Article Information

- Svyatoslav Ya. Lutskiy, Taisia V. Shepitko, Alexander M. Cherkasov. 2015.

- Technological monitoring of subgrade construction on high-temperature permafrost

- Sciences in Cold and Arid Regions, 7(4): 316-322

- http://dx.doi.org/10.3724/SP.J.1226.2015.00316

Article History

- Received: February 20, 2015

- Accepted: April 25, 2015

1 Introduction

Technological monitoring(TM)is performed during a period of dynamic environmental changes when heavy construction is occurring, such as when a roadway or railway is being built on high-temperature permafrost soil. The main purpose of TM is to provide targeted technological control of the construction operations; this is its fundamental distinction from the operational systems monitoring. For frozen soils this function is compatible with the prescriptive objectives for the control of temperature and humidity processes and soil conditions, predictive modeling and preparation of measures to ensure the base stability and stability of embankments(TSNIIS, 1990; NIIOSP them. NM Gersevanov, 2012b). New requirements for the assessment of stress-strain deformed conditions and the firmness of frozen and thawed soils on a real-time basis, with the expectation of commensurate operational adjustment of erection loads and impacts, have appeared.

The fundamental works on the construction and maintenance of subgrades(Shakhunyants, 1953; Goldstein, 1979)do not dwell upon the technological aspects of changes in the physical and mechanical properties of soils during construction. Nevertheless, the technical regulations On the Safety of Buildings and Structures(Federal law, 2009)state the following: "It should be proved subsequent to the results of calculations or any other justifications that the structures and foundations of the designed building or facility will not reach the limit state of strength and stability in the course of construction and operation." This requirement is applicable to the long-term cycle of weak subgrade consolidation before putting a road into service. The importance of monitoring during the whole life cycle of constructed facilities is pointed out in the works of several researchers(e.g., Ashpiz, 2002; Tsernant, 2013) and was proved at the Tsinkhai-Tibet Railroad(Li et al.,2006).

Technological design experience from the construction of railways and motorways in the Yakutia territory in the Sakha Republic of Russia, the Yamal territory in northern Siberia, and the Russian Arctic sub-polar territories(Kondratiev, 2001; Lutskiy et al.,2009)showed that it was most difficult to monitor the thaw-subsiding soils in high-temperature-permafrost areas. The conceptual focus of TM is the assessment of interrelations between the erection loads and soil properties in the course of in-process control of weak subgrade strength improvement processes. The predictive part of such monitoring is based upon experiments and systematization of observations in trial sections of subgrade(Isakov, 2010).

2 Technological monitoring of subgrade construction on high-temperature permafrostThe structure of complex technological monitoring of subgrade construction was developed and patented by MGUPS(MIIT)(Lutskiy et al.,2005)includes the following stages of TM:(1)diagnostics of soils condition in the right-of-way, (2)arrangement of drainage system;(3)in-process control of intensive weak subgrade strengthening.

The first diagnostic stage(TM-1)is intended to assess the design concept and the weak subgrade condition immediately before the commencement of works. TM-1 includes the collection and analysis of data for each layer: location, thickness, curve of temperature, humidity, thermal, physical and mechanical characteristics of consolidated and non-consolidated table, melting, thawed and boundary plastic frozen soil layers. All these data and consequently the deformation of layers will vary in the course of works.

Subsequent to the results of TM-1 the predictive modeling of final subsidence and subgrade stability in accordance with the method statement SP 25.13330.2012(NIIOSP them. NM Gersevanov, 2012b) and VSN 61-89(TSNIIS, 1990)is necessary. Instantaneous settlement, compaction, and filtration drainage take place in the melting argillaceous soil layer. Partial consolidation is possible in the course of thawing because the rate of soil compaction by gravity(depending on water permeability)is less than the rate of thawing(Ashpiz and Vavrinuk, 2012). Migratory viscous deformation is specific to the plastic frozen soil layer. The maximal vulnerability of frozen soils arises in case of melting layer expansion and humidity increase in the under-slope areas of road embankments. Here, technological loads act on the plastic frozen soil layer and can cause soil creep.

The equipment for TM-1 includes depth marks of geological horizons, piezometers, sets of thermistor chains, and data loggers. Seismic exploration and remote probing devices, particularly thermal cameras and georadars(GPRs), are used to determine the boundaries between frozen soils and taliks. The findings on the initial structure and the prediction of subgrade on-load stability in the course of works shall be the result of the TM-1 stage of this complex technology.

At the second stage(TM-2), the monitoring in the course of the drainage system arrangement should improve its efficiency: soil humidity decrease due to migration, and water drainage from the active zone. The drainage includes transverse or longitudinal channels, a protective layer with l and scape fabric, and bypass drain ditches; it should be installed in the autumn at the beginning of freezing and moisture migration under frost heave.

The TM-2 stage includes the function of soil conditions control. During the thaw period in spring, deformations of subgrades, accompanied by viscoplastic flow, are possible due to filtration consolidation of melting soils. A protective s and layer and channels will speed up the movement of accumulated water into bypass ditches. In this case an assessment of the subgrade settlement and the soil consolidation curve is necessary, including the melting layer subsidence at the maximal thaw penetration, compaction settlement of table soil under gravity and the protective layer weight, and subsidence of the plastic frozen soil layer under the weight of all the superjacent layers.

Assessment of the subgrade deformability is based on the principle of water and ice equilibration in frozen soils -- establishing dynamic equilibrium between the amount of unfrozen water and ice content when there is environmental(temperature and pressure)variation. Monitoring of water migration into the protective layer, the total moisture content in the active zone, the temperature curve, and the volume-to-volume ratio of unfrozen water and ice is provided at the TM-2 stage.

The equipment for TM-2 includes benchmarks, inclinometers, and depth marks in order to determine the actual subsidence dynamics. Sorption sensors are installed to measure humidity.

The TM-2 stage includes the analytical phase. Weakness, variability of mechanical properties, and potential creep of every layer of melting, freezing, and frozen soils under the influence of loads and temperature variations should be taken into consideration during the thawing process. It is important not only to determine the estimated mechanical properties(e.g., compressibility of frozen and melting soils, and their resistance to st and ard pressure and shear)but also to predict the possible changes during the long-term construction(Liu and Peng, 2009).

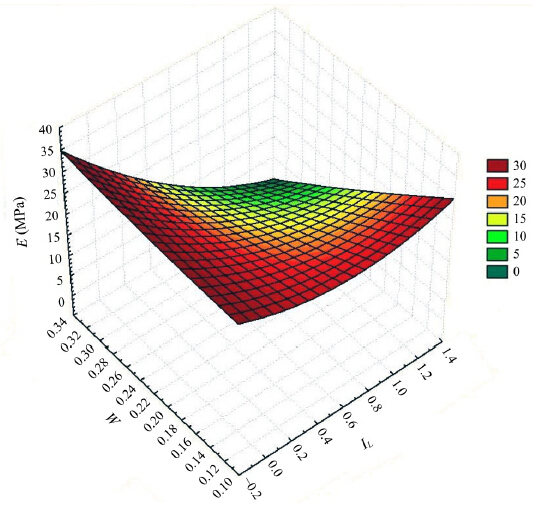

In order to predict these processes, we conducted statistical investigation(SP STATISTIKA, 3D Surface Plot)of cohesive soil characteristics in the areas where the new Obskaya-Salekhard Railway was being designed. We pre-selected the significant factors by multi-factor analysis of the temperature profile and stress-strain deformed condition of the soils, using relevant software packages. The primary objective of the diagnostics was to assess the interrelations of mechanical and thermal processes in the soils and to calculate the most dangerous combinations thereof. We determined the concurrent and interdependent variation of the soil characteristics, and found that in the course of thawing, high humidity(W) and the related index of liquidity(IL)result in the decrease of the deformation modulus(Е)for cohesive soils. This is the reason for extremely negative developments of soil outsqueezing from under road embankments. The maximal increase of deformability appears with a high index of liquidity prior to water removal(Figure 1). Based on 48 measurements in the trial area, regressional dependence was apparent(R = 0.84; F = 15.4; p = 0; N = 48):

|

| Figure 1 Dependence of the deformation modulus Е on humidity W and the index of liquidity IL for cohesive soils |

| $E = 31.4 - 1.47 - 21.44Y + 7.40{X^2} - 87.05XY + 36.50{Y^2}$ | (1) |

For rapid soil consolidation and safe performance of the construction, it is necessary to predict the deformation modulus and subsidence for each soil layer. The dependence of the modulus Е(MPa)on adhesion C(MPa; 0.01, …, 0.05) and the porosity ratio KP(0.4, …, 1.0)of thawed cohesive soils is expressed by:

| $E = 33.1 - 31.1{K_P} + 317.8C$ | (2) |

This regressional dependence(R = 0.74; F = 27.9; p = 0)demonstrates the dangerous interrelation of mechanical and thermal processes: the maximal deformability(fivefold to sevenfold decrease of the modulus E)is related to the combination of high porosity and low adhesion of soils immediately after thawing. In order to reduce subsidence, the compaction of soils under permissible load, and consequently the decrease of the KP ratio resulting in the increase of adhesion(C) and the modulus E, are provided at the TM-3 stage.

The principle of in-process load control is the following. The adjustment of loads up to the maximum permissible level aimed to reduce soil humidity, in combination with drainage, increases the soil strength. Uncontrollable erection loads promote an adverse interrelation of mechanical and thermal processes and , in a certain predictable combination, can result in continuous soil creep in the embankment base.

The third stage of monitoring(TM-3) accompanies intensive subgrade compaction after thawing in order to improve the soil strength characteristics and to remove water as long as the soil has a higher coefficient of permeability. The calculation of the permissible stress and process load(РP)in the base depth, in accordance with the method statement by Lutskiy et al.(2013), is necessary to control intensive compaction:

| ${P_P} \le ({P_S} - {P_{PORE}})$ | (3) |

The condition of each soil layer with time and the toughness of soils, assessed with the model developed by Konovalov et al.(2002), should be taken into consideration for the calculation of safe(shear)load:

| ${P_{rt}} = \left( {{\tau _{rt}} + {\eta _r} \cdot \frac{{{\rm{d}}\gamma }}{{{\rm{d}}t}}} \right)$ | (4) |

The singular focus of this intensive technology is soil compaction and water removal in the maximum permissible load mode. The monitoring at this stage should provide individual load control for each layer with due account for its condition at the time of the work performance. The operating regime of compactors should be revised based on the results of soil testing(in accordance with the requirements of GOST 20276-2012(NIIOSP them. NM Gersevanov, 2012a)), and the calculation of a safety factor for each layer of the base. Light-weight compactors with weight not exceeding 100 kN, and basic vibratory compactors with vibrators switched off, can be used for the first pass.

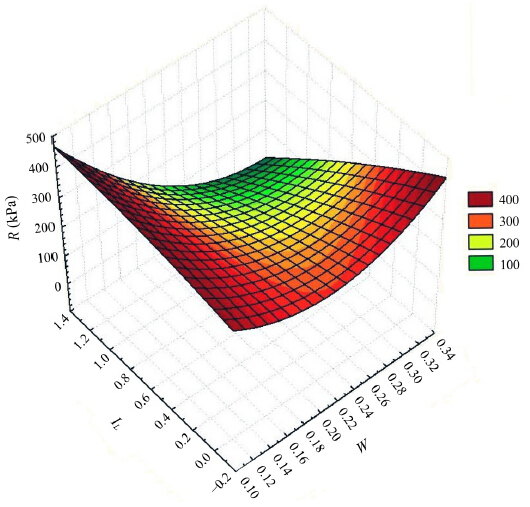

Compaction and soil humidity reduction increase soil strength and at the same time decrease the base deformations(Figure 2). This conclusion was confirmed by the regressional dependence for cohesive thawed soils we found when the subgrade support was obtained as a result of engineering surveys at the Obskaya-Salekhard Railway:

|

| Figure 2 Interdependence of design resistance R(kPa)on the index of liquidity IL and humidity W for thawed cohesive soils |

| $E = 19.65 - 48.43W + 0.05R$ | (5) |

In-process interactions of mechanical and thermal processes in the course of construction may result in dangerous combinations of characteristics determining the minimal bearing capacity of the base. Thus, synchronous control of conformance of the current soil characteristics and the adjustable parameters of the compactor(amplitude, frequency, traveling speed, and type of vibration)is required. In-process control of loads and soil consistency enables the flexibility to react in real time to any signs of ultimate limit state in each soil layer. If the loading performance of the compactor is increased, the content of non-frozen water in the upper layer of frozen soil will grow. As a result, the bearing capacity is reduced. Schreder(2011)describes an on-board consistency monitoring system that can efficiently monitor and optimize the loading performance of the compactor.

The TM-3 stage is implemented on the basis of field soil testing and geocryologic surveys in the trial area during the period of in-process load control. The daily discrete monitoring cycle corresponds to the technologically controlled compaction process and the need to consider the context of the soil structural strength changes before the next stage of load application(Konovalov et al.,2002). Due to vibration loads, determination of the soil thixotropy limits should be included in the testing program.

The equipment for TM-3 includes automated control systems for the operating modes and compaction quality of vibration compactors, and mobile systems for instant testing of physical, mechanical, and thermal properties of frozen and melting soils in the field, including load cells, piezosensors, pore pressure sensors, sets of thermistor chains, and data loggers. Daily control of water removal and variation of the permeability coefficient, as well as prediction of subsidence stabilization, improves the operational management of the construction processes, particularly in determining the time limits and the load increase schedule for soil compacting machinery.

The TM-3 stage should demonstrate the differential settlement dynamics(Shashkin, 2010)during the compaction of each layer, specifically to define the phases of:(1)discontinuous creep, based on the deceleration of deformations and stress that should not exceed the soil creep-rupture strength;(2)continuous creep where the rate of deformation is constant but stress exceeds the creep-rupture strength; and (3)developing creep evident as soil water outsqueezing.

If the subsidence is occurring in a predictable mode, the compacting load can be increased. If there is any acceleration of subsidence, the compaction process should be stopped and the pore pressure, adhesion, and the angle of internal friction should be measured. Thus, it is important to improve the base soil consistency before the embankment construction by means of humidity reduction, which leads to the decrease of non-frozen water content in the transition layer.

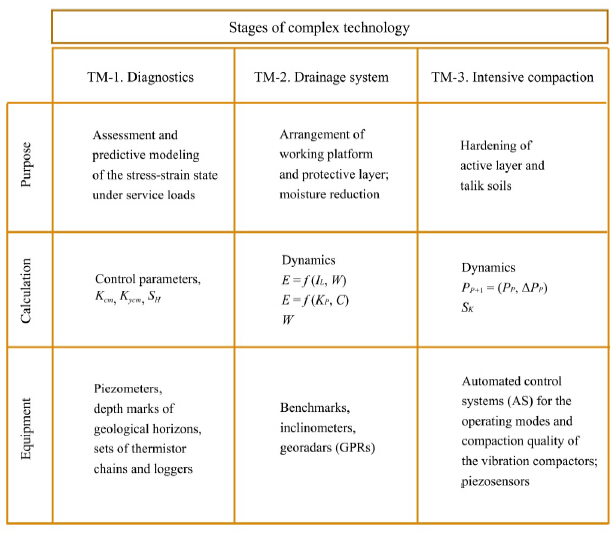

The third stage of this complex technology should be completed when the design values of settlement, soil safety factors, and the stability of embankments under service load is reached. Figure 3 is a block diagram of the monitoring stages for the complex technology.

|

| Figure 3 Block diagram of the complex technology stages monitoring.Kст, Kуст - coefficients of the base stability and stability of embankments, respectively; W - humidity; IL -index of liquidity; KP - porosity ratio; С - adhesion; PP, ΔPP - process load and its growth; SH, SK - initial and final settlement |

The capacities of advanced vibration compactors manufactured by Bomag, Hamm and Dynapaс companies and equipped with automated systems for:(1)compaction quality control and infinitely variable amplitude adjustment from the minimum value to the maximum one;(2)continuous monitoring of the level of soil compaction;(3)on-board computerized global positioning systems comply with the requirements of the TM-3 stage. Their systems register the received data on the operation of the compactor and the achieved consistency of soils, and transmit them to an office computer. On-board computers enable optimal adjustment of vibration parameters within the range of amplitudes, and the compactor traveling speed, depending on the level of soil compaction. Adjustable compaction and monitoring of the bearing capacity for each soil layer speed up the consolidation of soils after thawing during the most favorable periods for water migration and removal.

The monitoring control functions should correlate with the work execution schedule. In the case of long-term loads on dispersive plastic frozen soils(especially high-temperature soils), the deformation can transform into creep, and the base will lose its stability exactly along the transition layer. Although it is sufficient to be guided by instantaneous soil strength measurements to determine the permissible compactor load on the frozen layer of the base, during the embankment construction the creep-rupture strength should be controlled because exceeding of limits thereof will result in creep development. For example, tensile strength under uni-axial compression of clay loam with low ice content is 1.5-2.0 times lower than the creep-rupture strength and 3 times lower than instantaneous strength. The condition of the under-slope part of the embankment in spring, with large amounts of non-frozen water, is especially dangerous for technological design because load stresses(especially long-term, dynamic ones)promote shear stress. The external manifestations include cracks and slipping of the embankment slopes. It is necessary to look to ultimate shear resistance in order to calculate the permissible load for such areas.

This stated scope of monitoring was included in the process regulations developed by MGUPS(MIIT)(Lutskiy et al.,2009, 2013). For construction of sections of the new Obskaya-Bovanenkovo-Karskaya Railway line, the monitoring included analysis of geocryologic processes and control of the process chart parameters for single-stage and two-stage construction of embankments, arrangement of ice roads, and procurement and transportation of dry frozen soil from pits near the line. The application of these regulations at the subgrade section of the Tommot-Yakutsk line demonstrated that was possible to reach complete settlement of 95% in two months. In that construction, the embankment had a height of 2.15-m and a 1.70-m layer of very soft loam at the base; a Hamm 3520P compactor with a weight of 19.9 t was selected for intensive compaction.

3 ConclusionsThe objective of technological monitoring is to investigate and predict the mechanical, thermal, and physical processes taking place in layers of melting, thawed, and frozen soils for the operational adjustment of erection loads in order to increase structural strength and to reduce deformability of roadways constructed on permafrost soils. The adjustment of in-process loads on the soils to the maximum permissible limits is aimed at reducing humidity; in combination with drainage and monitoring, this improves the strength characteristics of the embankment foundations. Uncontrollable loads promote adverse interactions of mechanical and thermal processes which, in certain combinations, can lead to continuous soil creep in each layer.

The implementation of the complex technology described here is related to the requirements for soil testing in the field and geocryologic investigations of the base bearing-capacity dynamics in a trial subgrade area during the period of in-process load control.

Acknowledgments: This research was supported by Federal State-Funded Educational Institution of Higher Vocational Education "Moscow State University of Railway Engineering"(MGUPS(MIIT)), JSC "Yamaltransstroy" and LLC "Transstroymekhanisatsiya".| Ashpiz ES, Vavrinuk TS, 2012. Assessment of embankments stability in view of consolidation processes in foundation soil in permafrost areas. In: New Technology of Railway Engineering. Proceedings, 2nd International Conference on Railway Engineering. Beijing:China Railway Publishing House. |

| Ashpiz ES, 2002.Subgrade Monitoring during Operation of Railroads. Moscow: Put-Press. |

| Federal law, 2009. Federal law of 30.12.2009 No. 384: The Technical Regulations On the Safety of Buildings and Structures. |

| Goldstein MN, 1979.Mechanical Properties of Soils. Moscow: Stroyizdat. |

| Isakov AL, 2010. Comparative analysis of soil deformation models for the calculation of stress-strain deformed condition of subgrades. In: IsakovAL, KovalevYL(eds.). Report of Siberian State University of Railway Engineering (SSURE). Novosibirsk: SSURE, 23: 63-68. |

| Kondratiev VG, 2001. Active Methods of Subgrade Base Reinforcement on Permafrost Soils. Chita, Russia: ZabtransCo.. |

| Konovalov PA, Zekhniev F, Bezvolev SG, 2002. Assessment of performance for weak subgrade pre-consolidation by supercharge loading. Bases, Foundations and Soil Mechanics, 2: 18-22. |

| Li GY, Li N, Quan XJ, 2006. The temperature features for different ventilated-duct embankments with adjustable shutters in the Qinghai-Tibet railway. Cold Regions Science and Technology, 44: 99-110.DOI: 10.1016/j.coldregions.2005.08.002. |

| Liu JK, Peng LY, 2009. Experimental study on the unconfined compression of a thawing soil. Cold Regions Science and Technology, 58: 92-96. DOI: 10.1016/j.coldregions.2009.03.008. |

| LutskiySYa, Apshiz ES, Dolgov DV, 2005. Road Bed and the Construction Method for It. Patent No. 2005104907/09(006247). Moscow: FIIP. |

| LutskiySYa, Shepitko TV, Cherkasov AM, 2013. Composite technology of earthwork construction on taliks in cryolithic zones. Cold Regions Science and Technology, 5: 577-581. DOI: 10.3724/SP.J.1226.2013.00577. |

| LutskiySYa, Shepitko TV, Tokarev PM, et al., 2009.Construction of Transport Routes in the Northern Regions.Moscow:LATMES. |

| NIIOSP them.NM Gersevanov, 2012a. GOST 20276-2012, Soils. Field methods for determining the strength and deformability.Moscow: Research, Design and Survey and Design Institute of Technology Foundations and Underground Structures (NIIOSP) them. NM Gersevanov. |

| NIIOSP them.NM Gersevanov, 2012b. SP 25.13330.2012, Code of Practice: Foundations and Groundwork on Permafrost Soil. Moscow: Research, Design and Survey and Design Institute of Technology Foundations and Underground Structures (NIIOSP) them. NM Gersevanov. |

| Schreder R, 2011. Compaction. Augsburg, Germany: HAMM AG/Wirtgen Group. |

| Shakhunyants GM, 1953. Railroad Subgrade.Moscow: Transzheldorizdat. |

| Shashkin AG, 2010.Description of argillaceous soil deformation behavior with viscoelastic plastic model.Geotechnical Engineering, 4: 28-32. |

| Tsernant AA, 2013. Innovative technologies for the control of soil mass temperature for transport infrastructure facilities in Arctic regions. Construction Materials, Equipment and Technologies of the XXI Century, 3: 26-31. |

| TSNIIS, 1990.VSN 61-89, Surveys, design and construction of railroads in permafrost areas.Moscow: Research Institute of Transport Construction (TSNIIS). |

2015, 7

2015, 7