirement | Test result |

| 1 | Compressive strength | ≥150 kPa | 304 kPa |

| 2 | Moisture absorption, soak 96 hours(volume fraction) | ≤1.5% | 0.4% |

| 3 | Moisture permeability factor(23±1 °C, RH 50%±5%) | ≤3.5 ng/(m∙s∙Pa) | 1.9 ng/(m∙s∙Pa) |

| 4 | Thermal resistance(thickness 25 mm, average temperature 10 °C) | ≥0.89(m²∙K)/W | 0.896(m2∙K)/W |

| Thermal resistance(thickness 25 mm, average temperature 25 °C) | ≥0.83(m2∙K)/W | 0.890(m2∙K)/W | |

| 5 | Thermal conductivity coefficient(average temperature 10 °C) | ≤0.028 W/(m∙K) | 0.0269 W/(m∙K) |

| Thermal conductivity coefficient(average temperature 25 °C) | ≤0.030 W/(m∙K) | 0.0290 W/(m∙K) | |

| 6 | Density | -- | 36.71 kg/m3 |

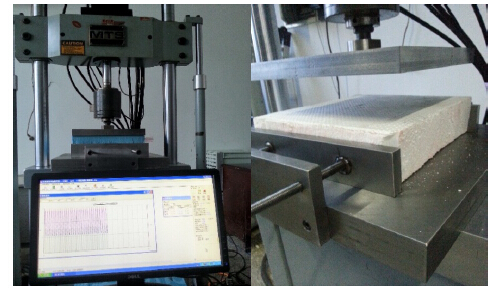

The loading equipment in this test is an American MTS universal material-testing machine with a rated load of 100 kN. This multi-channel fully digital-coordinated loading control system was used to control the load mode, with the load-control mode selection.

1)Test scheme

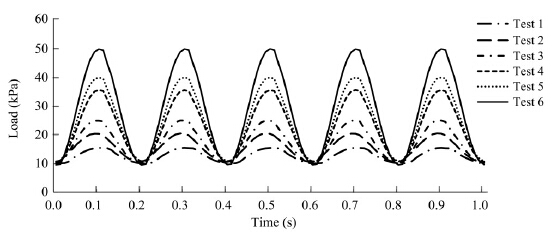

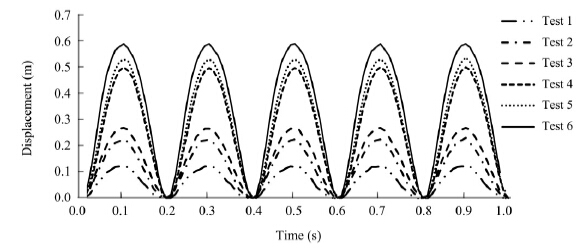

In conformance with the actual situation of high-speed railway train loads, six different dynamic loads was set as the basis of 10 kPa vertical static load; the applied frequency is 5 Hz, with 800, 000 applications. Table 2 shows the specific design scheme, and the experimental results are presented in Figures 1, 2 and 3.

| Scheme | Basic load(kPa) | Dynamic load(kPa) | Applied times(ten thous and s) | Frequency(Hz) |

| 1 | 10 | 5 | 80 | 5 |

| 2 | 10 | 10 | 80 | 5 |

| 3 | 10 | 15 | 80 | 5 |

| 4 | 10 | 25 | 80 | 5 |

| 5 | 10 | 30 | 80 | 5 |

| 6 | 10 | 40 | 80 | 5 |

|

| Figure 1 MTS testing equipment |

|

| Figure 2 Load applied |

|

| Figure 3 Test waveform |

2)Test results analysis

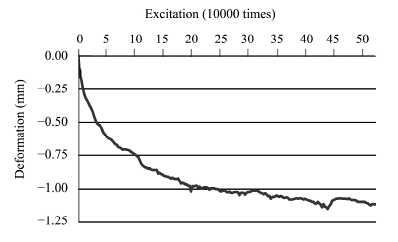

During the testing process, the downward fluctu-ating equilibrium position was used as the datum for measuring plastic deformation as presented in Figure 4.

|

| Figure 4 Plastic deformation(scheme 6) |

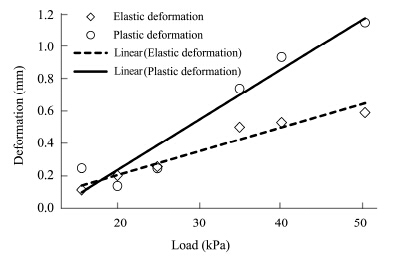

Table 3 and Figure 5 show that elastic deformation increases with increasing load; under the 6th test condition, the dynamic elastic deformation reached 0.591 mm, and the plastic deformation was 1.148 mm. This was an increase of approximately 5 times over the 1st test condition. Table 3 shows that the dynamic elastic modulus of the insulation board was in the range of 4.7-6.8 MPa.

| No. | Recommended load(kPa) | Actual load(kPa) | Dynamic elastic modulus(MPa) | Dynamic elastic deformation(mm) | Plastic deformation(mm) |

| 1 | 15 | 15.49 | 4.7 | 0.117 | 0.249 |

| 2 | 20 | 19.89 | 4.8 | 0.204 | 0.141 |

| 3 | 25 | 24.79 | 5.7 | 0.258 | 0.248 |

| 4 | 35 | 34.91 | 5.0 | 0.500 | 0.739 |

| 5 | 40 | 40.09 | 5.7 | 0.530 | 0.933 |

| 6 | 50 | 50.37 | 6.8 | 0.591 | 1.148 |

|

| Figure 5 Tendency of elastic deformation |

Figure 5 illustrates that both elastic deformation and plastic deformation of XPS thermal insulation material increase almost linearly with an increase of applied load, However, the magnitude of plastic deformation increases more than that of elastic deformation. This is due to internal breakage of the thermal insulation material during the loading process. A greater load will cause greater damage, resulting in large plastic deformation.

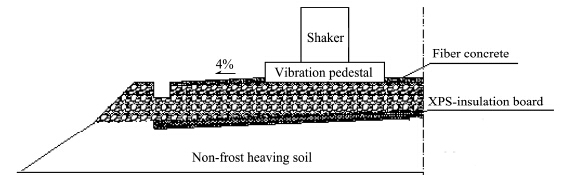

4 The in-situ dynamic test of insulation structure1)Test scheme

The test site was located in the DK140 subgrade test section of the Harbin-Dalian high-speed railway, and was filled in accordance with the requirements of high-speed railway subgrade. The thickness of the subgrade surface layer was 0.7 m and it was mixed with 5% cement graded crushed stone. The bottom layer of the subgrade was filled with anit-frost-resistant filler 2.3 m in thickness. 0.1-m-thick XPS insulation board was used between the subgrade surface layer and the bottom layer. The earth pressure boxes, accelerometer, and settlement plate were pre-buried to test for stress, deformation, and other parameters, as presented in Figure 6.

|

| Figure 6 Subgrade structure in the test section |

The SBZ30 dynamic-loading test machine simulated the dynamic load, as presented in Figure 7. The test machine was installed on the line through a vibration pedestal and by adjusting the frequency and vibration phase of the eccentric block. A variety of excitation forces could be produced which simulates the dynamic load caused by a high-speed train. The vibration pedestal was formed with cast-in-place reinforced concrete, as presented in Figure 8. The vibration pedestal can transmit the exciting force from the dynamic loading test machine to the subgrade of a high-speed railway. The size(length × width × height)of vibration pedestal in this test was 4.8m×3.0m×2.5m, and it was directly cast in place beyond the support layer.

|

| Figure 7 SBZ30 dynamic loading test machine |

|

| Figure 8 Vibration pedestal |

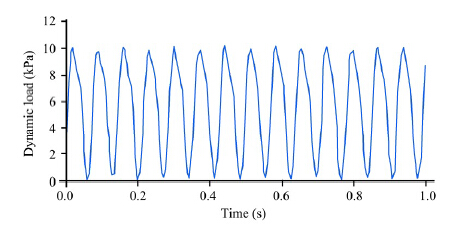

The dynamic stress follows the attenuation rule in the depth direction, and can be reduced more than 50% at the bottom layer of the subgrade. The typical measured dynamic stress values on the subgrade surface layer ranges from 11 to 16 kPa for the Wuhan-Guangzhou, Beijing-Tianjin, and Beijing-Shanghai high-speed railway lines. The insulation board was laid between the bottom layer and the subgrade surface layer; the applied dynamic load was controlled to 5-10 kPa. According to the in-situ response effect of dynamic loading, the applied frequency should be controlled at about 14 Hz, with ten million repetitions. The frequency of the data test was one data acquisition for every hundred thous and loading times; the static settlement test was performed simultaneously. A multi-channel 24-bit high-precision data-acquisition instrument with a sampling frequency of 1, 024 Hz was used. The time duration for each data acquisition was 5 s to ensure that the amount of data collected met the data analysis requirements.

2)Analysis of different levels of load test results

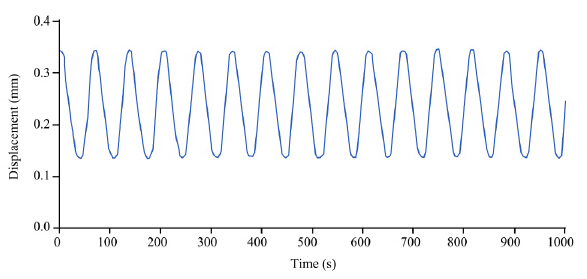

During the loading process, the dynamic stress can be monitored with an earth pressure box located beyond and underneath the insulation layer. A typical dynamic stress waveform is presented in Figure 9.

|

| Figure 9 Typical dynamic stress waveform |

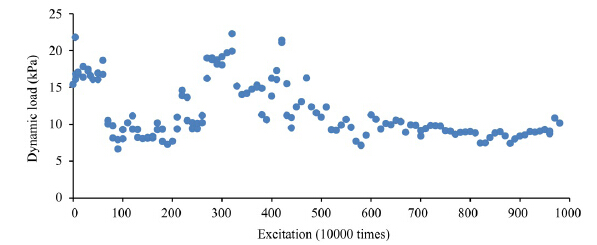

Dynamic load tests under different test stress levels should first be made to test the elastic deformation and cumulative deformation of the insulation material. After determining the general deformation behavior, the long-term dynamic vibration test with load level of 5-10 kPa should be performed to further study the durability and the power performance of the thermal insulation material. The dynamic stress levels used in the long-term dynamic load test are presented in Figure 10.

|

| Figure 10 Dynamic stress levels of long-term dynamic load test |

The elastic deformation of the insulation layer can be measured with an eddy-current displacement gauge installed on the attached rod of the settlement plate. The dynamic displacement beyond and underneath the insulation board relative to the settlement base rod should first be measured. Then, the elastic deformation of the insulation board can be calculated from the former dynamic displacement values. A typical dynamic displacement waveform is presented in Figure 11.

|

| Figure 11 Typical dynamic displacement waveform |

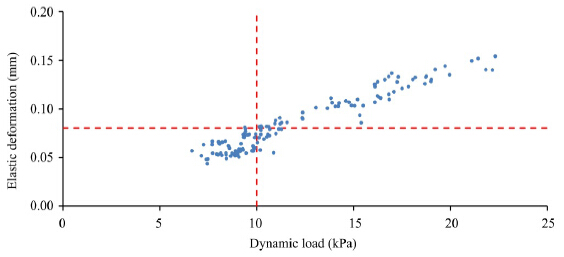

The elastic deformation of the insulation board is related to the applied dynamic stress level. From the test results of elastic deformation under different dynamic stress levels, a correlation curve could be developed as presented in Figure 12.

|

| Figure 12 Range of insulation board elastic deformation of high-speed railway train |

The maximum applied dynamic stress level during testing is about 2.5 times greater than that produced by a high-speed railway train. The test curve shows that there is a linear relationship between elastic deformation and the dynamic stress level of an insulation layer, indicating that the insulation layer is still within the range of elastic deformation. Considering the in-situ sensor burial condition, the elastic modulus of insulation layer can be approximately estimated as 7 MPa according to the correlation curve of elastic deformation and dynamic stress level, and this is consistent with indoor testing results. It can be seen from the Figure 12 that the dynamic deformation of the insulation layer was within 0.08 mm, within the range of dynamic stress level of high-speed railway train and therefore of little influence with respect to track irregularity.

3)Analysis of long-term dynamic load test results

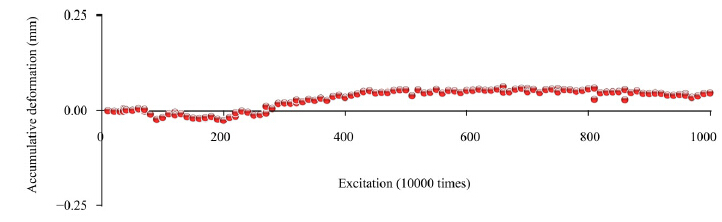

The same sensor was used in both accumulative deformation and elastic deformation measurements of the insulation layer. After the dynamic data acquisition of every 100, 000 occurrences of load applied, the static measurement of settlement plates should be made rapidly after stopping the vibration, then restorating the excitation. From the initial value of static measurement and the observed values of each static measurement, the settlement beyond and underneath the insulation board relative to the settlement base rod can be calculated. Then, the accumulative deformation of insulation board can be developed from the former relatively settled values. The dynamic accumulative deformation of the insulation layer under dynamic load is an index that can be adapted to the high-speed railway environment. This small value was conducive to maintaining the elevation and regularity of a high-speed railway line.

Figure 13 shows the cumulative deformation test curve after applying ten million occurrences of dynamic load. It can be seen from Figure 13 that in the loading process with a variety of dynamic stress level, there is a developing trend of accumulative deformation with relatively slow rate of development, at which point the dynamic stress reaches a higher level. Under the dynamic loading of a high-speed railway, the accumulative deformation of the insulation layer tends to be stable. The accumulated deformation of the insulation layer was 0.06 mm after applying ten million occurrences of dynamic load(equivalent to an actual dynamic load interval of 15 years), in agreement with the results of the elastic deformation test. The accumulated deformation value was within the range of elastic deformation, which had only a small influence on the irregularity of a high-speed railway line.

|

| Figure 13 Accumulative deformation of insulation layer under long-term dynamic load |

After performing a thermal insulation performance test, a dynamic load test, and an in-situ dynamic load test on XPS thermal insulation material, the following conclusions can be drawn:

1)The heat resistance of XPS thermal insulation material was greater than 0.89(m2∙K)/W, and the thermal conductivity coefficient was less than 0.028 W/(m∙K), indicating that the XPS is an excellent heat insulation material. Also, the compressive strength could achieve 150 kPa, satisfying the control requirements of a high-speed railway subgrade.

2)The results from the six different indoor dynamic-load tests show that the elastic deformation of XPS thermal insulation material increases with an increase of applied load. The dynamic elastic modulus of XPS was in the range of 4.7-6.8 MPa. Both elastic deformation and plastic deformation of XPS thermal insulation material increase linearly with an increase of applied load. However, the magnitude of plastic deformation increases more than that of elastic deformation.

3)The in-situ dynamic load test indicated that there was a linear relationship between elastic deformation and the dynamic stress level of the insulation layer. Under dynamic loading of a high-speed railway, the dynamic deformation of the insulation layer was within 0.08 mm. After applying ten million occurrences of dynamic load, the accumulated deformation of the insulation layer was less than 0.06 mm. Subgrade structures using XPS insulation board therefore do not influence the irregularity of high-speed railway lines.

Acknowledgments: This work is supported by the China Railways Corporation research project entitled "The technical tests for the high speed railway subgrade frost heave prevention in the alpine"(Project No. Z2013-038), "The long term observation of frost-heave technology for Ha-Da high-speed railway during the operation”(Project No. Z2012-062) and "Optimal design for high-speed railway subgrade structure under different grade and environment"(Project No. 2014G003-A), and from the railway scientific and technological research and development center called "The mechanism and evolution rule of the graded gravel under freeze and thawing cycles for the high speed railway"(Project No. J2014G003) and "The disease control technology and equipment of gradating gravel in surface layer of subgrade bed"(Project No. 2013YJ032).| Liu D, 2010.The development of new-style composite structural insulation board.Thesis of Dalian University of Technology. |

| Lv GF, Yang YP, Wei QC,et al., 2007.Study of using thermo syphon-insulated board to enhance the stability of permafrost embankment. Journal of the China Railway Society, 6: 118-122. |

| Qi H, Hu XY, Li TG, et al.,2013.The study of high-speed railway subgrade anti-frost structure design method. Railway Construction, (04): 98-100. DOI: 10.3969 /j.issn.1003-1995.2013.04.30. |

| Sheng Y, Wen Z, Ma W, 2003. Preliminary analysis on insulation treatment of embankment at Beiluhe test section of Qinghai-Tibet Railway. Chinese Journal of Rock Mechanics and Engineering, (S2): 2659-2663. DOI:10.3321/j.issn:1000-6915.2003.z2.025. |

| Su GQ, Cao WH, 2003.Construction technology of heat-insulated slab subgrade at permafrost zone. Railway Construction Technology, (z1): 6-9. |

| Su Q, Wang X, Liu S, 2007. In-situ test on engineering application of new thermal-insulation materials in Qinghai-Tibet Railway subgrade. Journal of Southwest Jiaotong University, 4: 395-399. DOI: 10.3969/j.issn.0258-2724.2007.04.002. |

| Wang CL, Zhang RK, Zhao XM, et al., 2014. Frost heaving monitoring system and frost heaving rules for the high-speed railway embankment in the seasonally frozen soil regions.Journal of Glaciology and Geocryology, 36(4): 962-968. DOI:10.7522 /j.issn.1000-0240.2014.0116. |

| Wang M, Liu JJ, 2014. Study on anti-frost thickness of insulation in road engineering. Journal of Shihezi University (Natural Science), 1: 123-127. DOI: 10.3969/j.issn.1007-7383.2014.01.025. |

| Wen Z, Sheng Y, Ma W,et al., 2005a.Evaluation of application of the insulation to embankment in Qinghai-Tibetan Railway.Journal of Glaciology and Geocryology, 5: 694-700. |

| Wen Z, Sheng Y, Ma W,et al., 2005b.Numerical simulation on application of EPS in embankment engineering of Qinghai-Tibet Railway. Journal of the China Railway Society, 3: 91-96. DOI: 10.3969/j.issn.1000-0240.2004.z1.015. |

| Wen Z, Sheng Y, Ma W,et al., 2006.Analysis on the effect of permafrost protection by two-phase closed joint thermosyphon and insulation in permafrost regions.Journal of Lanzhou University (Natural Sciences), 3: 14-19. DOI: 10.3321/j.issn:0455-2059.2006.03.003. |

| Xin Q, 2012. Research on XPS Insulation Board Treatment Technology in Insular Permafrost Subgrade.Thesis of Chang'an University, Shaanxi, China. |

| Yan HY, Cai DG, Zhang L, et al., 2015. Study on railway subgrade's prevention of frost damage and warm-keeping technology. Railway Construction, (1): 51-55. DOI: 10.3969 /j.issn.1003-1995.2015.01.12. |

| Ye YS, Wang ZJ, Cheng AJ, et al., 2007.Frost heave classification of railway subgrade filling material and the design of anti-freezing layer. Chinese Railway Science, 28(1): 1-7.DOI: 10.3321/j.issn:1001-4632.2007.01.001. |

| Zhao RT, Li JH, Li SG, 2011. Anti-frost heave measures of subgrades for passenger-dedicated railways. Railway Investigation and Surveying, (04): 70-71.DOI: 10.3969/j.issn.1672-7479.2011.04.023. |

2015, 7

2015, 7