Article Information

- Lei Guo, QiHao Yu, XiaoNing Li, XinBin Wang, YongYu Yue. 2015.

- Refreezing of cast-in-place piles under various engineering conditions

- Sciences in Cold and Arid Regions, 7(4): 376-383

- http://dx.doi.org/10.3724/SP.J.1226.2015.00376

Article History

- Received: March 5, 2015

- Accepted: May 15, 2015

2. University of Chinese Academy of Sciences, Beijing 100049, China

1 Introduction

The permafrost on the Qinghai-Tibet Plateau(QTP)is warm and ice-rich, and thus its mechanical behavior is temperature-sensitive(Cheng and Ma, 2006). The warming of permafrost will result in the weakening of its bearing capacity and an increase in its compressibility. Hence, structures on ice-rich permafrost can settle and crack, which will threaten their operation(Wu et al.,2002; Mu et al.,2014). An effective engineering measure in warm and ice-rich permafrost is cast-in-place piles(CIPPs), which have been successfully used in construction of the Qinghai-Tibet Railway(QTR)(Wu et al.,2006) and the Qinghai-Tibet Power Transmission Line(QTPTL)(Wang et al.,2014).

Along with the Qinghai-Tibet Highway(QTH) and the QTR, the QTPTL is another key engineering accomplishment on the QTP. The structure traverses 550 km of permafrost regions, of which 147 km are warm and ice-rich regions which might threaten the stability of towers(Yu et al.,2013). In order to prevent settlement of the towers, large numbers of CIPPs were used on the QTPTL(Wang et al.,2014). However, a great amount of hydration heat is released after the casting of a CIPP, and this warms and melts the surrounding permafrost(Yuan et al.,2005; Li and Xu, 2008). The melting of the surrounding permafrost will result in the loss of adfreezing force or even an increase in negative friction in the ice-rich permafrost, and will lessen the stability of the towers(Xu, 2009).

Many researches have been done on the mechanism of hydration heat release and its thermal impact on surrounding permafrost(e.g., Ma and Wang, 2003; Zhang et al.,2004; Wu et al.,2006; Shi and Huang, 2009; Liu and Chen, 2010). However, there is still more work need to be done. In the construction of transmission lines in permafrost regions, in order to reduce the thermal disturbance of the construction process, construction is usually done in winter(Wang et al.,2014). However, whether this practice is most appropriate for the installation of CIPPs has not yet been confirmed. Also, there are no reports about the difference in thermal effects on the permafrost below and around CIPPs when the pile depths vary. And finally, there is lack of consensus among researchers as to whether or not the casting temperature of concrete could seriously impact the thermal regime of permafrost(Ma et al.,2005; Ding et al.,2011).

Given this lack of comprehensive research, using ANSYS software, the thermal effect of hydration heat of a CIPP to the surrounding permafrost under different engineering conditions were simulated. The acceptable variation of casting temperature for CIPPs in warm and ice-rich permafrost regions on the QTP is discussed here.

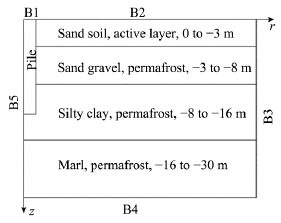

2 Simulation modelA CIPP is cylindrical in shape and is spatially axial-symmetrical, so our simulation model was built under a two-dimensional cylindrical coordinate system. As shown in Figure 1, the depth of the model was 30 m and the width was 10.5 m. The structure of this model was established according to the typical strata of the QTP(Zhang et al.,2006; Wen et al.,2007) and relevant drilling data. This model has been successfully used in past simulations of thermal interactions between tower foundations and surrounding permafrost, and achieved satisfactory results(Chen et al.,2013; Wen et al.,2013).

|

| Figure 1 Simulation model |

Heat transfer in the ground in a 2-D cylindrical model is controlled by:

| $\rho c\frac{{\partial T}}{{\partial t}} = \frac{1}{r}\frac{\partial }{{\partial r}}(\lambda r\frac{{\partial T}}{{\partial r}}) + \frac{\partial }{{\partial z}}(\lambda \frac{{\partial T}}{{\partial z}}) + \dot \emptyset $ | (1) |

| $c = \left\{ \begin{array}{l} {c_f}\quad \quad \quad \quad \quad \quad (T &1t; {T_m} - \Delta T)\\ \frac{L}{{2\Delta T}} + \frac{{{c_f} + {c_u}}}{2}\quad \;({T_m} - \Delta T \le T \le {T_m} + \Delta T)\\ {c_u}\quad \quad \quad \quad \quad \quad (T > {T_m} + \Delta T) \end{array} \right.$ | (2) |

| $\lambda = \left\{ \begin{array}{l} {\lambda _f}\quad \quad \quad \quad \quad \quad \quad \quad \quad \quad \quad \;(T &1t; {T_m} - \Delta T)\\ {\lambda _f} + \frac{{{\lambda _u} - {\lambda _f}}}{{2\Delta T}}\left[ {T - \left( {{T_m} - \Delta T} \right)} \right]\;\;\,\;({T_m} - \Delta T \le T \le {T_m} + \Delta T)\\ {\lambda _u}\quad \quad \quad \quad \quad \quad \quad \quad \quad \quad \quad \;(T > {T_m} + \Delta T) \end{array} \right.$ | (3) |

There are several hypothetical models related to the release of hydration heat of cement(He and He, 2010); we used the exponential model, which has been widely applied(Jia et al.,2003; Chen et al.,2014):

| $Q = {Q_0}\left( {1 - {e^{ - mt}}} \right)$ | (4) |

| Casting temperature(°C) | 5 | 10 | 15 | 20 | 25 | 30 |

| M(d−1) | 0.295 | 0.318 | 0.340 | 0.362 | 0.384 | 0.406 |

| Source: He and He, 2010. | ||||||

The heat generation of concrete can be written as(Liu and Chen, 2010):

| $\theta (t) = (W + kF)\frac{{\partial Q}}{{\partial t}} = (W + kF)m{Q_0}{e^{ - mt}}$ | (5) |

The thermal boundaries were taken as follows: Boundary 1, 2:

| $T = {T_0} + A{\rm{sin}}(\frac{{2{\rm{\pi }}t}}{{8760}} + k{\rm{\pi }}) + \alpha \cdot t$ | (6) |

Boundary 3, 5:

| $\;\;\frac{{\partial T\left( {x,y,t} \right)}}{{\partial x}} = 0$ | (7) |

Boundary 4:

| $\;\;\frac{{\partial T\left( {x,y,t} \right)}}{{\partial y}} = 0.01$ | (8) |

| Parameter | Boundary 1 | Boundary 2 |

| T0(°C) | 1.0 | −0.3 |

| A(°C) | 11.6 | 9.6 |

| Soil type | Depth(m) | Dry density(kg/m3) | Thermal conductivity, λ(J/(h·m·K)) | Volumetric heat capacity, C(J/(m·K)) | |||

| Frozen | Unfrozen | Frozen | Unfrozen | ||||

| S and y soil | 0 to −3 | 1, 800 | 3, 222 | 2, 790 | 852 | 934 | |

| S and gravel | −3 to −8 | 1, 900 | 7, 308 | 5, 544 | 781 | 972 | |

| Silty clay | −8 to −16 | 1, 800 | 8, 352 | 6, 480 | 1, 358 | 1, 762 | |

| Marl | −16 to −30 | 1, 800 | 6, 552 | 5, 760 | 981 | 1, 272 | |

| Concrete | -- | 2, 500 | 10, 584 | 10, 584 | 950 | 950 | |

| Source: Xu et al.,2010. | |||||||

In the first step of the simulation, the nodes of different depths in the simulation domain were given different initial temperatures according to the monitored temperatures in a typical warm and ice-rich permafrost region. Then the boundary conditions shown in Equations (6)-(8) were incorporated into the model to calculate the initial condition, without considering global warming and the thermal effect of the tower foundation. The initial condition was considered to have been achieved when the temperature changes of all the nodes in the model were all less than 0.01 °C/a.

In the second step, the calculated initial temperatures of different times were applied to the model according to our calculation cases. Then the casting temperature was applied to the pile and the boundaries shown in Equations (6)-(8) were applied to the boundaries. After that, the numerical simulation was begun.

3 Results and discussion 3.1 Casting seasonThe CIPPs of the QTPTL were designed considering the adfreezing force between the piles and the surrounding permafrost, so it is important for the stability of a tower whether the soil around the pile is frozen or not. In open-excavated foundations, the construction process will induce the warming and mechanical weakening of sub-base permafrost because of the dramatic thermal effects of heat advection and radiation. In ice-rich permafrost regions, this mechanical weakening will be dramatic and might cause settlement of the towers. As a result, considering the influence of thawing permafrost, wetl and water accumulation, and ground surface conditions for construction vehicles, QTPTL construction in permafrost regions was undertaken in winter(Wang et al.,2014). However, the seasonal change of the thermal effect of construction of CIPPs is weak because the pile diameters are small with respect to their depth, so the excuse is insufficient that the construction of CIPPs in permafrost regions should be conducted in winter. If CIPPs can be constructed in warm seasons, the engineering schedule will be much shorter and the expense much less. Therefore, in this paper, we simulated the refreezing process of a CIPP cast in different seasons to elucidate the effect of the construction season.

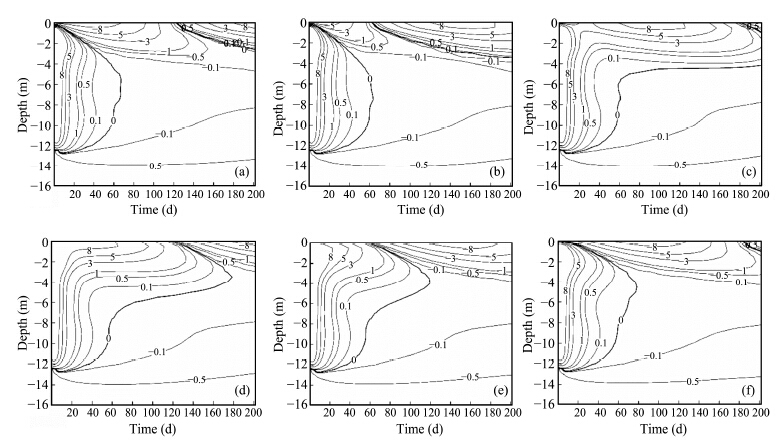

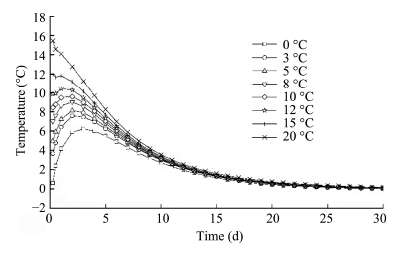

Figure 2 illustrates the refreezing processes of the side walls of CIPPs cast in different seasons. The temperature change process of the sides of the CIPPs varied obviously with the change of casting season. However, the variation mainly occurred within a depth of 6 m. The temperature change processes below 6 m were generally the same in the different casting seasons. Sixty days after being cast, CIPPs below 6 m in depth can be frozen regardless of when they were cast.

|

| Figure 2 The refreezing process of the sides of piles cast in different seasons(Unit: °C). Casting time:(a)January 1;(b)March 1;(c)May 1;(d)July 1;(e)September 1;(f)November 1 |

The bearing capacity of a CIPP in permafrost regions is dramatically affected by the permafrost temperature around the pile, and the pile stability increases with lowering temperature(Xu et al.,2007), especially when the thermal state of high-moisture-content soils changes from unfrozen to frozen(Ding et al.,2011).

Many studies have shown that the main threat to the stability of CIPPs in permafrost regions is frost jacking(e.g., Lyazgin et al.,2004; Jiang and Liu, 2006; Grigor'ev et al.,2012). The side refreezing process of piles cast on January 1(Figure 2a) and July 1(Figure 2d)were compared to evaluate the anti-jacking ability of CIPPs cast in different seasons. In both cases the pile side below 2 m was unfrozen 30 d after the pile was cast.

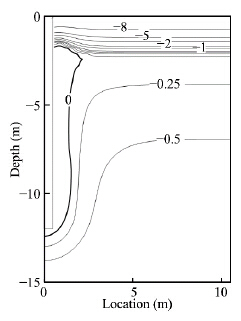

After 30 d, the frost depth was about 2 m for the pile cast on January 1. The temperature field around the pile(Figure 3)shows that because of the high heat conductivity of concrete, the frost depth of the pile side was 0.2 m deeper than that of soil 0.5 m away from the pile side. According to the uneven migration law of unfrozen water, the unfrozen water will migrate to the pile side and freezing will occur(He, 2013). This will raise the tangential frost heave force, which will be quite intensive in moisture-rich soils. The tangential frost heave force increases with the ongoing freezing process, and might result in pile breakage before its critical strength is achieved. At the same time, because the whole pile below 2 m was unfrozen when the frost depth reached 2 m, the pile might be jacked up if the depth of the pile was shallow.

|

| Figure 3 Temperature field on January 31 around the pile cast on January 1(Unit: °C) |

For the pile cast on July 1(Figure 2d), most of the pile had been frozen when the tangential frost heave force appeared. At that time, the appearance and increase in adfreezing force would dramatically increase the anti-jacking ability of the pile as well as improve the tower stability.

The above analysis demonstrates that a pile cast in any season could be frozen after a whole cold season. Considering that the CIPPs might be break or jacking up due to the freezing of piles in the early stages, warm seasons(from April to September)are the most favorable casting seasons. The actual casting time should be determined according to the moisture conditions of the ground surface.

3.2 Buried depthThe buried depth of a CIPP might vary with different engineering conditions. For areas with high-bearing-capacity permafrost, the depth of a CIPP can be relatively shallow, and vice versa. However, the deeper the pile, the more cement will be used and the more hydration heat will be released. We therefore simulated the effect of increasing hydration heat on the thermal state of a CIPP.

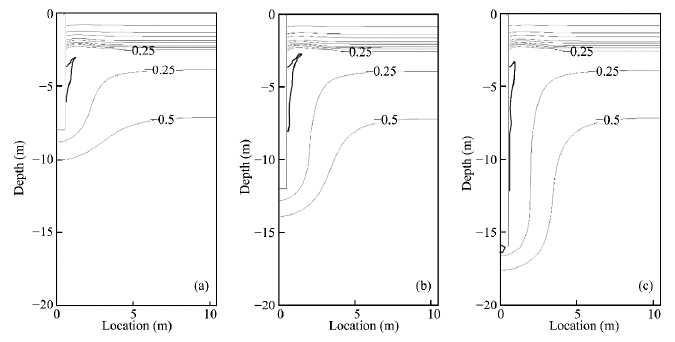

Figure 4 is the temperature field around CIPPs 60 d after they were cast, the depths of which were 8 m, 12 m, and 16 m. The thermal disturbance mainly increased vertically with the deepening of the pile, and there was little change in the lateral direction. The duration of the refreezing process and thermal effect were generally the same for CIPPs with different depths. Because the ice content of soil on the QTP below the depth of 8 m is generally low, the vertical extension of the thermal effect will slightly impact the stability of a CIPP. At the same time, increasing the CIPP depth can enhance its anti-jacking and anti-settlement ability.

|

| Figure 4 Temperature fields around CIPPs 60 d after they were cast with depths of(a)8 m, (b)12 m, and (c)16 m(Unit: °C) |

Therefore, longer CIPP lengths are good for tower stability, but this will result in increased engineering duration and expense, so a suitable CIPP depth should be chosen according to its capacity requirement.

3.3 Casting temperatureIn order to construct a qualified CIPP, the casting temperature should be positive and the pile should not be frozen soon after casting(Ding et al.,2011). The higher the casting temperature, the better the mechanical behavior of the CIPP. However, three problems make it difficult to cast a pile on the QTP. First, the air temperature on the QTP is quite low, especially in winter. Increasing the casting temperature will result in a larger consumption of energy and longer construction duration. Second, if the casting temperature is too high, the refreezing might be difficult. Third, as mentioned earlier, researchers still disagree on whether the casting temperature significantly affects the thermal disturbance(Ma et al.,2005; Ding et al.,2011; Chen et al.,2014).

Therefore, it is valuable to study the influence of casting temperature and the suitable casting temperature ranges. There have been many studies on suitable casting temperature ranges in permafrost regions(e.g., Jia et al.,2003; Ma et al.,2005; Chen et al.,2014). Most of their recommendations were based on engineering experiences, except for Chen et al.(2014)who produced calculation results based on open-excavated footings. However, the thermal effect of a CIPP is different from that of an open-excavated footing, and thus the optimal casting temperature should be different. We therefore simulated the thermal effects of CIPPs under different casting temperatures to study the influence of casting temperature on the thermal disturbance and determine the optimal casting temperature range.

After the casting, the temperature change process varies at different locations on a CIPP. At the pile base the refreezing duration is shortest and the increase of the pile mechanical strength is slowest, so we chose that area to study the influence of casting temperature. Figure 5 shows the temperature change process of a CIPP base under different casting temperatures: the pile base was still unfrozen 30 d after the pile was cast, which means the CIPP could reach its critical mechanical strength against freezing before it was refrozen. Then the strength could continue to increase even if the pile was frozen(Ding et al.,2011). Therefore, it can be concluded from Figure 5 that the design strength of a CIPP can be achieved under any positive casting temperature. However, when the casting temperature is close to 0 °C, some of the cement will not be hydrated, and the hydration heat and its heat generation rate should be much less than the calculation results of Equations (4) and (5). Under such conditions, the mechanical strength of the CIPP will be significantly lowered. Therefore, the casting temperature should be much higher than the refreezing point, and we suggest that a casting temperature higher than 2 °C is reasonable.

|

| Figure 5 Temperature change process at the CIPP base under different casting temperatures(30-day duration) |

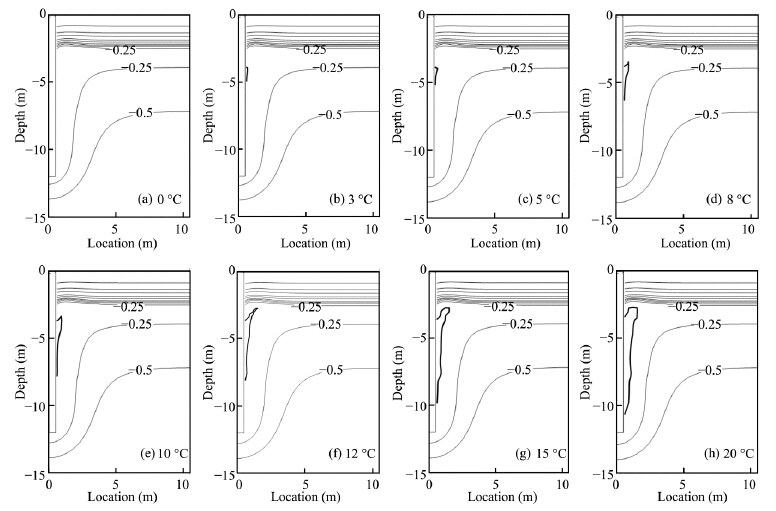

Figure 6 shows the temperature field around CIPPs 60 days after they were cast under different casting temperatures.

|

| Figure 6 Temperature fields around CIPPs 60 d after casting under different casting temperatures(Unit: °C) |

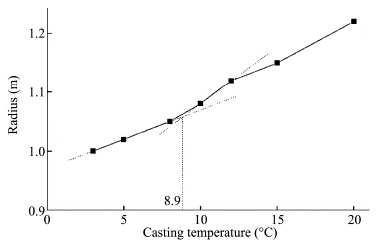

Figure 7 shows the relationship between casting temperature and the radius of the melting circle. It can be seen that the casting temperature seriously impacts the thermal effect. As the casting temperature rises, the radius of the melting circle increases and the refreezing process extends. When the casting temperature is lower than 8.9 °C, the radius enlarges linearly with the increasing casting temperature. Thus, in order to control the melting circle, the casting temperature should not be higher than 9 °C.

|

| Figure 7 The relationship between casting temperature and the radius of the melting circle |

1)The casting temperature mainly impacts the refreezing process within the first 6 m of CIPP depth. Without considering the ground surface conditions, construction in summer is a better choice for enhancing the stability of a CIPP. Casting in summer can also avoid engineering problems such as breaking and jacking before the designed mechanical strength of the pile is achieved and the adfreezing force is developed.

2)With the increase of pile depth, the thermal effect of a CIPP on the surrounding soil mainly exp and s vertically, and the lateral heat disturbance changes little. The deeper a pile, the better its stability, but increasing pile depth will result in a dramatic increase in engineering duration and expense.

3)Casting temperature clearly impacts the temperature change process and the melting circle. As the casting temperature rises, the radius of the melting circle increases and the duration of refreezing and heat effect exp and s. For CIPPs installed in permafrost regions on the QTP, the optimal casting temperature range should be between 2 °C and 9 °C.

Acknowledgments: The authors would like to thank the editor and the reviewer who helped in improving this paper. The project was supported by the National Key Basic Research Program of China(973 Program)(No. 2012CB026106), the National Natural Science Foundation of China(Grant No. 41171059), and the Fund of the State Key Laboratory of Frozen Soil Engineering(No. SKLFSE-ZY-16).| Chen ZY, Li GY, Mu YH, et al., 2014. Impact of molding temperature and hydration heat of concrete on thermal properties of pile foundation in permafrost regions along the Qinghai-Tibet DC Interconnection Project. Journal of Glaciology and Geocryology, 36(4): 818-827.DOI:10.7522/j.issn.1000-0240.2014.0098. |

| Chen ZY, Li GY, Yu QH, et al., 2013.Study of the thermal stability of cast-in-place pile foundations of the Qinghai-Tibet DC Transmission Project in permafrost regions. Journal of Glaciology and Geocryology, 35(5): 1209-1218.DOI:10.7522/j.issn.1000-0240.2013.0136. |

| Cheng GD, Ma W, 2006. Frozen soil engineering problems in construction of the Qinghai-Tibet Railway. Chinese Journal of Nature, 28(6): 315-320. |

| Ding JK, Han LW, Xu BK, et al.,2011. Permafrost and Railways. Beijing: China Railway Publishing House. |

| Grigor'ev VS, Ol'shanskii VG, Starostenkov AD, et al., 2012.Experience in 110-500 kV overhead transmission line construction and renovation projects. Power Technology and Engineering, 46(4): 317-320. |

| He F, 2013. Experimental Research on Regular Patterns of Water Migration and Mechanism of the Formation of Ice Films between Different Mediums in Freezing Silty Clay. M.S. Thesis, Lanzhou Jiaotong University, Lanzhou, China. |

| He JH, He JH, 2010. Study on the calculation method of the hydrate heat and adiabatic temperature rise of concrete. Science and Technology Information, 21:465-466. |

| Jia XY, LiWJ, ZhuYQ, 2003. Analysis on hydration influence of grouting pile concrete in permafrost regions. Journal of Shijiazhuang Railway Institute, 16(4): 88-90. |

| Jiang HP, Liu ZR, 2006. ±500 kV direct current transmission line ground and foundation design in frozen earth area. Inner Mongolia Electric Power, 24(4):1-4. |

| Li N, Xu B, 2008. A new type of pile used in frozen soil foundation. Cold Regions Science and Technology, 53(3): 355-368. DOI:10.1016/j.coldregions.2007.10.005. |

| Liu J, Chen B, 2010. Numerical simulation on the temperature of massive concrete. China Concrete and Cement Products, (5):15-27. |

| Lyazgin AV, Lyashenko VS, Ostroborodov SV, et al., 2004. Experience in the prevention of frost heave of pile foundations of transmission towers under northern conditions. Power Technology and Engineering, 38(2): 124-126. |

| Ma BG, Wang YF, 2003. Research on thermal effect to frozen earth ground work produced by concrete engineering. Low Temperature Architecture Technology, (1):4-7. |

| Ma H, Liao XP, Lai YM, 2005. Temperature control problem of concrete of pile foundation under construction in the permafrost regions of the Qinghai-Tibet Railway. Journal of Glaciology and Geocryology, 27(2): 176-181. |

| Mu YH, Ma W, Niu FJ, 2014. Study on geotechnical hazards to roadway engineering in permafrost regions. Journal of Disaster Prevention and Mitigation Engineering, 34(3):259-267. |

| Qin DH, Ding YH, Wang SW, et al., 2002. A study of environment change and its impacts in western China. Earth Science Frontiers, 9(2): 321-328. |

| Shi HS, Huang XY, 2009. Study process on the hydration heat of Portland cement. Cement, (12):4-10. |

| Wang GS, Yu QH, You YH, et al., 2014. Problems and countermeasures in construction of transmission line projects in permafrost regions. Sciences in Cold and Arid Regions, 6(5): 432-439. DOI: 10.3724/SP.J.1226.2014.00432. |

| Wen Z, Sheng Y, Ma W, et al., 2007. Study on deformation characters of railway insulated embankment in permafrost regions. Journal of Rock Mechanics and Engineering, 187(8):1670-1677. |

| Wen Z,Yu QH, Li GY,et al., 2013. Stresses and deformations of a tower foundation subject to frost action in permafrost regions. In: Leung CF, Goh SH, Shen RF (eds.). Advances in Geotechnical Infrastructure. Singapore: Research Publishing Services, pp. 835-840. DOI:10.3850/978-981-07-4948-4_022. |

| Wu QB, Liu YZ, Zhang JM, et al., 2002. A review of recent frozen soil engineering in permafrost regions along Qinghai-Tibet Highway, China. Permafrost and Periglacial Processes, 13(3): 199-205. DOI: 10.1002/ppp.420. |

| Wu YP, Su Q, Guo CX, et al., 2006. Nonlinear analysis of ground refreezing process for pile group bridge foundation in permafrost. China Civil Engineering Journal, 39(2):78-84. |

| Xu CH, 2009. Research on axial bearing behavior of cast-in-place concrete piles in permafrost regions. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China. |

| Xu CH, Xu XY, Qiu MG, et al., 2007. Numerical analysis of adfreezing force of engineering pile in permafrost. Journal of Harbin Institute of Technology, 39(4):542-545. |

| Xu XZ, Wang JC, Zhang LX, et al., 2010. Physics of Frozen Soil. Beijing: Science Press. |

| Yu QH, You YH, Ding YS, et al., 2013. Analysis of heat transfer characteristics of frozen soil foundation in Qinghai-Tibet DC Transmission Line Project. Chinese Journal of Rock Mechanics and Engineering, 32(S2): 4025-4031. |

| Yuan XZ, Ma W, Liu YZ, 2005. Study on thermal regime of high-temperature frozen soil during construction of cast-in-place pile. Chinese Journal of Rock Mechanics and Engineering, 24(6):1052-1055. |

| Zhang MY, Lai YM, Gao ZH, et al., 2006. Influence of boundary conditions on the cooling effect of crushed-rock embankment in permafrost regions of Qinghai-Tibetan Plateau. Cold Regions Science and Technology, 44(3): 225-239. DOI:10.1016/j.coldregions.2005.12.002. |

| Zhang XF, Lai YM, Yu WB, et al., 2004. Numerical analysis for the hydration heat of cast-in-situ concrete foundations of culverts on the Qinghai-Tibet Railway. Journal of Glaciology and Geocryology, 26(1):106-111. |

2015, 7

2015, 7