Article Information

- TianLiang Wang, ZuRun Yue, TieCheng Sun, JinChuang Hua. 2015.

- Influence of fines content on the anti-frost properties of coarse-grained soil

- Sciences in Cold and Arid Regions, 7(4): 407-413

- http://dx.doi.org/10.3724/SP.J.1226.2015.00407

Article History

- Received: February 8, 2015

- Accepted: April 26, 2015

2. Key Laboratory of Roads and Railway Engineering Safety Control of Ministryof Education, Shijiazhuang Tiedao University, Shijiazhuang, Hebei 050043, China;

3. Graduate School, Shijiazhuang Tiedao University, Shijiazhuang, Hebei 050043, China

1 Introduction

Coarse-grained soil(CGS), a type of cohesionless mixed soil made up of round gravel soil, breccias soil, gravel, coarse s and , and others, is widely used in engineering constructions such as earth-rock dams(Wang et al.,2009; Xu and Song, 2010; Zhu et al.,2011; Chu et al.,2012; Zhu et al.,2013; Jiang et al.,2014), highway subgrades(Zhang and Yang, 2012), and building foundations(Wang et al.,2011)because of its engineering characteristics such as poor water absorption, high water permeability, great filling density, less settlement and deformation, weak frost heave, and high bearing capacity. In particular, its application in subgrades of high-speed railways in frozen regions has been gradually met with engineering approval(Chen et al.,2011). In order to meet the deformation controlling st and ards for high speed railway(HSR)lines, the construction code for HSR subgrades(Code for Design of High Speed Railway HSR subgrades, 2009)currently specifies that the fines content of the coarse-grained soil(CGS)should be strictly controlled. Tests have indicated that the frost susceptibility of CGS decreases with the reduction in fines content; however, lower fines content could result in less compaction and therefore greater instability of the subgrade(Konrad and Lemieux, 2005; Zhang et al.,2007). The fines content will also have a direct influence on the strength properties of CGS due to the effects of repeated freezing and thawing. Therefore, for the proper use of CGS in HSR subgrades in frozen regions, it is of great practical engineering significance to study the influence rules of fines content on frost heave, compaction, and strength properties so as to determine the optimal fines content.

Previous relevant studies on the application of CGS as filling materials in earth-rock dams mainly focused on the strength properties and deformation behavior(Chu et al.,2012; Zhu et al.,2013), resilient characteristics(Zhu et al.,2011), particle breakage property(Wang et al.,2009), permeability(Jiang et al.,2014) and constitutive equation(Xu and Song, 2010). As a result, a large number of research results and engineering experiences have been accumulated, forming good references in the application of CGS in railway subgrades. However, past applications and research of CGS on railways and highways mainly focused on the construction technology and quality control techniques(Chai et al.,2004), and there has been relatively little research on the frost heave and strength properties of CGS.

Regarding the frost heave properties, Arenson and Sego(2006)used a fluorescent tracer to study the location of unfrozen water within CGS during the freezing process, while Lai et al.(2012)proposed a new structural embankment that had significantly less frost penetration and thaw depth than those of a CGS embankment. In terms of the effects of fines content on the frost heave susceptibility of CGS, Konrad and Lemieux(2005) and Konrad(2008)found that when the fines content of CGS is less than 7%, the frost heave deformation is relatively small. Moreover, frost susceptibility of well-graded crushed aggregates was found to increase with an incremental increase in fines content and kaolinite fraction(Konrad and Lemieux, 2005). The conclusions of Konrad and Lemieux(2005) and Konrad(2008)were supported by the results of other studies conducted under similar conditions(e.g., Vinson et al.,1986; Chen and Wang, 1989; Ye et al.,2007; Xu et al.,2011). According to further research conducted by Vinson et al.(1986), the particle size of fine-grained soil is also an important influencing factor on the frost heave susceptibility of CGS, while Zhang et al.(2007)found that the silt content was the most prominent factor causing frost heave susceptibility.

The aforementioned studies showed that fines content is an important factor influencing the frost heave susceptibility of CGS. However, there is no uniform st and ard to determine the optimal fines content of a given soil, and the differences among the prior results are notable. As for the strength properties, Jiang et al.(2010)analyzed the influence rules of geotextile layers, water content, and degree of compaction on the stress-strain relationship, the strength, and the deformation behavior of CGS. Using a homemade uniaxial rheometer, Chen et al.(2007)analyzed the rheological properties of CGS. However, there have been relatively few studies on the strength properties of CGS under repeated freezing-thawing, and the influence of fines content has not yet been considered.

Therefore, obtaining the influence rules of temperature and fines content on the frost heave and strength properties of CGS has become a serious engineering problem for HSR construction in deep seasonal frost areas. Accordingly, we studied the frost heave and strength properties of CGS influenced by freeze-thaw cycles and fines content, using a frost heave and thaw settlement system and a triaxial test apparatus.

2 Testing program 2.1 MaterialsPhysical properties of CGS. The studied CGS was a natural sedimentary fine round gravel soil, which was the subgrade material for the Harbin-Qiqihar Passenger Special Railway Line. The specific gravity was 2.69 g/cm3 for particle sizes larger than 5 mm, and was 2.60 g/cm3 for particle sizes smaller than 5 mm. The permeability coefficient was 6.22×10−4 cm/s. The size of the largest particles was 40 mm; those with particle sizes larger than 2 mm accounted for 72.61% of the total mass, and less than 0.075 mm made up 6.65% of the total mass. The coarse-grained soils' freezing point temperatures are shown in Table 1.

| FC(%) | 0 | 1 | 3 | 5 | 7 | 9 | 11 |

| Tf(°C) | −0.02 | −0.02 | −0.04 | −0.05 | −0.06 | −0.08 | −0.15 |

| Note: FC indicates fines content; Tf indicates the sample freezing temperature. | |||||||

Physical properties of fine-grained soil. The fine-grained soil mixed in the CGS was a type of silty soil with strong frost heave properties and susceptibility; its liquid limit was 29.1%, the plastic limit was 21.0%, and the plasticity index was 8.1.

2.2 Compaction testing programSt and ard compaction tests were conducted on CGS samples with fines contents of 0%, 1%, 3%, 5%, 7%, 9%, 11%, and 15%. The maximum dry density and optimal water content of CGS with different fines contents were obtained.

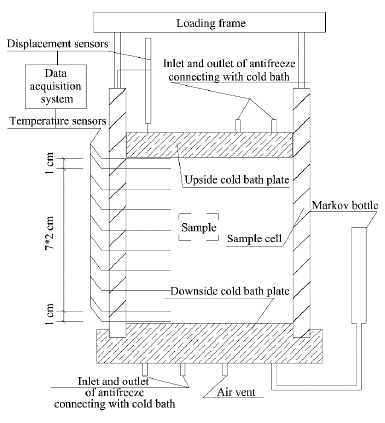

2.3 Frost heave testing programTo study the frost heave property of the CGS, we set up a frost heaving test system comprised of a sample tube, upside and downside cold bath plates, constant temperature cold baths, cotton insulation, a Markov bottle, temperature and displacement sensors, and a data acquisition system. The upside and downside cold bath plates were used to simulate the unidirectional freezing mode, as shown in Figure 1.

|

| Figure 1 Schematic diagram of the frost heave test device |

To study the influencing rules of fines content on the frost heave property of the CGS, fines contents of 3%, 5%, 7%, 9%, 11%, and 15% were tested. Given the preliminary test results, all samples were then prepared with the optimal water content. The diameter and height of these samples were 200 mm and 160 mm, respectively, and the soil was compacted layer by layer. In the frost heaving process, the temperature at the top of the samples was set to −5 °C and the temperature at the bottom was set to 1 °C, and the freezing time lasted for 48 hours.

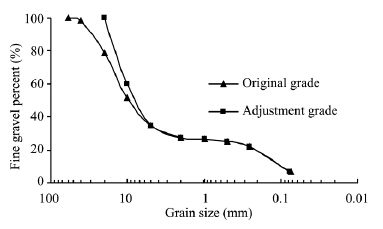

2.4 Strength testing programThe sample used in the triaxial test was 101 mm in diameter and 200 mm in height. In order to eliminate the size effect and ensure that the fines content of the CGS was unchanged, the equivalent substitution method was adopted. The original grade and adjustment grade curves of the CGS are shown in Figure 2.

|

| Figure 2 Grain size curve of fine round gravel soil |

In order to study the influencing rules of fines content on the strength property of the CGS, fines contents of 0%, 1%, 3%, 5%, and 7% were tested. Given the preliminary test results, all samples were then prepared with the optimal water content and a compaction degree of 95%. Then the samples were covered with a rubber membrane and cotton insulation, and were subjected to unidirectional freezing and thawing in the high-low temperature test apparatus. Based on soil temperatures measured in the field, the cooling temperature was set to −5 °C and lasted for 12 hours, and the thawing temperature was set to 5 °C and also lasted for 12 hours; the numbers of freezing and thawing cycles were set to 0, 1, 3, 6, 10, and 15.

In the triaxial shearing test process, the confining pressures were set to 50 kPa, 100 kPa, and 150 kPa, the loading rate was 0.4 mm/min, and the controlling strain was 5%. In the tests, parameters such as load and deformation were recorded.

3 Compaction test resultsByconducting the st and ard compaction test on the CGS, the maximum dry density and optimal water content with different fines contents were obtained and are listed in Table 2. The optimal water content of the CGS increased with the increasing increment of fines content, and then leveled off. However, the maximum dry density of the CGS first increased and then decreased with the increasing increment of fines content, which means that there was an optimal fines content in the range of 5% to 9%.

| Fines content(%) | ρdmax(g/cm3) | wopt(%) |

| 0 | 1.90 | 3.46 |

| 1 | 1.91 | 3.52 |

| 3 | 1.95 | 4.29 |

| 5 | 1.98 | 4.69 |

| 7 | 2.04 | 5.28 |

| 9 | 2.08 | 5.40 |

| 11 | 2.03 | 5.52 |

| 15 | 2.01 | 6.51 |

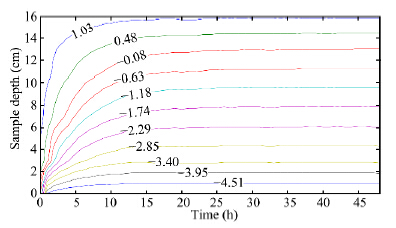

Figure 3 illustrates the isothermal diagram for the CGS sample with fines content of 9%. In the graph, the depth at 0 cm represents the cold side(−5 °C), and that at 16 cm represents the warm side(+1 °C). As listed in Table 1, the freezing temperature of CGS with fines content of 9% was −0.08 °C. Thus, the sample could be divided into frozen and unfrozen portions based on the freezing temperature of −0.08 °C, as shown in Figure 3. The depth at which the sample's internal temperature reached the freezing temperature(See Table 1)was considered as the frozen depth, and the frozen depths for all the samples are listed in Table 3.

|

| Figure 3 Temperature change curves of the CGS soil sample |

| Fines content(%) | Amount of frost heaving(mm) | Frozen depth(cm) | Frost heave ratio(%) |

| 3 | 0.82 | 13.89 | 0.59 |

| 5 | 0.97 | 13.63 | 0.71 |

| 7 | 0.98 | 12.06 | 0.81 |

| 9 | 1.22 | 13.18 | 0.93 |

| 11 | 1.35 | 12.45 | 1.08 |

| 15 | 1.54 | 13.47 | 1.14 |

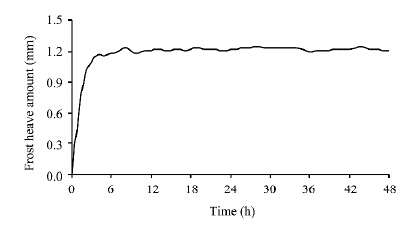

Figure 4 indicates the frost heaving process for the CGS sample with fines content of 9%. The frost heaving deformation first sharply increased and then leveled off after 6 h with no supply of water, and the amount of frost heaving was 1.22 mm.

|

| Figure 4 Changes in frost heave amount(9% fines content) |

To further investigate the frost heave susceptibility of the CGS, the frost heave ratio was considered. This ratio reflects the extent of frost heave susceptibility and is defined as the proportion of frost heave increment over frozen depth in a certain period(e.g., Ye et al.,2007; Xu et al.,2011).

| $\eta = \Delta h/{H_f}$ | (1) |

According to Equation (1), the frost heave ratios for the samples are listed in Table 3.

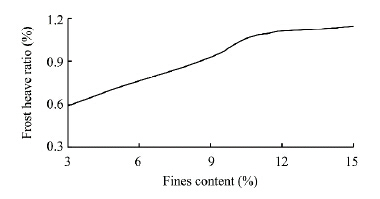

4.3 Effect of fines contentFigure 5 shows the relationship between fines content and the frost heave ratio of the CGS samples. The frost heave ratio increased with the increasing increment of fines content when the fines content was less than 10%; over 10%, the frost heave ratio leveled off. Considering the compaction results, we estimated the reasonable fines content to be 5%-7%, which could simultaneously achieve efficient compaction and weaker frost susceptibility.

|

| Figure 5 Curve of frost heave ratio vs. fines content |

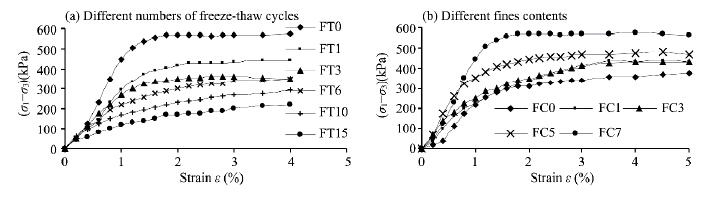

Figure 6 shows the stress-strain relationship of the CGS under different numbers of freeze-thaw cycles and fines contents. As shown in Figure 6a, the effect of freeze-thaw on the mechanical properties of the CGS samples is clear. At the same stress level, the strain increased with more freeze-thaw cycles. For the CGS samples with same number of freeze-thaw cycles, the effect of fines content on the mechanical properties is also clear, and the peak strength increased with the increasing increment of fines content, as shown in Figure 6b.

|

| Figure 6 Curves of stress-strain under different numbers of freeze-thaw cycles and fines content. FT1 means one freeze-thaw cycle, FC1 means a fines content of 1% in the CGS |

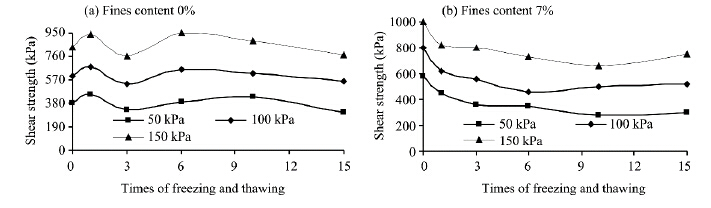

Figure 7 shows the shear strength vs. freeze-thaw cycles curves with different fines contents. As shown, when there were no fines in the CGS samples, the shear strength fluctuated up and down with increasing numbers of freeze-thaw cycles, which means that the effect of freezing-thawing on the CGS samples was not significant(Figure 7a).

|

| Figure 7 Curves of shear strength vs. freeze-thaw cycles |

With increasing increments of fines content(Figure 7b), the shear strength decreased exponentially as the fines content increased, and leveled off after the ninth freeze-thaw cycle. This was because the high frost susceptibility of the fines gradually took the dominant position with the increasing increment fines content, which changed the internal structures of the CGS samples(Konrad and Lemieux, 2005); with more freeze-thaw cycles, the effect of frost heave and thaw settlement gradually weakened, and the shear strength of the CGS samples leveled off.

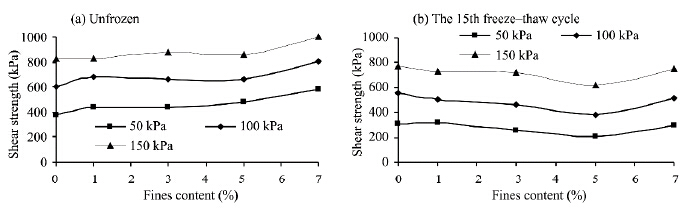

Figure 8 shows the shear strength vs. fines content curves under different numbers of freeze-thaw cycles. As shown in Figure 8a, in the unfrozen CGS samples the shear strength increased with the increasing increment of fines content, which means that a higher fines content effectively improved the bearing capacity of the CGS. However, in the frozen CGS samples, the shear strength decreased with the increasing increment of fines content because of the high frost susceptibility of the fines(Figure 8b).

|

| Figure 8 Curves of shear strength vs. fines content under different numbers of freeze-thaw cycles |

1)The factors of fines content and number of freeze-thaw cycles strongly impact the mechanical properties of CGS, which should not be ignored in the design and construction of railway subgrade coarse-grained soil fillings in frozen regions.

2)In this study, the frost heave ratio increased with the increasing increment of fines content. However, based on our compaction test results, we estimate that a reasonable fines content of 5%-7% can simultaneously achieve efficient compaction and weaker frost susceptibility.

3)When the fines content was less, the shear strength of the CGS samples was less affected by the number of freeze-thaw cycles. As the fines content increased, the shear strength decreased with the increase of freeze-thaw cycles and reached its steady state after the ninth freeze-thaw cycle.

4)In an unfrozen condition, the shear strength of the CGS samples increased with the increase of fines content. After being subjected to freeze-thaw cycles, the shear strength decreased as the fines content increased and reached its steady state when the fines content was between 5% and 7%.

5)Considering the effect of freezing-thawing and the fines content on the strength, deformation, and compaction of the CGS, as well as particle breakage caused in the compaction process, we recommend a reasonable fines content of 5% for railway subgrade CGS fillings in frozen regions. Also, the mechanical indexes of the ninth freeze-thaw cycle are also recommended for the engineering design values.

Acknowledgments: This research was supported by the National Key Technology Support Program of China(No. 2012BAG05B00), the National Natural Science Foundation of China(Nos. 51208320 and 51178281), and the Key Subject of China Railway Corporation(Nos. 2014G003-F and 2014G003-A).| Arenson LU, Sego DC, 2006. The effect of salinity on the freezing of coarse-grained sands. Canadian Geotechnical Journal, 43(3): 325-337. |

| Chai HJ, Chen QY, Kong XC, et al., 2004. Overview of soil-stone high embankment construction study. Rock and Soil Mechanics, 25(6):1005-1010. |

| Chen J, Luo Q, Chen Z, et al., 2011. Experimental research on physical and mechanical properties of gravelly soil filling the base course of the subgrade bed of passenger dedicated line. Journal of the China Railway Society, 33(7):91-97. |

| Chen X, Wang Y, 1989. Control of frost heave in geotechnical engineering. Proceedings of the Eighth International Conference on Offshore Mechanics and Arctic Engineering, March 19-23, 1989, The Hague, Netherlands.New York: American Society of Mechanical Engineers (ASME). |

| Chen XB, Zhang JS, Feng ZP, 2007. Experimental study on rheological engineering properties of coarsely granular red sandstone soil. Chinese Journal of Rock Mechanics and Engineering, 26(3):601-607. |

| Chu FY, Zhu JG, Jia H, et al., 2012. Experimental study of mechanical behaviour of coarse-grained soil in unloading and reloading. Rock and Soil Mechanics, 33(4):1061-1066. |

| Code for Design of High Speed Railway HSR subgrades (TB10621-2009), 2009.Beijing: China Railway Publishing House. |

| Jiang ZM, Wang W, Feng SR, et al., 2014. Experimental study on influence of stress on seepage failure characteristics of coarse grained soil with cohesive particles. Chinese Journal of Geotechnical Engineering, 36(1):98-104. |

| Jiang JQ, Yang GL, Li Y, et al., 2010. Strength and deformation characteristics of red-sandstone granular soil reinforced with gabion mesh. Chinese Journal of Geotechnical Engineering, 32(7):1079-1086. |

| Konrad JM, 2008. Freezing-induced water migration in compacted base-course materials. Canadian Geotechnical Journal,45(7):895-909. |

| Konrad JM, Lemieux N, 2005. Influence of fines on frost heave characteristics of a well-graded base-course material. Canadian Geotechnical Journal, 42(2): 515-527. |

| Lai Y, Zhang S, Yu W, 2012. A new structure to control frost boiling and frost heave of embankments in cold regions. Cold Regions Science and Technology, (79-80): 53-66. |

| Vinson TS, Ahmad F, Rieke R, 1986. Factors Important to the Development of Frost Heave Susceptibility Criteria for Coarse-Grained Soils. Washington D.C.: National Research Council (U.S.), Transportation Research Board.Transportation Research Record, pp.124-131. |

| Wang GJ, Yang CH, Zhang C, et al., 2009. Experimental research on particle breakage and strength characteristics of rock and soil materials with different coarse-grain contents. Rock and Soil Mechanics, 30(12):3649-3654. |

| Wang GJ, Yang CH, Zhang C, et al., 2011. Numerical simulation triaxial tests for coarse-grained soil and preliminary study of initial fabric of sample grain. Rock and Soil Mechanics, 32(2):585-592. |

| Xu M, Song EX, 2010. A strain hardening model for rockfills. Rock and Soil Mechanics, 31(9):2967-2973. |

| Xu J, Niu F, Niu Y, et al., 2011. Analysis on the effect of replacing-soil method on inhibiting frost heave of railway roadbed in seasonal frozen soil region. China Railway Science, 32(5):1-7. |

| Ye Y, Wang Z, Cheng A, et al., 2007. Frost heave classification of railway subgrade filling material and the design of anti-freezing layer. China Railway Science, 28(1):1-7. |

| Zhang SS, Yang XH, 2012. Large shear test on coarse saline soil with freeze-thaw cycle. Journal of Chang'an University (Natural Science Ed.), 32(3):11-16. |

| Zhang YC, Li X, Zhang XF, et al., 2007. Research on frost heave susceptibility and classification of coarse grained soil of highway subgrade in seasonally frozen ground region. Chinese Journal of Geotechnical Engineering, 29(10):1522-1526. |

| Zhu JG, Ji EY, Fang ZR, et al., 2013. Comparison of triaxial tests with Ko-consolidated and isotropically consolidated specimens of coarse grained soil. Journal of Disaster Prevention and Mitigation Engineering, 33(4):394-398. |

| Zhu JG, Wang YL, Jia H, et al., 2011. Experimental study on resilience behaviour of coarse grained soils. Chinese Journal of Geotechnical Engineering, 33(6):950-954. |

2015, 7

2015, 7