Article Information

- ZhenYa Liu, JingYu Liu, QingZhi Wang, JianKun Liu. 2015.

- Compressive strength and frost heave resistance of different types of semi-rigid base materials after freeze-thaw cycles

- Sciences in Cold and Arid Regions, 7(4): 365-369

- http://dx.doi.org/10.3724/SP.J.1226.2015.00365

Article History

- Received: March 8, 2015

- Accepted: May 22, 2015

1 Introduction

The semi-rigid base, which is typical of Chinese roadway construction, relies on materials that are economical and easy to acquire, and have high strength. Most of the highways in China are built of cement-stabilized or lime-fly ash-stabilized semi-rigid bases(Mao and Zhi, 2003), but they are often adversely affected by low temperatures during construction, which may cause low early strength and delay the start of highway use(Zhao, 2013). Frost insulation measures should be implemented if the construction must be done in winter, which may limit the application of semi-rigid bases to a certain extent(Ma et al.,1999).

Semi-rigid road bases in northern China are often subject to damage involving ice, water, and aggregates under wet and low-temperature conditions(Wang et al.,2008). There is a 9% volume expansion when water is changed to ice, and the uneven distribution of frost heave stress can easily cause premature damage to a semi-rigid base, which will shorten the life of the road(Gray et al.,1994). Frost heave is a common disease of semi-rigid bases, especially with the increase of traffic and frequent changes of extreme weather, which are severe challenges for semi-rigid bases. How to improve the anti-frost heave performance of this kind of base has become an urgent problem. Frost heaves of semi-rigid bases are mainly related to the water supply, the different materials content, and the grade of gravel(Wang et al.,2006). Therefore, in this study, frost heave experiments and compressive strength tests were conducted by changing the contents of different materials and subjecting them to freeze-thaw cycles.

2 Materials and experiments designCement and lime-fly ash are two stabilization materials that are commonly used in semi-rigid bases. Gravel and sand are largely used for the basic materials of such bases because they are inexpensive and easy to acquire. The four kinds of resulting semi-rigid bases are lime-fly ash-stabilized gravel, lime-fly ash-stabilized sand, cement-stabilized gravel, and cement-stabilized sand. This paper discusses how varying the proportions of the materials affects the frost resistance and compressive strength of these semi-rigid bases after freeze-thaw cycles.

All the materials were chosen according to the Specifications for Design of Highway Asphalt Pavement(JTG D50-2006, 2007), which is formulated by the Chinese Ministry of Transportation. The basic physical properties of these materials are shown in Tables 1 to 4.

| Index | Value |

| Fitness(0.045 mm square sieve, %) | 10 |

| Water requirement ratio(%) | 89 |

| Loss on ignition(%) | 3.23 |

| Density(g/cm3) | 1.99 |

| Level | Stability | Compressive strength(MPa) | Flexural strength(MPa) | Setting time(d) | |||||

| 7 days | 28 days | 7 days | 28 days | Initial setting | Final setting | ||||

| P.O32.5R | Qualified | 17.9 | 34.26 | 3.14 | 5.32 | 80 | 252 | ||

| Uniformity coefficient | Fineness modulus | Apparent density(g/cm3) | Clay content(%) |

| 2.54 | 2.55-2.98 | 2.66-2.79 | 0.3-0.5 |

| Place of origin | Apparent density(g/cm3) | Crushing value(%) | Flakiness(%) | Clay content(%) |

| Gongyi | 2.62 | 9.63 | 4.23 | 0.3 |

Different proportions of cement, 4%, 6%, 8%, and 10%, were used to make test samples to determine how cement affects the frost resistance; different proportions of fly ash, 18%, 16%, 14%, and 12%, were also used.

The frost heave of the semi-rigid bases were tested by using a temperature-controlled, closed-system triaxial volume deformation apparatus, shown in Figure 1. A rubber membrane was installed on the completed samples in order to isolate water from the inner shaft, which was then filled with coolant to simulate the condition of confining pressure. Then the apparatus was put into a freezer set to −10 °C for 24 hours, and then the samples were thawed at room temperature for 24 hours.

|

| Figure 1 Triaxial volume deformation apparatus |

The compressive strength tests were conducted according to Test Method of Long-term Performance and Durability of Ordinary Concrete(GB/T50082-2009, 2010)which is a Chinese st and ard of road design; the samples were tested after 7 and 28 days of st and ard curing. The test results were recorded after the fifth and tenth freeze-thaw cycles.

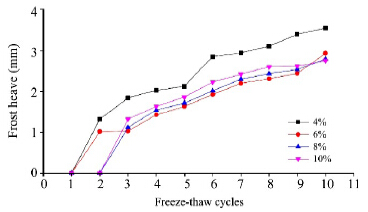

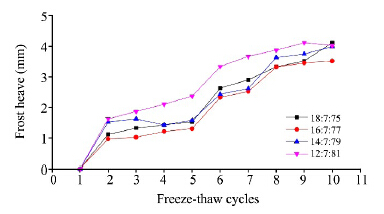

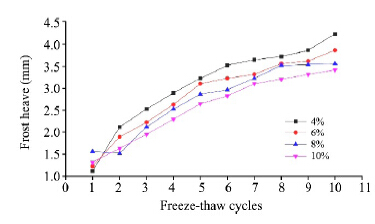

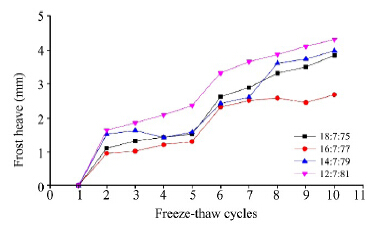

2.2 Experiment analysisThe relationship between frost heave and freeze-thaw cycles of the four kinds of semi-rigid bases are shown in Figures 2 to 5, after the triaxial volume deformation tests. The figures show that the frost heave volume decreased when the cement or the fly-ash amount was increased, while it increased with the number of freeze-thaw cycles(Zhang and Ruben, 2008). There was no significant difference in frost heave volume in the four different semi-rigid bases.

|

| Figure 2 Relationship between frost heave and freeze-thaw cycles of cement-stabilized sand |

|

| Figure 3 Relationship between frost heave and freeze-thaw cycles of lime-fly ash-stabilized sand (fly ash: lime: sand ) |

|

| Figure 4 Relationship between frost heave and freeze-thaw cycles of cement-stabilized gravel |

|

| Figure 5 Relationship between frost heave and freeze-thaw cycles of lime-fly ash-stabilized gravel(fly ash: lime: gravel) |

The amount of lime was maintained at 7%(Figures 3 and 5), while the fly ash content was varied from 12% to 18% because the content of the lime had little effect on frost heave during the freeze-thaw cycles(Boominathan and Hari, 2002). Figures 2 and 5 show that there was no significant difference in frost heave volume by varying the amount of fly ash from 14% to 18%, but the frost heave volume was greater when the amount of fly ash was 12%. Therefore, for frost resistance the optimal amount of fly ash was 14%. Figures 2 and 4 show that there was no significant difference in frost heave volume when the amount of cement varied from 6% to 10%. Therefore, the optimal amount of cement was 6%.

Figures 3 and 5 show that the frost heave volume suddenly increased greatly after the sixth freeze-thaw cycle. This was because in the first five freeze-thaw cycles there was certain bond strength between the fine particles, which gave the samples a high density and prevented moisture intrusion(Yi, 1995). However, when the number of freeze-thaw cycles increased, the bond strength between the particles was destroyed by the moisture intrusion(Penner, 1959) and the frost heave volume then increased quickly(Cross and Faber, 1995).

The compressive strength of the four different types of semi-rigid bases(32 samples)was tested before and after freeze-thaw cycles and after 7 and 28 days of curing, while 16 samples were tested after 28 days of curing, as a comparison. The samples that had 7 days of curing were put into the triaxial volume deformation apparatus for five freeze-thaw cycles and then the compressive strength was tested at room temperature. The samples that had 28 days of curing were put into the apparatus for 10 freeze-thaw cycles and then the compressive strength was tested at room temperature. The compressive strength test results are given in Tables 5 to 8.

| Test samples | Before freeze-thaw | After freeze-thaw | |||

| 7 d(MPa) | 28 d(MPa) | 7 d /5 cycles(MPa) | 28 d /10 cycles(MPa) | ||

| 4% cement added | 1.92 | 2.62 | 2.45 | 2.23 | |

| 6% cement added | 2.36 | 3.22 | 2.91 | 2.76 | |

| 8% cement added | 2.68 | 3.12 | 2.85 | 2.36 | |

| 10% cement added | 2.86 | 3.23 | 2.96 | 2.56 | |

| Test samples | Before freeze-thaw | After freeze-thaw | |||

| 7 d(MPa) | 28 d(MPa) | 7 d/5 cycles(MPa) | 28 d/10 cycles(MPa) | ||

| 4% cement added | 2.48 | 3.12 | 2.22 | 1.76 | |

| 6% cement added | 2.65 | 3.36 | 2.34 | 2.23 | |

| 8% cement added | 2.78 | 3.55 | 2.42 | 2.31 | |

| 10% cement added | 2.90 | 3.62 | 2.53 | 2.41 | |

| Test samples(fly ash: lime: sand ) | Before freeze-thaw | After freeze-thaw | |||

| 7 d(MPa) | 28 d(MPa) | 7 d/5 cycles(MPa) | 28 d/10 cycles(MPa) | ||

| 18:7:75 | 1.23 | 3.42 | 0.52 | 2.92 | |

| 16:7:77 | 1.33 | 3.22 | 0.68 | 2.73 | |

| 14:7:79 | 1.12 | 3.01 | 0.53 | 2.86 | |

| 12:7:81 | 1.03 | 2.86 | 0.42 | 2.53 | |

| Test samples(fly ash: lime: gravel) | Before freeze-thaw | After freeze-thaw | |||

| 7 d(MPa) | 28 d(MPa) | 7 d/5 cycles(MPa) | 28 d/10 cycles(MPa) | ||

| 18:7:75 | 1.53 | 3.66 | 0.73 | 3.21 | |

| 16:7:77 | 1.33 | 3.43 | 0.62 | 3.11 | |

| 14:7:79 | 1.22 | 3.23 | 0.64 | 3.02 | |

| 12:7:81 | 1.12 | 2.99 | 0.56 | 2.76 | |

Tables 5 and 7 show that the initial compressive strength of the lime-fly ash-stabilized materials was lowest, about 1.2 MPa, and it increased when more fly-ash was added. The compressive strength after five freeze-thaw cycles and 7 days of curing was also quite low. So, whatever the addition of fly ash and lime is, it's necessary to take measures to prevent the early damage. Therefore, it is important to enhance the initial strength of the lime-fly ash-stabilized base(Li and Zhou, 2007). In contrast, the compressive strength after 10 freeze-thaw cycles and 28 days of curing was almost as good as before the freeze-thaw cycles, which means there is no need for further protection for fly-ash and lime stabilized semi-rigid base after construction(Xie et al.,2006).

Tables 6 and 8 show that the cement-stabilized materials with 7 days of curing had high early compressive strength, which is good for frost resistance. However, the cement-stabilized materials that had 28 days of curing and 10 freeze-thaw cycles had a lower setting strength, which means winter construction using a cement-stabilized base can be carried out without the need for additional protective measures(Horiuchia et al.,2000).

Tables 5 to 8 show that the strength of fly ash-lime-stabilized materials was higher than the cement-stabilized materials after 28 days of curing and 10 freeze-thaw cycles. This is because the increased hydration content further reduces the internal porosity and sometimes even eliminates it; as the hydration content increases, so does the strength(Simonsen et al.,2001). These factors cause the frost resistance of fly ash-lime-stabilized material to increase with the curing age. In contrast, the frost resistance of cement-stabilized materials does not increase rapidly, largely because of its lack of bonding materials and its greater porosity. Although cement-stabilized materials have a good early strength, their frost resistance cannot be prolonged as the curing age increases. Therefore, it is better to construct roadways with semi-rigid bases in the summers in cold regions, and it is necessary to increase the early strength of fly ash-lime-stabilized bases.

3 Conclusions1)Adding more cement can achieve a higher compressive strength and good frost resistance ability. Thus, a cement-stabilized base can have a larger proportion of cement for construction in cold regions. There is no significant strength difference when the cement amount varies from 6% to 10%, but the cement content of 4% has significantly lower strength. Another factor is that the cement can also cause reflection cracks in the pavement due to temperature shrinkage cracks in the cement(Ruth, 1985). Our results here indicate that the optimal amount of cement is 6%, and the optimal amount of fly ash is 14%.

2)The early compressive strength of a cement-stabilized base is almost the same as after five freeze-thaw cycles, but the compressive strength decreases after 10 freeze-thaw cycles. Therefore, frost-resistance methods should be considered for the roadway service period but they are not necessary during the construction time.

3)A fly ash-lime-stabilized base lacks early strength and early frost-resistance ability, so it is necessary to use some methods or materials to improve the early strength of this kind of base during construction. The frost heave of a fly ash-lime-stabilized base will suddenly increase after five or six freeze-thaw cycles, which may affect the stability of the road. For this material, it is better to construct in the summer or choose a cement-stabilized semi-rigid base.

Acknowledgments: The research was supported by the National Natural Science Foundation of China(Nos. 51378057 and 41371081).| BoominathanA,Hari S, 2002. Liquefaction strength of fly ash reinforced with randomly distributed fibers. Soil Dynamics and Earthquake Engineering, 22(9-12):1027-1033.DOI:10.1016/S0267-7261(02)00127-6. |

| Cross SA, Faber CZ, 1995. Fly ash in cold recycled bituminous pavement. Transportation Research Record, No. 1486. Washington D.C.: Transportation Record Board, pp. 49-56. |

| GB/T50082-2009, 2010. Test Method of Long-Term Performance and Durability of Ordinary Concrete. Beijing: China Architecture & Building Press. |

| Gray DH, Tons E, Thiruvengadam TR, 1994. Performance evaluation of a cement-stabilized fly ash base. Transportation Research Record, No. 1440. Washington D.C.: Transportation Research Board, pp. 8-15. |

| Horiuchia S, KawaguchiM, YasuharaK, 2000.Effective use of fly ash slurry as fill material. Journal of Hazardous Materials, 76(2-3): 301-337.DOI:10.1016/S0304-3894(00)00205-3. |

| JTG D50-2006, 2007.Specifications for Design of Highway Asphalt Pavement. Beijing: Ministry of Transport of the People's Republic of China. |

| Li BX, Zhou MK, 2007. Effect of quarry waste powder in limestone manufactured sand as mineral admixture on workability and strength of concretes. Highway, 12: 142-145. |

| MaW, Xu XZ, Zhang LX, 1999. Influence of frost and thaw cycles on shear strength of lime silt. Chinese Journal of Geotechnical Engineering, 21(2): 23-25. |

| Mao XS, Zhi XL, 2003. Checking method of construction deflection of semi-rigid base. Journal of Chang'an University (Natural Science Edition),23(2):37-40.DOI:10.3321/j.issn:1671-8879.2003.02.009. |

| Penner E, 1959. The mechanism of frost heave in soils. Highway Research Board Bulletin, 221(D): 1-22. |

| Ruth BE, 1985. Evaluation and prevention of water damage to asphalt pavement materials, STP 899. Philadelphia: American Society for Testing and Materials (ASTM), pp. 109-113. |

| Simonsen E, IsacssonU, 2001. Soil behavior during freezing and thawing using variable and confining pressure triaxial tests. Canadian Geotechnical Journal, 38(4): 863-875. DOI:10.1139/t01-007. |

| Wang SJ, ChenJB, Huang XM, 2006. Study on ground temperature characteristics of embankment berm on permafrost. Chinese Journal of Rock Mechanics and Engineering, 25(1): 146-151.DOI:10.3321/j.issn:1000-6915.2006.01.024. |

| WangZ, Shi CJ, Qian JS, et al., 2008. Properties of concrete with surface treated lightweight aggregate. Journal of the Chinese Ceramic Society, 36(1): 54-60.DOI:10.14062/j.issn.0454-5648.2008.01.027. |

| Xie HQ, He C, Li YL, 2006. Study on insulating layer thickness by phase-change temperature field of highway tunnel in cold region. Chinese Journal of Rock Mechanics and Engineering, 26(s2): 4395-4401. |

| Yi L, 1995. Resilient modulus of fly ash stabilized aggregates. M.S. thesis, University of Oklahoma, Norman, U.K., pp.120-136. |

| Zhang J, Ruben S, 2008. Fly-Ash-Stabilized Gypsiferous Soil as an Embankment Material. Berlin: Springer Berlin Heidelberg Press, pp. 32-34. |

| Zhao YG, 2013. Study on frost resistance performance of semi-rigid base material and construction control. M.S. thesis, Chang'an University, Xi'an, Shaanxi, China, pp. 36. |

2015, 7

2015, 7